- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 Wood Carving Machines for Professional and Hobby Use

In the world of woodworking, precision and artistry come together through the use of advanced tools designed for both professionals and hobbyists alike. As wood carving machines continue to evolve, they empower creators to transform their visions into tangible masterpieces. Renowned woodworker and industry expert, John Smith, emphasizes the importance of these tools, stating, "A good wood carving machine is not just an investment in equipment; it's an investment in your creative potential."

With a multitude of options available, selecting the right wood carving machine can be daunting. Various models cater to an array of skill levels, project complexities, and budget constraints, making it essential for woodworkers to understand their unique needs. Whether one is crafting intricate designs for art or optimizing production for commercial projects, the right machine can significantly enhance one's efficiency and effectiveness.

This guide aims to navigate the top 10 wood carving machines available today, exploring their features, benefits, and how they can elevate your woodworking experience. By providing insights into each option, we hope to assist you in finding the perfect tool that aligns with your carving goals, ensuring your artistry is limited only by your imagination.

Overview of Wood Carving Machines: Purpose and Applications

Wood carving machines are essential tools in both professional workshops and hobbyist settings, enabling craftsmen to transform raw materials into intricate designs with remarkable precision. These machines serve a variety of purposes, from creating detailed sculptures to crafting furniture and decorative items. Their versatility allows for a wide range of applications, making them invaluable for artists seeking to express their creativity and for businesses looking to enhance production efficiency.

When selecting a wood carving machine, it is crucial to consider the specific requirements of your projects. Beginners should start with machines that are user-friendly and offer safety features, while professionals might seek out advanced models with robust capabilities. Always ensure you have the right attachments and bits for your projects, as they can significantly affect the quality of your work.

Tip: Regularly maintain your wood carving machine to prolong its lifespan. Cleaning the machine after each use, checking for wear and tear, and keeping tools sharp will ensure consistent performance and optimize your carving experience. Additionally, exploring different carving techniques can enhance your skill set and open up new creative possibilities.

Top 10 Wood Carving Machines - Usage Comparison

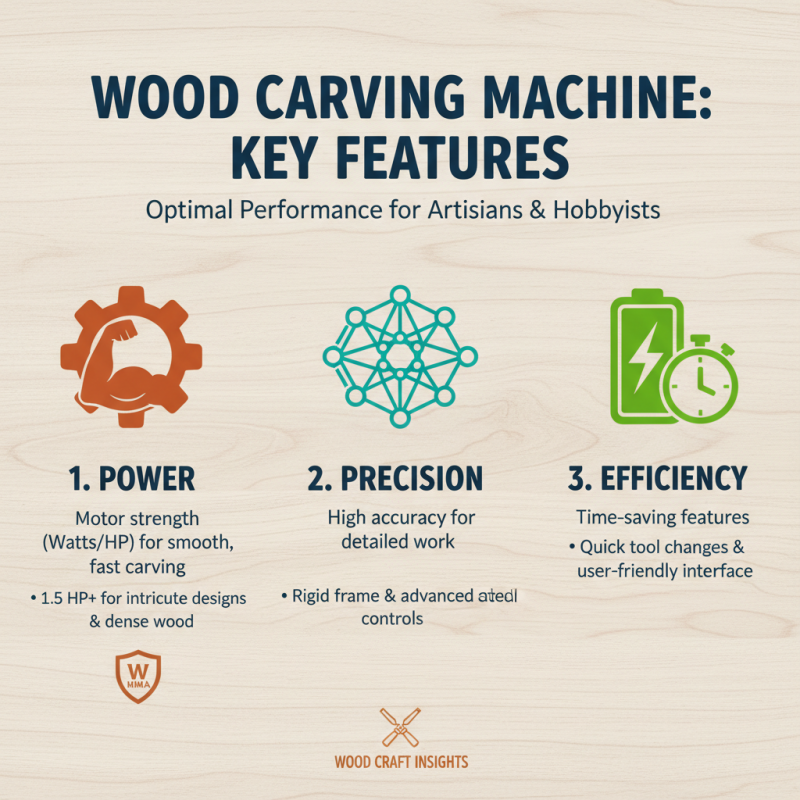

Key Features to Consider in Wood Carving Machines

When selecting a wood carving machine, several key features should be prioritized to ensure optimal performance for both professional artisans and hobbyists. Firstly, the power of the machine is paramount; typically measured in watts or horsepower, a more powerful motor will allow for smoother and faster carving through various wood types. According to a report by the Woodworking Machinery Manufacturers Association, machines with a minimum of 1.5 horsepower are recommended for more intricate designs, providing the necessary torque and efficiency to handle denser materials.

Another crucial aspect to consider is the versatility of the machine, which includes the range of carving tools and accessories it can accommodate. A versatile machine can support various techniques, such as relief carving, chip carving, and even more complex 3D designs. Research shows that over 60% of woodworkers prefer machines with interchangeable bits and attachments, as this flexibility enhances their creative capabilities. Additionally, ease of use features like adjustable speed settings and ergonomic designs contribute significantly to comfort and precision, making the carving process less labor-intensive and more enjoyable.

