- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

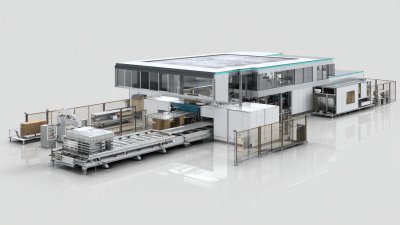

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

In the world of DIY projects, selecting the right tools can significantly impact the outcome and efficiency of your work. Among these essential tools, a sanding machine plays a crucial role in achieving a smooth and polished finish on various surfaces. According to a recent industry report by Market Research Future, the global sanding machine market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2027, reflecting the increasing demand for high-quality woodworking and refinishing tools. With a plethora of options available, it's vital to understand the features and types of sanding machines to make an informed choice that meets your project needs. Whether you are tackling a small craft or a larger renovation, the right sanding machine can enhance your efficiency and elevate the quality of your finished work.

Understanding Different Types of Sanding Machines: Characteristics and Applications

When choosing the perfect sanding machine for your DIY projects, understanding the various types available is crucial to achieving the best results. Among the most common types are belt sanders, orbital sanders, and detail sanders, each with their unique characteristics and applications. Belt sanders are ideal for large, flat surfaces and can remove material quickly, making them suitable for heavy-duty tasks. Meanwhile, orbital sanders provide a smoother finish and are versatile enough for both flat and curved surfaces, making them a favorite for general woodworking tasks.

Detail sanders, on the other hand, excel in tight spaces and intricate designs, allowing for precision in finishing work. Their unique shape helps to reach areas that larger sanders cannot, making them essential for detailed projects. With advancements in sanding technology, many machines now incorporate features that enhance user experience, such as dust collection systems that minimize cleanup and improve air quality. By selecting the right sanding machine based on the type of project and desired finish, DIY enthusiasts can ensure professional-quality results.

Key Factors to Consider When Choosing a Sanding Machine for Your DIY Needs

When selecting the perfect sanding machine for your DIY projects, several key factors stand out. First, consider the type of project you’ll be working on. According to the American Woodworking Association, different sanding machines serve varied purposes; for instance, orbital sanders are ideal for finishing work due to their random orbit motion, while belt sanders excel in removing material quickly for heavy-duty tasks. Knowing the right type of sander for your specific needs can significantly enhance your project's efficiency and outcome.

Another critical factor is the power and speed of the sanding machine. A recent report by Consumer Reports indicates that higher wattage tools tend to have more effective sanding capabilities, reducing time and effort during use. Additionally, adjustable speed settings allow for versatility across different materials—wood, metal, or plastics. The ability to control the speed can help you manage the risk of damaging finer surfaces, making it an essential feature for DIY enthusiasts looking to achieve professional results at home.

Comparing Sanding Machine Power Ratings: What You Need to Know for Efficiency

When selecting the perfect sanding machine for your DIY projects, understanding power ratings is crucial for achieving the efficiency you desire. Sanding machines typically range from light to heavy-duty classifications, and the power rating, usually measured in watts or amps, directly impacts their performance. Higher power ratings often translate to better efficiency, enabling the machine to handle more challenging tasks like sanding rough surfaces or working with dense materials. For instance, a 5-amp sander may be adequate for light jobs, while a 10-amp model is better suited for rigorous applications.

Additionally, it's important to consider the type of sanding machine you need in relation to its power rating. Random orbit sanders, belt sanders, and finishing sanders all have different power requirements based on their design and intended use. A random orbit sander generally provides versatility with a moderate power range, making it ideal for both finishing and initial sanding. Conversely, if your project demands heavy material removal, investing in a more powerful belt sander would be advantageous, as its higher power allows for faster and more efficient results. Understanding these nuances will help you make an informed decision, ensuring you choose a machine that maximizes productivity and suits your project's demands.

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

| Model Type | Power Rating (Watts) | Weight (lbs) | Dust Collection | Speed (RPM) | Price Range (USD) |

|---|---|---|---|---|---|

| Orbital Sander | 350 | 3.5 | Yes | 12,000 | $50 - $120 |

| Belt Sander | 750 | 6.5 | Yes | 15,000 | $80 - $200 |

| Detail Sander | 220 | 2.0 | No | 14,000 | $30 - $70 |

| Random Orbital Sander | 400 | 4.0 | Yes | 10,000 | $70 - $150 |

Best Practices for Maintenance: Prolonging the Life of Your Sanding Machine

Proper maintenance of your sanding machine is crucial for extending its lifespan and ensuring optimal performance. Regularly cleaning the machine after each use helps prevent the buildup of dust and debris that can lead to mechanical issues. Use a soft brush or compressed air to remove particles from the machine’s exterior and interior. Additionally, checking and replacing worn sanding pads or belts promptly will not only improve sanding efficiency but also protect the motor from unnecessary strain.

Lubrication is another key practice to keep your sanding machine in peak condition. Refer to the manufacturer's instructions for guidance on which parts require lubrication and the appropriate type of lubricant to use. Regularly inspecting electrical components and connections is also essential; loose wires or corroded connectors can lead to safety hazards or malfunctions. By following these best practices, you can significantly prolong the life of your sanding machine and enhance your DIY projects' productivity.

The Sanding Machine Performance Comparison

Expert Tips for Selecting the Right Sandpaper Grit for Your Project Type

When selecting the right sandpaper grit for your woodworking project, it’s crucial to understand how grit size impacts the finish of your work. Generally, sandpaper is available in grits ranging from coarse (40-60) to fine (120-220 and above). For initial sanding, a lower grit number helps remove material quickly and shape your project. However, as you refine your work, transitioning to a medium grit (80-100) is recommended to smooth out rough surfaces. For the final touches, using fine grit ensures a clean, polished finish, essential for showcasing the craftsmanship of your project.

Professional woodworkers emphasize the importance of matching the type of sandpaper to the material you’re working with. While standard aluminum oxide sandpaper is versatile and suitable for various wood surfaces, specialized options like silicon carbide are better for sanding softer materials or finishes. According to industry reports, using the correct grit not only improves the aesthetics of your work but can also save time and reduce material waste—up to 30% in some cases. This strategic approach in selecting sandpaper can significantly enhance your DIY results and elevate your woodworking projects to a professional level.

Related Posts

-

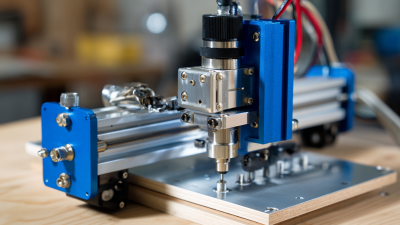

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques