- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

What is a Woodworking CNC Machine and How Does it Work?

In the world of woodworking, CNC technology has revolutionized how craftsmen create intricate designs. A woodworking CNC machine combines precision and creativity. According to expert John Miller, "These machines open new doors for artisans." They allow for consistent replication of complex patterns.

The woodworking CNC machine operates using computer software. It translates designs into specific movements for cutting tools. This technology eliminates many traditional limitations. However, some may argue it can diminish the uniqueness of handmade work. In pursuit of perfection, nuances of human touch can be lost.

Yet, many artisans embrace this evolution. They find ways to blend technology with traditional skills. The balance between these methods offers exciting possibilities. As craftsmanship evolves, the woodworking CNC machine remains a crucial tool for modern woodworkers.

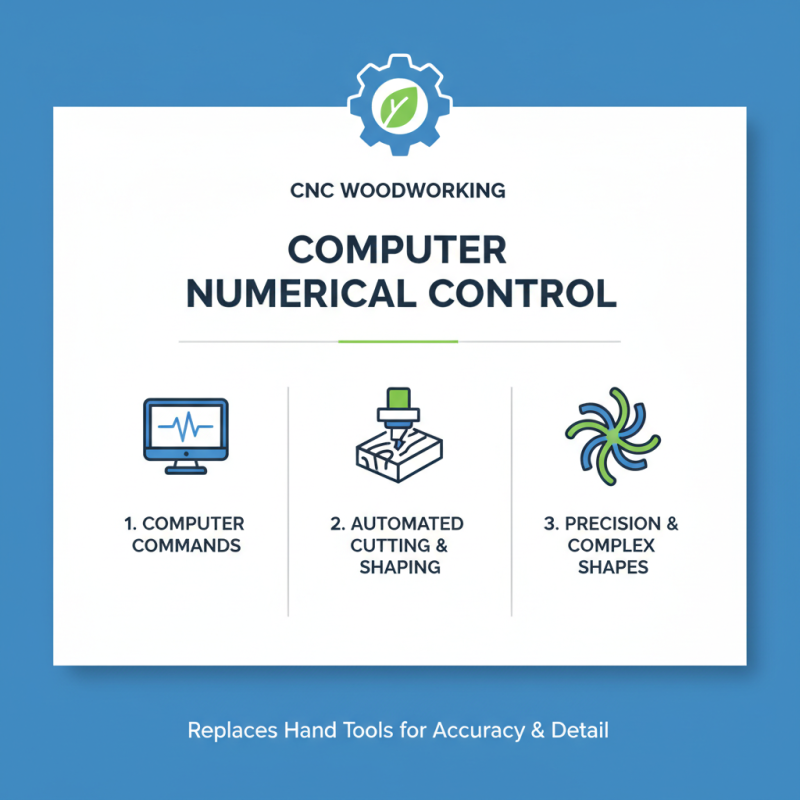

What is a CNC Machine in Woodworking?

A CNC machine in woodworking stands for Computer Numerical Control. It's a tool that automates the process of cutting and shaping wood. It operates through commands from a computer. These machines can perform complex shapes with precision that hand tools cannot achieve.

When using a CNC machine, the software converts designs into specific coordinates. The machine then follows these coordinates. You can create intricate patterns or simple cuts. Each project brings challenges. Sometimes, the machine misreads the design. Always double-check your software settings.

Tips: Always ensure your wood is securely clamped. Loose material can lead to errors. Take time to set up the machine properly. Rushing can cause mistakes. After completing a project, review the output. Understand where improvements can be made. This reflection will guide your next tasks.

Key Components of a Woodworking CNC Machine

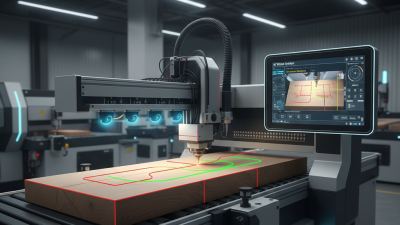

A woodworking CNC machine is a sophisticated tool that automates the cutting and shaping of wood. At the heart of this machine are several key components that ensure precision and efficiency. The controller serves as the brain of the operation, interpreting design files and directing movement. This electronic device is crucial for executing intricate patterns and designs in a timely manner.

