- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

In the rapidly evolving landscape of industrial machinery, the demand for efficient and reliable equipment is paramount. Among various options, the rotary screw air compressor has emerged as a leader, accounting for over 70% of the industrial air compressor market. According to a recent report by Research and Markets, the global air compressor market is projected to exceed $44 billion by 2025, with rotary screw compressors being the preferred choice for numerous applications due to their energy efficiency and low maintenance costs.

Manufacturers are increasingly recognizing the advantages of rotary screw air compressors, which operate using a continuous flow of compressed air, resulting in minimal downtime and reduced operational costs. A study from the Compressed Air and Gas Institute highlights that transitioning from reciprocating to rotary screw compressors can lead to energy savings of up to 30%, making them an attractive investment for businesses aiming to improve their bottom line and enhance performance.

As we prepare to explore the top five rotary screw air compressors for 2025, it's essential to consider factors such as reliability, energy efficiency, and advanced technological features. These compressors not only offer superior performance but also play a crucial role in achieving sustainability and operational excellence in various industries.

Top 5 Rotary Screw Air Compressors to Boost Industrial Efficiency in 2025

As industries strive for enhanced efficiency in 2025, selecting the right rotary screw air compressor is crucial. Research shows that rotary screw compressors can improve energy efficiency by 10-20% compared to their piston counterparts, making them an essential choice for manufacturers aiming to reduce operational costs. The latest models offer advanced features such as variable speed drives (VSD) and integrated air treatment systems, further optimizing performance and energy consumption.

**Tips:** When choosing a rotary screw compressor, consider the system's duty cycle and required airflow. It’s beneficial to conduct an air audit to accurately gauge your production needs. Additionally, integrating smart technology into your compressor setup can lead to predictive maintenance, reducing downtime by up to 30%, based on industry reports.

Innovative designs in the top 5 rotary screw air compressors of 2025 focus on cutting-edge technology that not only enhances performance but also extends the lifespan of the equipment. With features such as improved cooling systems and more efficient rotors, these compressors ensure that industrial facilities can operate at peak efficiency while minimizing energy wastage.

**Tips:** Regular maintenance schedules and remote monitoring tools can significantly increase the longevity of your air compressor, allowing for better resource management and saving on future repair costs.

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

This chart displays the performance metrics of the top 5 rotary screw air compressors for 2025 based on their efficiency ratings, noise levels, and power consumption. These compressors are vital for enhancing industrial efficiency.

Key Features to Look for in High-Performance Rotary Screw Compressors

When selecting a high-performance rotary screw air compressor, several key features should be prioritized to ensure optimal efficiency and reliability. One of the most critical aspects is the compressor's efficiency rating, typically indicated by its specific power consumption, measured in kW per cfm. According to a recent report by the Compressed Air and Gas Institute (CAGI), high-performance models achieve efficiencies as low as 5-9 kW per 100 cfm, which significantly reduces operational costs over time.

Another vital feature to consider is the system's control and monitoring capabilities. Advanced rotary screw compressors are now equipped with smart controls that allow for real-time performance tracking, temperature monitoring, and automatic adjustments based on demand. The 2021 World Energy Outlook estimated that implementing such smart technologies can lead to energy savings of up to 30% in industrial applications. Additionally, noise levels are also an important factor; selecting compressors operating at sound levels below 75 dBA can create a more comfortable working environment, making them suitable for diverse applications without compromising performance.

Lastly, durability and maintenance requirements are essential. Models utilizing high-quality materials and innovative designs, such as integrated oil filtration systems, significantly reduce downtime and extend service intervals. According to a report from the International Energy Agency, well-maintained rotary screw compressors can operate efficiently for over 100,000 hours, highlighting the importance of choosing equipment designed for longevity in demanding environments.

Maximizing Energy Savings with Advanced Rotary Screw Air Compressors

As industries increasingly focus on energy efficiency, rotary screw air compressors have emerged as a crucial component in achieving significant savings. According to a recent report by the Compressed Air and Gas Institute (CAGI), these systems can operate at up to 75% efficiency, which is a marked improvement over older models. By employing advanced technologies such as variable speed drive and integrated controls, modern rotary screw compressors enhance performance while minimizing energy consumption.

Investing in high-quality rotary screw compressors can yield substantial cost savings over time. The U.S. Department of Energy states that compressed air systems account for nearly 10% of the total industrial energy use, making the optimization of these systems vital. Recent advancements in design and control features allow for better load matching and reduced energy losses, contributing to overall operational efficiencies. As businesses look to meet stringent sustainability targets, adopting these advanced systems not only improves reliability but also aligns with the goals of reducing their carbon footprint.

Maintenance Tips for Prolonging the Life of Your Rotary Screw Compressor

To ensure longevity and optimal performance of your rotary screw air compressor, regular maintenance is crucial. Start with routine inspections to check for any signs of wear or damage. Regularly replace the oil and air filters, as clean filters promote better airflow and reduce the workload on the compressor. Monitoring the oil levels and ensuring they are within the manufacturer’s recommended range can prevent unnecessary strain and overheating.

Additionally, pay attention to the cooling system. Ensure that the cooling fins and filters are clean and free from debris, as efficient cooling is vital for preventing overheating during operation. Scheduled maintenance checks by a professional can also identify potential issues before they escalate. This proactive approach minimizes downtime and enhances the compressor's efficiency, ultimately prolonging its lifespan.

By adhering to these maintenance tips, operators can ensure their rotary screw compressors remain reliable and efficient for years to come.

Comparative Analysis: Leading Rotary Screw Air Compressors of 2025

As we advance into 2025, the market for rotary screw air compressors showcases significant innovations that enhance performance, efficiency, and usability. A comparative analysis of the leading models reveals distinct advancements in energy-saving technologies and noise reduction features. One standout model utilizes a new variable speed drive system, which optimizes power consumption based on actual air demand, resulting in substantial energy savings without compromising output.

Moreover, the latest compressors are designed with advanced control systems that facilitate real-time monitoring and diagnostics. These systems not only enhance operational efficiency but also contribute to predictive maintenance, minimizing downtime and maintenance costs.

When assessing the top contenders, features such as compact design, ease of installation, and superior build quality are crucial for industries that rely on consistent air supply. The amalgamation of these cutting-edge technologies positions these rotary screw air compressors as indispensable tools for various applications, ensuring businesses can maintain optimal performance levels in an increasingly competitive environment.

Related Posts

-

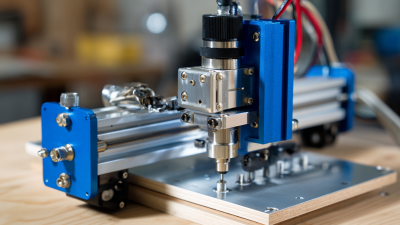

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

-

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques