- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 C and C Machine Types You Should Know about?

In the world of manufacturing, the importance of C and C machines cannot be overstated. According to a report by the Manufacturing Technology Association, the C and C machine sector has witnessed a remarkable growth rate of 8% annually. This growth highlights the increasing demand for precision machinery across different industries. Expert James Thornfield, a leading voice in CNC technology, states, “C and C machines are revolutionizing how we approach production efficiency.”

From automotive to aerospace, C and C machines play a critical role in shaping components with minimal human intervention. The diversity of machine types available can be overwhelming, yet understanding these types is essential for maximizing manufacturing potential. Companies that utilize advanced C and C technology report improved accuracy and reduced waste, leading to higher profit margins.

Still, not all manufacturers have embraced these innovations. Some struggle with outdated equipment and lack of training. This gap can hinder competitiveness in a rapidly evolving market. As we explore the top 10 C and C machine types, it’s crucial to reflect on both the advantages and the challenges ahead.

Top 10 CNC Machine Types in the Manufacturing Industry

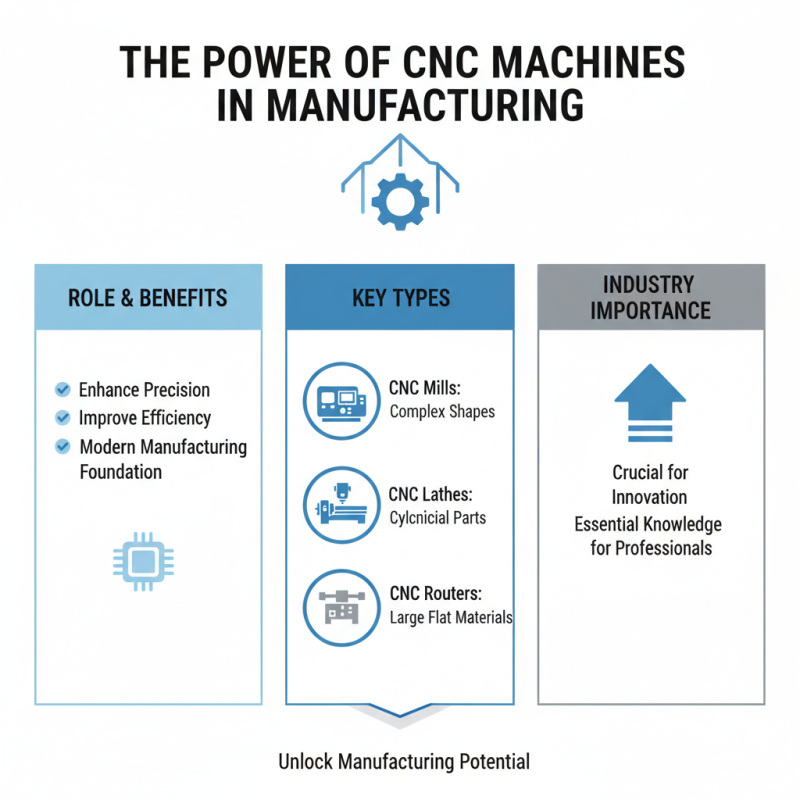

CNC machines play a crucial role in modern manufacturing. They enhance precision and efficiency. Understanding different types of CNC machines is vital for anyone in the industry.

CNC milling machines are widely used. They cut materials into specific shapes. These machines move the workpiece and tools along multiple axes. This allows for intricate designs. But, the setup can be complicated. It requires skill and experience to program correctly.

Similarly, CNC lathes shape materials by rotating them. They provide excellent surface finish and accuracy. However, improper setup can lead to wasted materials. Operators must pay attention to intricate details. We also have CNC routers, ideal for woodworking. They can cut, carve, and engrave. Yet, they can be challenging to adjust for different materials. Familiarity with these machines is essential for optimizing production processes.