Next, the spindle spins the cutting tool at high speeds. It can handle various bits, depending on the desired finish. A well-timed spindle can make all the difference during a complicated cut. However, maintaining the spindle is vital. A poorly maintained spindle may lead to subpar results, forcing operators to rethink their approach.

The framework or chassis provides stability. It must be sturdy enough to withstand the forces generated during operation. If the frame is weak, vibrations can lead to inaccuracies. Operators often overlook this aspect, which can create a headache down the line. Additionally, the bed supports the workpiece and aligns it for cutting. If misaligned, it can ruin an otherwise perfect project, emphasizing the need for meticulous setup every time.

How CNC Machines Operate in Woodworking Projects

CNC machines in woodworking are fascinating tools. They automate the cutting and shaping of wood. Using computer software, they create precise designs. A user simply inputs specifications into the CNC system. The machine then translates this data into precise movements. This can lead to intricate patterns and shapes that are hard to achieve manually.

Setup can sometimes be tricky. Users need to ensure that the machine is calibrated correctly. Even a slight mistake can lead to flaws. Materials like wood can also vary in density and texture. This affects the outcome. Experimentation is often necessary. It’s vital to understand how different woods react to the machine's settings.

Incorporating CNC in projects speeds up the production process. However, it requires constant monitoring. Users may deal with technical glitches or software updates. There is a learning curve, as well. Mastering the capability of a CNC machine takes time. It's essential to remain patient and willing to learn from mistakes. This journey often leads to greater creativity in woodworking.

What is a Woodworking CNC Machine and How Does it Work?

| Feature | Description | Applications | Materials Used |

|---|---|---|---|

| Precision | CNC machines provide high accuracy and repeatability in cuts. | Furniture making, cabinetry, and intricate designs. | Hardwoods, softwoods, plywood, and composites. |

| Automation | CNC machines can operate with minimal human intervention. | Mass production and prototyping. | MDF, particle board, and hardwood. |

| Flexibility | Easily programmable for various designs and cuts. | Custom woodworking projects and artistic pieces. | Exotic woods and laminates. |

| Speed | CNC machines can produce cuts much faster than manual methods. | Large-scale production lines and rapid prototyping. | All types of wood and synthetic materials. |

| Software | Operated using CAD and CAM software for design and production. | Designing complex shapes and patterns for woodworking. | Compatible with a variety of woodworking materials. |

Common Applications of CNC Machinery in Woodworking

CNC machinery is transforming the woodworking industry. In 2021, the global CNC machine market was valued at approximately $63 billion. It is projected to grow steadily. Woodworkers are leveraging CNC technology to increase efficiency and precision.

Common applications include furniture making, cabinetry, and intricate designs. These machines can cut, carve, and engrave materials with remarkable accuracy. For instance, CNC routers can create complex shapes that hand tools cannot. This capability allows for more creative designs and faster production times.

However, reliance on technology does have drawbacks. Operators need specialized training to run these machines effectively. A lack of skill can lead to errors or wasted materials. Additionally, maintaining the equipment is crucial. Neglecting regular upkeep can result in breakdowns or subpar work. Balancing technology and traditional skills remains a challenge in the industry.

Advantages of Using CNC Technology for Woodworking

CNC technology has transformed woodworking. It allows for precise control over cutting and shaping materials. An industry report from the Association for Manufacturing Technology indicates that CNC machines can increase production speed by up to 60%. This means woodworkers can efficiently complete complex designs in less time.

One clear advantage is the reduction in human error. The machines follow programmed designs, ensuring consistency in product output. For example, intricate patterns that once took hours to craft by hand can now be done in minutes. However, there are challenges. Initial setup costs for CNC machines can be high, and not every workshop can afford them.

Moreover, skilled operators are needed to manage these machines. This creates a dependency on technology. An operator’s error, though less common, can still lead to wasted materials. Therefore, while CNC technology boosts efficiency, it also requires careful consideration and training to maximize its benefits.

Woodworking CNC Machine Usage Statistics

Related Posts

-

2026 Top Woodworking CNC Machines: Features, Benefits, and Buying Guide

-

Top 10 Benefits of Using a Wood CNC Machine for Your Projects?

-

10 Essential Tips for Maximizing Efficiency with Your CNC Mill

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

-

2026 Best CNC Wood Carving Machine for Precision and Creativity?

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project