- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2026 How to Use Wood CNC Machines for Perfect Craftsmanship?

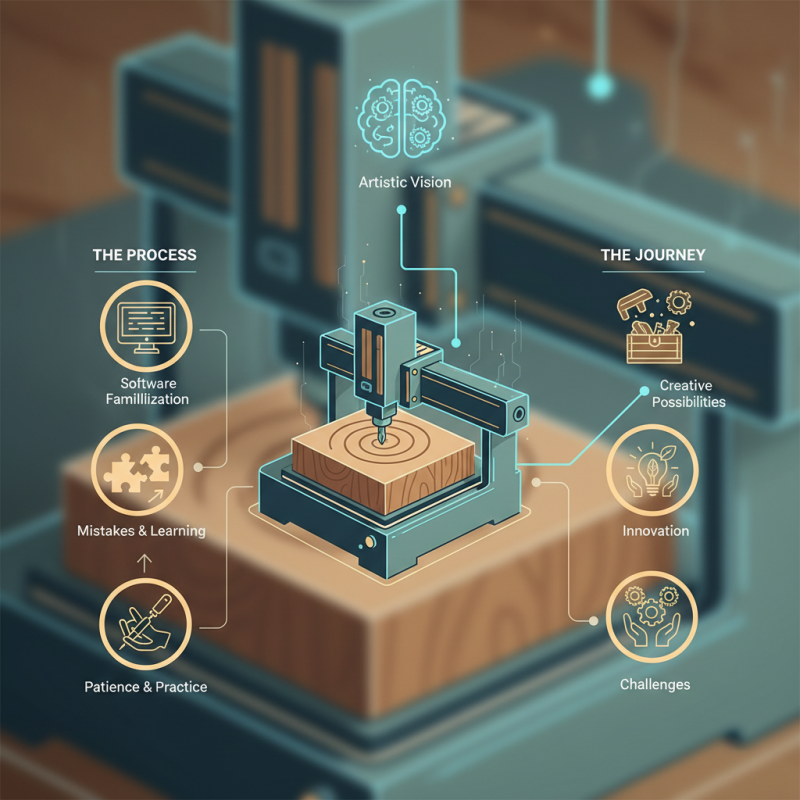

In the world of craftsmanship, precision matters. Wood CNC machines offer an opportunity to achieve perfect details. These tools can transform your artistic visions into reality. However, using wood CNC is not without its challenges.

The process can be daunting at first. Familiarizing yourself with the machine's software is essential. Mistakes can happen, and even small errors can lead to significant setbacks. Learning from these missteps can lead to improvement.

Creating beautiful wooden pieces requires patience and practice. Each project is a chance to refine your skills. Remember, even seasoned craftsmen encounter issues. Embracing these challenges can lead to greater artistry and innovation. By mastering wood CNC technology, you unlock new creative possibilities.

Understanding Wood CNC Machines: Basics and Terminology

Understanding wood CNC machines starts with grasping key terminology and concepts. CNC stands for Computer Numerical Control. These machines automate the manufacturing process, making it efficient. Wood CNC machines can precisely cut, carve, and engrave various wood types. According to a recent industry report, the demand for CNC machinery has grown at a rate of 13% annually. This reflects an increasing reliance on technology in woodworking.

Operators often encounter challenges. For example, selecting the right feed rate can be tricky. Too fast a speed may lead to rough cuts or even tool breakage. Conversely, a slow rate might cause excessive wear on the tools. Awareness of these variables is crucial. Additionally, understanding different types of bits and their uses is vital. Incorrect bit selection can ruin a project, requiring additional time for repairs. Miscommunication about project dimensions can lead to expensive mistakes, underscoring the need for clarity.

As one delves deeper into CNC woodworking, continual learning is essential. The technology evolves rapidly, and staying updated on best practices enhances craftsmanship. Operators must reflect on previous projects for improvement. Mistakes, while frustrating, are learning opportunities in mastering wood CNC technology.

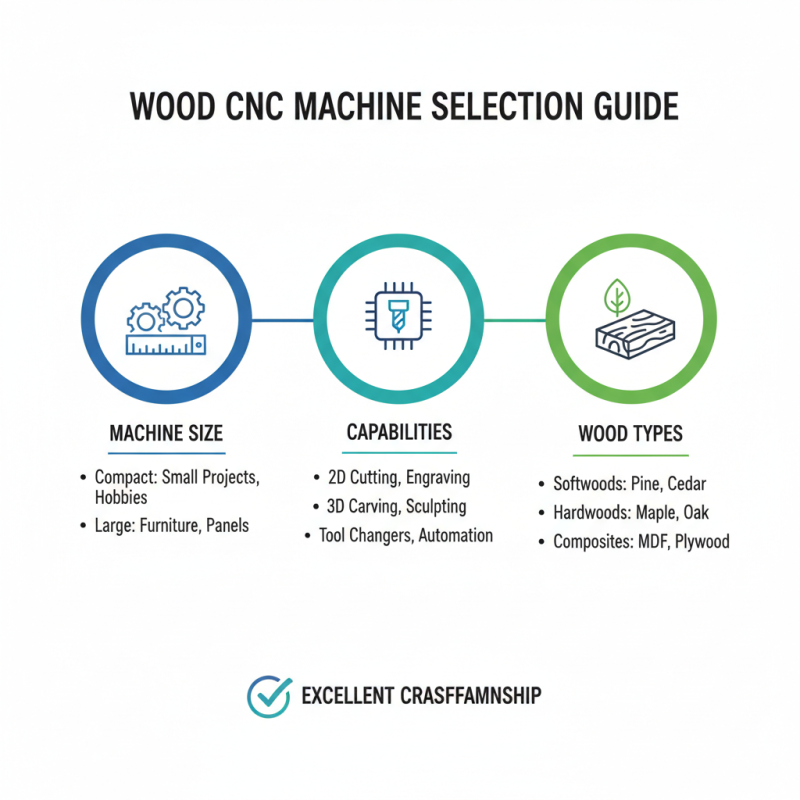

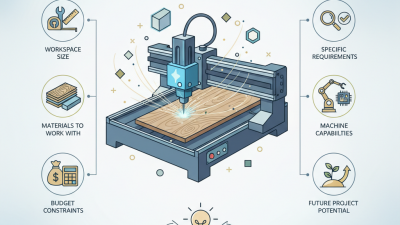

Selecting the Right Wood CNC Machine for Your Projects

Selecting the right wood CNC machine is vital for achieving excellent craftsmanship. Many options exist, but not all are suited for every project. Consider the machine’s size, capabilities, and types of wood you will use. A compact model might work for small projects, but a larger machine could be necessary for furniture.

Evaluate the specifications of the machines you are considering. Look at the cutting precision and speed. Some machines excel at intricate designs, while others may struggle. If you frequently switch between different materials, versatility will be key. However, the more features a machine has, the more complicated it can become to operate.

Don’t forget about support and learning curves. A powerful machine will not produce good results without experience. Mistakes will happen, and it’s important to learn from them. Try to connect with local makers or online communities. Their insights can help you avoid common pitfalls. Selecting the right CNC machine is a journey, and every choice along the way shapes your craftsmanship.

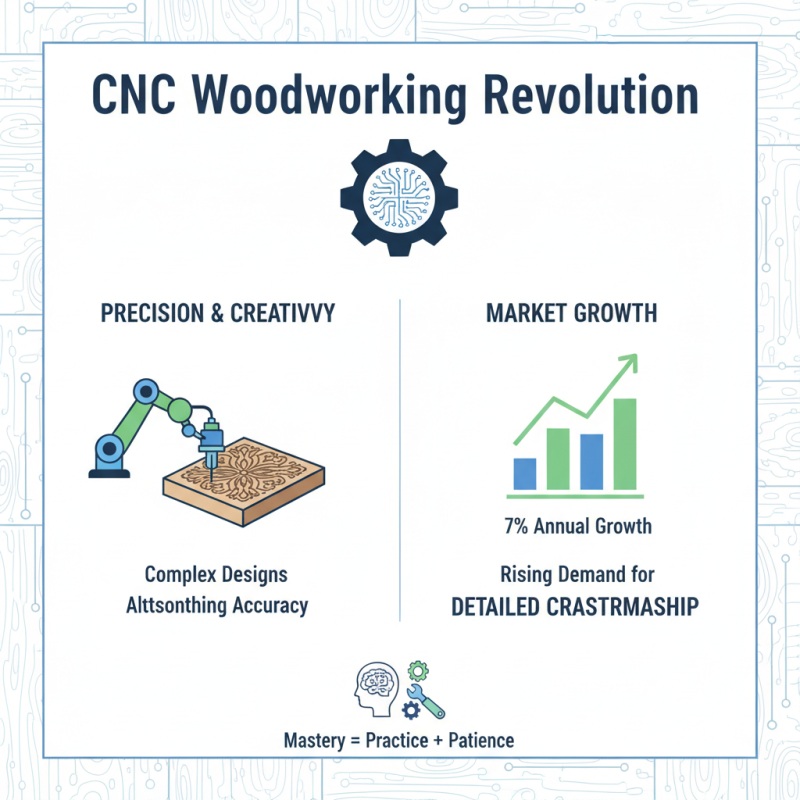

Essential Techniques for Precision Woodworking with CNC Machines

Using CNC machines in woodworking opens a new world of precision and creativity. According to recent industry reports, the CNC woodworking market is projected to grow by 7% annually. This growth highlights the rising demand for detailed craftsmanship. CNC machines allow woodworkers to create complex designs with astonishing accuracy. However, mastering these techniques requires practice and patience.

To achieve perfect craftsmanship, pay attention to material selection. Different woods behave differently when cut or carved. Understanding the properties of hardwood versus softwood is crucial. For instance, hardwoods offer durability but can be more challenging to machine. Softwoods are easier to work with but may not provide the same level of finish.

Programming the CNC machine is another critical aspect. Mistakes in code can lead to imperfect designs. A slight error can ruin an entire project. Many woodworkers find that trial and error is part of the journey. Testing different speeds and feeds can yield varying results. Gathering this data and reflecting on your process can enhance future projects. Embrace the learning curve and iterate on your techniques.

Tips for Finishing and Crafting High-Quality Wood Products

Using wood CNC machines can elevate your craftsmanship. However, perfecting your finishing techniques is critical for high-quality wood products. Here are some tips to guide you through the process.

Start with proper sanding. Use multiple grits, moving from coarser to finer. A common mistake is skipping grits. Each grit serves a purpose. Pay attention to difficult areas. They often require extra care. Inspect your work closely. Look for imperfections before applying any finish.

Next, choose your finish wisely. Oils, stains, and lacquers can alter the appearance. Test finishes on scrap wood first. This helps avoid mistakes on your final piece. It's easy to underestimate this step. Remember that less is often more. Apply thin, even coats. Allow adequate drying time between layers. Rushing this can lead to uneven textures.

Lastly, always clean your workspace after crafting. Dust and debris can mar your final product. Don't overlook the importance of a clean environment. Small details matter in woodworking. Each step impacts the final outcome. Embrace imperfections and learn from them. This reflection improves future projects.

2026 How to Use Wood CNC Machines for Perfect Craftsmanship? - Tips for Finishing and Crafting High-Quality Wood Products

| Aspect | Tip | Best Practice |

|---|---|---|

| Material Selection | Choose high-quality wood | Opt for hardwoods like oak or maple for strength |

| CNC Settings | Adjust feed rate and spindle speed | Test and calibrate based on wood type |

| Cutting Tools | Use sharp, appropriate bits | Carbide bits provide better durability |

| Finishing Techniques | Sand after cutting | Use finer grit for smoother finish |

| Assembly | Plan joints carefully | Use dowels or biscuits for strength |

| Maintenance | Clean CNC machine regularly | Check for wear on parts to ensure precision |

Troubleshooting Common Issues in Wood CNC Machining

CNC machines offer precise woodworking capabilities. However, issues can arise, affecting the final product. One common problem is misalignment. A misaligned workpiece can lead to uneven cuts. Check the machine’s calibration frequently. Even slight errors can compound and create significant mistakes.

Another frequent issue is tool wear. Dull bits can create rough edges or incomplete cuts. Regularly inspect your tools and replace them when necessary. Ignoring tool maintenance can lead to poor craftsmanship. Additionally, keep the bits clean. Built-up residue can also affect performance.

Dust and debris are other culprits. They can obstruct moving parts and affect precision. Maintain a clean workspace to avoid such problems. Pay attention to your feed rates; too fast can lead to chipping. Take time to adjust settings. Each project is unique and requires careful consideration.

Related Posts

-

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

2026 Top Woodworking CNC Machines: Features, Benefits, and Buying Guide

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

10 Essential Tips for Choosing the Right CNC Router for Your Projects

-

Why You Should Consider a CNC Router for Your Next Project