Understanding the Basics of CNC Machines and Their Functions

CNC machines, or Computer Numerical Control machines, are essential in manufacturing today. These automated tools perform precise movements based on programmed instructions. A recent industry report indicated that the global CNC machine market is expected to reach $90 billion by 2026. This reflects a growing reliance on technology for enhanced productivity and precision.

Understanding CNC basics is crucial for efficient operation. Most CNC machines can transform raw materials into finished products. They do this by interpreting G-code, a language that tells the machine how to move. There are various types, including milling, turning, and plasma cutting machines. Each type serves specific purposes and differs in complexity. For operators, mastering these functions is vital for success, but training can be inconsistent. Many workers express frustration over the learning curve.

Moreover, despite advances, some challenges remain. Maintenance issues can disrupt production. An estimated 20% of CNC machine downtime is due to mechanical failures. Operators often feel unprepared to handle such problems. This gap in training highlights the need for more comprehensive education in CNC technology. Understanding these factors can help improve efficiency and reduce waste in various manufacturing sectors.

Key Features and Specifications of Each CNC Machine Type

CNC machines come in various types, each designed for specific tasks. These machines automate processes, enhancing efficiency and precision. The most common types include CNC milling, CNC turning, and CNC plasma cutting. Each machine type has unique features and specifications. For instance, milling machines rely on rotating cutting tools. Turning machines, on the other hand, use a rotating workpiece, allowing for cylindrical shapes. Plasma cutters utilize electrically conductive gas to cut through metals, providing clean and precise edges.

When choosing a CNC machine, consider factors such as material compatibility and size. Some machines excel at heavy-duty tasks, while others are tailored for detailed work. Look for machines with robust control systems. Capability in automation can significantly reduce manual errors. Monitoring and maintenance are critical as well. In this evolving technology landscape, staying updated is essential. Some newer machines come with advanced software integration, but they may require a learning curve.

Understanding these specifications enables better decision-making. A thorough analysis of each machine's strengths and weaknesses is necessary. While the options are vast, each choice should align with your specific needs and workflow. Collecting feedback from users can also highlight practical insights. Engaging in a trial or pilot project helps clarify the actual performance before committing.

Industry Applications: Where Different CNC Machines Excel

CNC machines are essential in many industries. Different types shine in specific applications. For instance, CNC milling machines excel in producing intricate parts. They create complex shapes with precision and speed. Aerospace and automotive sectors rely heavily on this technology. These industries require tight tolerances and specific materials.

On the other hand, CNC lathes are favored for cylindrical designs. They turn material around a stationary tool, shaping it effectively. This is crucial in manufacturing shafts and gears. Various industries value this precision. However, mastering these machines takes time. Mistakes can lead to material waste and increased costs.

Laser cutters, another type, are exceptional for cutting hard materials. They offer efficiency and accuracy. Industrial sectors use them for metal, plastic, and wood. Yet, laser technology can be unforgiving. A miscalculated setting can ruin an entire batch. Thus, operators need proper training and experience. Embracing these challenges can lead to remarkable outcomes.

Top 10 CNC Machine Types and Their Industry Applications

Trends in CNC Technology: Innovations and Future Outlook

CNC technology is evolving rapidly. Innovations are creating smarter, more efficient machines. Automation is now key in CNC machining. Machines with artificial intelligence are starting to learn from operations. They analyze data and optimize processes in real-time. This helps reduce waste and improve precision.

As manufacturers adopt these technologies, there are challenges. Not all workers are trained to handle advanced systems. Skill gaps can cause disruptions in production. It's vital for companies to invest in training. Worker adaptation is crucial for maximizing technology benefits.

Sustainability is another focus. CNC machines are becoming more energy-efficient. Innovations lead to reduced energy consumption and lower emissions. However, the industry must remain vigilant. Balancing innovation with environmental responsibility requires ongoing effort and commitment. The future lies in finding this balance.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

How to Optimize C and C Machine Operations for Maximum Efficiency?

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

-

The Best CNC Mill Types for Your Machining Needs?