- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

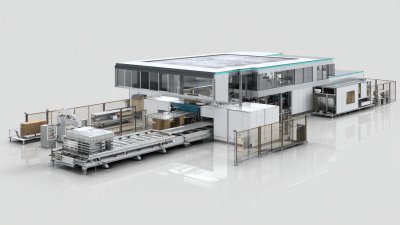

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

When it comes to DIY projects, selecting the right tools is essential for achieving professional results, and a sanding machine is no exception. According to a report by the Woodworking Machinery Industry Association, approximately 65% of amateur woodworkers agree that the quality of their sanding equipment significantly impacts the final outcome of their projects. Moreover, with the global market for power tools projected to reach $41 billion by 2025, understanding how to choose the best sanding machine tailored to your needs has never been more crucial.

Whether you're refinishing furniture or crafting intricate wooden pieces, selecting an appropriate sanding machine can enhance efficiency, improve surface finishes, and reduce preparation time, making this guide your ultimate resource for informed decision-making in your DIY endeavors.

Understanding the Different Types of Sanding Machines for DIY Projects

When selecting a sanding machine for your DIY projects, it’s essential to understand the various types available and their specific uses. Among the most popular options is the random orbital sander, renowned for its versatility and ability to deliver a smooth finish on wood surfaces. This type of sander operates in circular motions while simultaneously moving in an elliptical pattern, making it effective for tackling a variety of woodworking tasks, from furniture refinishing to surface preparation.

In addition to random orbital sanders, detail sanders are excellent for projects requiring precision. These compact machines are designed to reach tight corners and intricate details, ensuring every part of your project is beautifully finished. For more extensive tasks, belt sanders provide rapid material removal, making them ideal for larger surfaces. Understanding these different sanding machine types will enable you to choose the right tool tailored to your project needs, ultimately enhancing the quality and efficiency of your work.

Key Features to Look for in a Sanding Machine

When selecting a sanding machine for your DIY projects, several key features can significantly enhance your woodworking experience. First and foremost, consider the type of sanding machine you need. Orbital sanders offer versatility for various surfaces and are ideal for finishing jobs, while belt sanders are perfect for heavy material removal. The decision between these tools depends on the nature of your projects and your desired finish.

Another critical feature to evaluate is the sanding machine's power and speed control. A machine with adjustable speed settings allows you to customize the sanding process based on the material being worked on, ensuring optimal results. Additionally, look for ergonomic designs that provide comfort during extended use, as a comfortable grip and manageable weight can reduce fatigue and enhance precision.

Finally, check for dust collection systems that keep your workspace clean and decrease respiratory hazards, making the sanding process safer and more efficient.

How to Choose the Right Sanding Machine for Your Material

When selecting the right sanding machine for your DIY projects, it's essential to consider the type of material you'll be working with. Different materials require different approaches to achieve smooth surfaces without damaging the substrate. For example, if you’re working with softwoods like pine, a random orbital sander can effectively eliminate imperfections while being gentle enough to avoid gouging. On the other hand, when dealing with hardwoods, a more aggressive approach may be necessary. In such cases, a belt sander can remove material rapidly, although it requires a careful touch to prevent over-sanding.

In addition to the material, the size and scale of your projects are crucial factors to keep in mind. For larger surfaces, such as table tops or doors, a larger sander will speed up the process significantly, while a smaller hand sander is ideal for intricate work or tight corners. Moreover, consider the dust collection capabilities of the machine. A good dust collection system will not only keep your workspace clean but also improve your visibility and safety during sanding. Ultimately, by matching the sanding machine to both the material and the project size, you can maximize efficiency and achieve professional results in your DIY endeavors.

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

Tips for Maintaining Your Sanding Machine for Longevity

Maintaining your sanding machine is crucial for ensuring its longevity and optimal performance in your DIY projects. According to a recent report by the Machinery Maintenance Institute, properly maintained equipment can last up to 30% longer than neglected counterparts. Regularly checking and replacing sanding belts is essential; worn belts can not only hinder efficiency but also lead to surface damage on your projects. Aim to replace belts every 20-30 hours of use, and always use the correct grit for your specific application.

Additionally, keeping the sanding machine clean will prevent dust and debris from causing wear and tear on internal components. The American Sanding Association suggests that routine cleaning should occur after every use, and a thorough inspection should be done weekly to identify potential issues early on. Lubricating moving parts and ensuring that all screws and bolts are tight can further extend the life of your machine. By following these maintenance tips, you can ensure that your sanding machine remains a reliable tool for all your DIY endeavors.

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

| Sanding Machine Type | Best Uses | Power Source | Recommended Grit Sizes | Maintenance Tips |

|---|---|---|---|---|

| Belt Sander | Large flat surfaces, removing material quickly | Electric | 40-80 grit for aggressive sanding, 120-220 grit for finishing | Clean the belt regularly, check for alignment |

| Orbital Sander | Fine finishing, sanding intricate shapes | Electric | 80-120 grit for smoothing, 220 grit for polishing | Change sandpaper regularly, vacuum out dust |

| Detail Sander | Hard-to-reach areas, detailed work | Electric | 120-220 grit for detailed finishing | Use soft pads for even sanding, avoid excessive pressure |

| Disc Sander | Flat surfaces, trimming edges | Electric | 60-120 grit for removal, 220 grit for finishing | Ensure discs are tight, manage dust collection |

Safety Precautions When Using Sanding Machines in DIY Projects

When diving into DIY projects, the use of sanding machines can elevate the finish but comes with inherent risks. According to the U.S. Bureau of Labor Statistics, around 12,000 injuries related to woodworking machinery occur annually, emphasizing the need for strict safety precautions. Firstly, wearing appropriate personal protective equipment (PPE) such as safety goggles, dust masks, and hearing protection is crucial. The National Institute for Occupational Safety and Health (NIOSH) recommends a minimum N95 respirator when dealing with fine particulate matter created during sanding.

Moreover, maintaining a tidy workspace can significantly mitigate risks. A study published in the Journal of Safety Research found that 30% of workplace injuries stem from slips and falls due to cluttered environments. Ensuring that your sanding area is free of debris not only enhances your working efficiency but also reduces the chance of accidents. Furthermore, understanding your equipment is vital; always refer to the manufacturer's guidelines for proper usage, as improper handling can lead to severe injuries. By prioritizing safety and remaining mindful of best practices, DIY enthusiasts can enjoy their projects with confidence and protection.