- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Why Choose a Rotary Screw Air Compressor for Your Industrial Needs?

In the evolving landscape of industrial operations, the choice of air compressor technology can significantly impact efficiency and productivity. Among the available options, the rotary screw air compressor stands out for its reliability and performance. According to industry expert, Dr. Lisa Reynolds, a leading authority in compressed air systems, "The rotary screw air compressor provides a perfect blend of power, efficiency, and continuous operation, making it an indispensable asset for modern manufacturing."

With its capacity to deliver a continuous supply of compressed air, the rotary screw air compressor is ideal for various industrial applications, including pneumatic tools, assembly lines, and specialized machinery. Its design minimizes wear and tear, ensuring longevity and reducing maintenance costs, which are pivotal for businesses aiming to enhance their operational effectiveness.

As industries continue to face the demands of increased production and energy efficiency, the rotary screw air compressor emerges as a robust solution capable of meeting these challenges head-on. This introduction sets the stage for exploring the numerous advantages and applications of rotary screw air compressors, making a compelling case for their integration in industrial settings.

Advantages of Rotary Screw Air Compressors in Industrial Applications

Rotary screw air compressors have become a preferred choice for many industrial applications, thanks to their efficiency and reliability. According to market analysis, the screw compressor sector is projected to reach USD 22.9 billion by 2035, with a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2025 to 2035. This trend reflects the growing demand for consistent and high-quality compressed air in various industries, from manufacturing to food processing.

One of the key advantages of rotary screw compressors is their ability to deliver a continuous flow of compressed air, which is essential for high-demand operations. Unlike reciprocating compressors, which tend to deliver air in bursts, rotary screw compressors operate smoothly, minimizing pressure fluctuations and enhancing operational efficiency. Furthermore, the compressor oil market is also on an upward trajectory, expected to reach USD 11.5 billion by 2035, driven by the rise in industrial automation and the transition towards synthetic formulations, which work synergistically with rotary screw compressors to improve performance and extend equipment life.

Advantages of Rotary Screw Air Compressors in Industrial Applications

Understanding the Efficiency of Rotary Screw Air Compressors

Rotary screw air compressors are increasingly recognized for their efficiency in industrial applications. Unlike traditional reciprocal compressors, which operate in a stop-and-start manner, rotary screw compressors utilize a continuous flow of air. This design ensures smooth operation, reducing wear and tear on components while providing a steady supply of compressed air. The result is a more consistent performance, which is especially beneficial for industries that rely heavily on sustained airflow for production processes.

Moreover, the energy efficiency of rotary screw air compressors is a significant factor in their choice for industrial use. These compressors can achieve remarkable efficiencies, often highlighted by their ability to operate at lower horsepower at higher outputs compared to alternatives. This translates to reduced operational costs, as less energy is consumed for the same output. Additionally, many modern models incorporate advanced technologies such as variable speed drives, which adjust the compressor’s speed based on air demand, further optimizing energy use and minimizing waste. Thus, for any industrial facility looking to enhance productivity while keeping energy costs manageable, rotary screw air compressors offer a compelling solution.

Key Features That Make Rotary Screw Air Compressors Stand Out

Rotary screw air compressors have gained popularity in various industrial applications due to their unique features that enhance performance and efficiency. One key feature that sets rotary screw compressors apart is their continuous operation capability. Unlike other types, such as reciprocating compressors, rotary screw compressors can run non-stop. This continuous operation ensures a steady supply of compressed air, which is essential for processes requiring uninterrupted performance.

Another distinctive characteristic is their energy efficiency. Rotary screw compressors are designed to consume less energy while delivering high air output, leading to significant cost savings over time. With advancements in technology, these compressors often come equipped with variable speed drives that can adjust motor speed to match air demand, further optimizing energy use.

Tips: When selecting a rotary screw air compressor, consider factors like the necessary airflow rate and pressure. Additionally, it’s beneficial to look for models with built-in monitoring systems, which can provide real-time feedback on performance and maintenance needs. This proactive approach can help avoid downtime and extend the lifespan of your equipment. Choosing the right compressor can have a lasting impact on your operational efficiency and overall productivity.

Comparison of Rotary Screw and Reciprocating Air Compressors

When considering air compressors for industrial applications, the choice often boils down to rotary screw and reciprocating models. Rotary screw air compressors are known for their continuous operation, providing a constant flow of compressed air. This is particularly beneficial for industries that require a steady output without fluctuations, such as manufacturing and food processing. Their design allows for a quieter operation and lower maintenance compared to reciprocating compressors, making them ideal for environments where noise reduction is crucial.

On the other hand, reciprocating air compressors work in a more traditional manner, using pistons to compress air in cycles. While they are typically more affordable upfront and better suited for intermittent use, they may not be the best choice for operations that demand high volumes of air over extended periods. Additionally, reciprocating compressors are generally noisier and require more routine maintenance, which can increase operational costs in the long run.

In summary, for businesses that need reliability, efficiency, and lower overall maintenance, rotary screw air compressors present a more favorable option compared to their reciprocating counterparts.

Maintenance Benefits of Using Rotary Screw Air Compressors for Industry

Rotary screw air compressors are increasingly recognized in industrial settings for their maintenance benefits. Unlike reciprocating compressors that require frequent and intensive maintenance, rotary screw versions benefit from fewer moving parts and less wear over time. This translates into longer intervals between required maintenance, reducing downtime and associated costs. Additionally, advancements in technology have led to the development of oil-free models that not only enhance reliability but also minimize the need for lubricant changes, further streamlining maintenance processes.

Rotary screw air compressors are increasingly recognized in industrial settings for their maintenance benefits. Unlike reciprocating compressors that require frequent and intensive maintenance, rotary screw versions benefit from fewer moving parts and less wear over time. This translates into longer intervals between required maintenance, reducing downtime and associated costs. Additionally, advancements in technology have led to the development of oil-free models that not only enhance reliability but also minimize the need for lubricant changes, further streamlining maintenance processes.

The move towards rotary screw compressors aligns with the growing demand for efficient and sustainable solutions in various industries. With a continuous and stable output of compressed air, these compressors help businesses maintain operational consistency. Innovations such as the new ECO-Rotary model exemplify the commitment to reliability and efficiency, catering to diverse industrial applications. Furthermore, local service support enhances the overall maintenance experience, ensuring that businesses can quickly resolve any issues that may arise, ultimately leading to an optimized production environment.

Related Posts

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

-

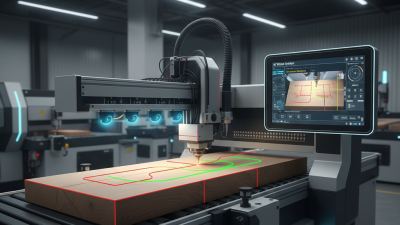

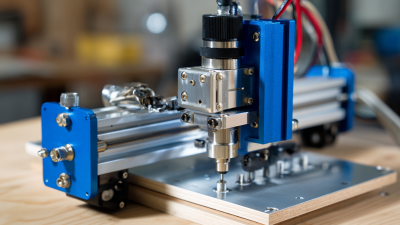

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

-

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping