- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

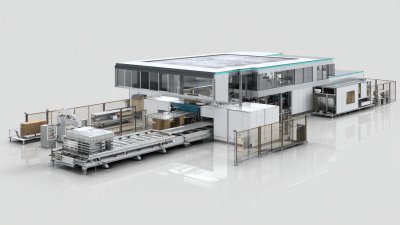

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

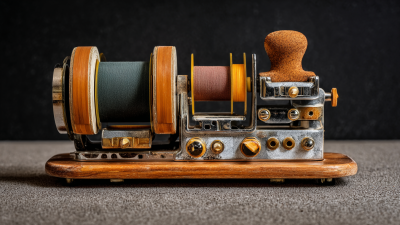

In recent years, the furniture industry has witnessed a remarkable transformation, largely driven by the advent of technology. One of the most significant innovations in this field is the wood CNC machine, which stands for Computer Numerical Control machine. This cutting-edge technology harnesses precision and efficiency, allowing furniture manufacturers to create intricate designs with remarkable accuracy.

In recent years, the furniture industry has witnessed a remarkable transformation, largely driven by the advent of technology. One of the most significant innovations in this field is the wood CNC machine, which stands for Computer Numerical Control machine. This cutting-edge technology harnesses precision and efficiency, allowing furniture manufacturers to create intricate designs with remarkable accuracy.

Unlike traditional woodworking methods, wood CNC machines automate the cutting, shaping, and engraving processes, significantly reducing production time while enhancing the quality of finished products. As a result, furniture makers can now offer a diverse range of customizable options to meet the unique needs of their customers. By unlocking new levels of precision and creativity, wood CNC machines are not just streamlining production but also revolutionizing the very essence of furniture design and craftsmanship, paving the way for a new era in the industry.

The Rise of Wood CNC Machines: Transforming Traditional Furniture Manufacturing

The rise of wood CNC machines is significantly transforming traditional furniture manufacturing, paving the way for enhanced efficiency, precision, and sustainability. According to industry reports, the global woodworking machinery market is projected to expand from $5.23 billion in 2025 to $7.88 billion by 2032, demonstrating a robust CAGR of 6.0%. This growth reflects a larger trend where advanced wood processing technologies are not only altering production methods but also empowering manufacturers to meet the increasing demand for customizable and intricate designs.

As the global CNC market is expected to grow from $101.2 billion to an impressive $195.6 billion by 2032—expanding at an annual rate of 9.9%—the adoption of CNC machines in woodworking has become indispensable. The integration of these machines allows for precision engineering and significantly reduces waste, aligning with modern sustainability goals. Furthermore, the woodworking CNC tools market is estimated to reach a valuation of approximately $3,335.4 million by 2033, indicating a growing appetite for automated solutions in the woodworking industry. This shift not only enhances productivity but also transforms how companies approach furniture design and manufacturing in an increasingly competitive market.

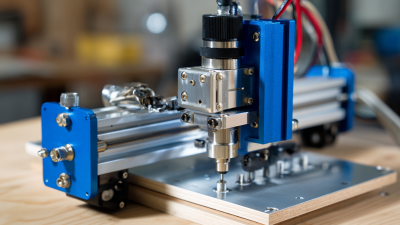

Precision Engineering: The Role of CNC Technology in Design Accuracy

CNC (Computer Numerical Control) technology has become a game-changer in the furniture industry, particularly in enhancing design accuracy and precision engineering. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.1 billion by 2026, driven by an increasing demand for high-quality furniture that meets specific consumer requirements. This surge underscores the pivotal role that CNC machines play in achieving unparalleled precision in woodworking, allowing manufacturers to create intricate designs with minimal waste and maximum efficiency.

Moreover, CNC machines offer consistent quality across production runs, significantly reducing the margin for human error. A survey from the Woodworking Network in 2022 revealed that 68% of manufacturers using CNC technology reported a substantial decrease in production time and an increase in design complexity. This precision not only enhances aesthetic appeal but also ensures that functional components fit perfectly, increasing overall customer satisfaction. As wood CNC machines continue to evolve, they will increasingly shape the future of furniture design, pushing the boundaries of creativity while solidifying their critical role in precision engineering.