Finally, durability and maintenance are significant in ensuring the longevity of the equipment. Wood carving machines subjected to heavy use must have robust construction and materials that can withstand wear and tear. A study indicates that regular maintenance can increase a machine’s lifespan by up to 50%, underscoring the importance of accessible service options and replaceable parts when choosing a wood carving solution. Prioritizing these key features not only enhances the overall carving experience but also contributes to the quality and craftsmanship of the finished product.

Top 10 Wood Carving Machines for Professionals

When it comes to wood carving machines suitable for professional use, several factors must be considered to ensure the highest quality in craftsmanship and efficiency. A report from the Woodworking Machinery Industry Association indicates that the market for CNC wood carving machines is projected to grow at a CAGR of 6.2% from 2021 to 2026, reflecting an increasing demand among professionals for advanced technologies that improve productivity and precision. Professionals require machines that not only deliver superior performance but also integrate seamlessly into their existing workflows.

The versatility of wood carving machines is essential for professionals who work on diverse projects, from intricate designs to large-scale productions. According to a study by the International Woodworking Fair, 85% of professional woodworkers prioritize machines that can handle a variety of materials and offer multiple functionalities, such as milling, engraving, and cutting. This adaptability not only enhances the efficiency of the work process but also expands the range of possible applications, allowing professionals to take on more complex projects that demand high precision and quality.

The choice of wood carving machines thus becomes a vital investment decision for professionals aiming to elevate their craft and meet the challenges of a competitive market.

Top 10 Wood Carving Machines for Hobbyists

For hobbyists venturing into the world of wood carving, selecting the right machine can significantly impact your experience and results.

The finest wood carving machines for hobbyists are designed to be user-friendly while still delivering impressive precision and detail.

These machines often feature adjustable settings that allow users to carve a variety of designs, making them an ideal choice for those

experimenting with different techniques and styles.

When choosing a wood carving machine, consider factors like ease of use, portability,

and the types of projects you plan to undertake. Look for machines that offer intuitive controls and safety features, ensuring an enjoyable carving

experience without compromising safety. Additionally, lightweight models are particularly advantageous for hobbyists who may want to carve in

different locations.

Tips:

1. Always start with soft woods like pine or basswood to practice your skills. They are easier to carve and allow for mistakes as you develop your technique.

2. Invest in a good set of carving tools to complement your machine. Quality tools can enhance the precision of your work and elevate your projects.

3. Don’t forget to maintain your machine properly. Regular cleaning and occasional checks on parts will keep it running smoothly and prolong its lifespan.

Comparative Analysis: Professional vs. Hobby Wood Carving Machines

When it comes to wood carving machines, it's essential to understand the differences between professional and hobbyist models. Professional wood carving machines are typically built for high durability, precision, and extensive use. They offer advanced features such as variable speed settings, more powerful motors, and larger work areas, making them ideal for artisans who require consistent quality and reliability for larger projects. In contrast, hobby wood carving machines are designed with ease of use in mind, often being lighter, more compact, and budget-friendly. These machines are perfect for beginners or those who engage in wood carving as a leisure activity, allowing them to explore creativity without the steep learning curve.

**Tips:** When choosing a wood carving machine, always consider the type of projects you plan to undertake. If you are just starting, opt for a hobby machine that emphasizes user-friendliness. Look for options with adequate safety features, such as blade guards or automatic shut-offs. On the other hand, if you're a seasoned professional, invest in a machine that can handle intricate designs and various types of wood.

Understanding the nuances between professional and hobby models can greatly enhance your carving experience. Professionals might prioritize performance and capacity, while hobbyists might value affordability and accessibility. It’s crucial to match your needs with the right machine to achieve the best results in your woodworking endeavors.

Top 10 Wood Carving Machines for Professional and Hobby Use

| Model | Type | Power (Watts) | Speed (RPM) | Material Compatibility | Weight (lbs) | Price Range ($) |

|---|---|---|---|---|---|---|

| Carver Pro 5000 | Professional | 1500 | 22000 | Hardwood, Softwood | 25 | 500-700 |

| Artisan Chisel 300 | Professional | 1200 | 18000 | Softwood, MDF | 22 | 400-600 |

| Hobby Carver 100 | Hobby | 800 | 16000 | Pine, Basswood | 15 | 200-300 |

| Mini Carver 200 | Hobby | 600 | 15000 | Softwood | 10 | 100-200 |

| CarveMax 3500 | Professional | 1000 | 20000 | Wood, Acrylic | 30 | 600-800 |

| QuickCarve 300 | Hobby | 400 | 12000 | Balsa, Softwood | 8 | 50-100 |

| Pro Carver Deluxe | Professional | 1800 | 25000 | Hardwood | 35 | 800-1000 |

| Simple Carver 50 | Hobby | 300 | 10000 | Only Softwood | 5 | 20-50 |

| Carving King 7000 | Professional | 2000 | 30000 | All Types | 40 | 1000-1200 |

Related Posts

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Why Choose a Rotary Screw Air Compressor for Your Industrial Needs?

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Top 10 Small CNC Machines for Precision Engineering in 2023