Impact of CNC Technology on Furniture Design Precision

Reducing Waste and Enhancing Sustainability through CNC Machining

CNC machining technology is making significant strides in the furniture industry, promoting sustainability by drastically reducing waste. Traditional woodworking methods often generate substantial scrap material, whereas CNC machines utilize precision algorithms to optimize material usage. This not only conserves resources but also reduces the carbon footprint associated with furniture production. Companies that adopt CNC technology can create intricate designs with minimal waste, aligning with contemporary sustainability goals.

**Tips:** When considering the transition to CNC machining, focus on selecting machines that allow for advanced nesting software to maximize material efficiency. Additionally, regularly evaluate your production processes to identify potential areas for waste reduction.

Integrating CNC technology facilitates a more eco-friendly approach by enabling manufacturers to recycle waste materials effectively. By taking advantage of advanced capabilities such as automated cutting and efficient supply chain management, furniture makers can significantly lessen their environmental impact while maintaining high-quality production standards. This transformation contributes to a more sustainable future for the industry, allowing companies to meet both consumer demands and environmental regulations.

**Tips:** Invest in training for your workforce to fully leverage CNC capabilities, ensuring they understand both the machines and the sustainability goals of your organization.

Cost Efficiency in Production: How CNC Machines are Shaping the Furniture Market

CNC (Computer Numerical Control) machines have become a game-changer in the furniture industry, providing unparalleled cost efficiency that reshapes traditional manufacturing processes. According to a report by Allied Market Research, the global CNC machine market is projected to reach $117 billion by 2026, growing at a CAGR of 6.2% from 2019 to 2026. This growth illustrates the increasing adoption of CNC technology among furniture manufacturers seeking to streamline operations and reduce production costs.

By automating the cutting, shaping, and finishing processes, CNC machines significantly minimize labor expenses while increasing production speed. Data from Statista indicates that companies utilizing CNC technology can produce up to 80% more furniture in the same time frame compared to manual methods. This efficiency not only lowers overhead costs but also allows manufacturers to respond quickly to market demands and customize products without incurring substantial extra costs. As the furniture market continues to evolve, the implementation of CNC machinery is set to play a crucial role in driving profitability and maintaining competitive advantage.

Future Trends: Innovations in CNC Technology and Their Impact on the Furniture Industry

The furniture industry is experiencing a transformative shift towards precision engineering, primarily driven by advancements in CNC technology. This innovative approach allows manufacturers to produce high-quality wooden products with unparalleled accuracy, thereby meeting the diverse demands of modern consumers. As companies adopt CNC machines, they enhance their operational efficiency and significantly reduce material waste, ultimately leading to greater sustainability within the sector.

Recent trends indicate that wood CNC machines are not only streamlining the production process but also enabling the customization of furniture designs. With these machines, artisans can easily create intricate designs and unique pieces tailored to individual customer preferences. This shift towards personalization, combined with the high level of precision offered by CNC technology, positions the furniture industry for robust market growth and sets a new standard for craftsmanship. As the integration of advanced CNC solutions continues, the potential for innovative furniture design and manufacturing is limitless, paving the way for a more dynamic and competitive marketplace.

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

| Dimension | Specification | Impact on Furniture Production | Future Trends |

|---|---|---|---|

| Cutting Accuracy | 0.01 mm precision | Reduced waste and materials costs | Enhanced automation leading to higher precision |

| Processing Speed | Up to 60% faster than traditional methods | Increased output and reduced production time | Integration with AI for real-time adjustments |

| Material Versatility | Compatible with various wood types | Ability to create diverse design elements | Advancements in multi-material capabilities |

| Customization Options | Personalized design capabilities | Meeting customer-specific requirements | Growth of on-demand furniture production |

| Sustainability | Efficient use of materials | Decreased environmental impact | Focus on eco-friendly manufacturing practices |

Related Posts

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping