- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

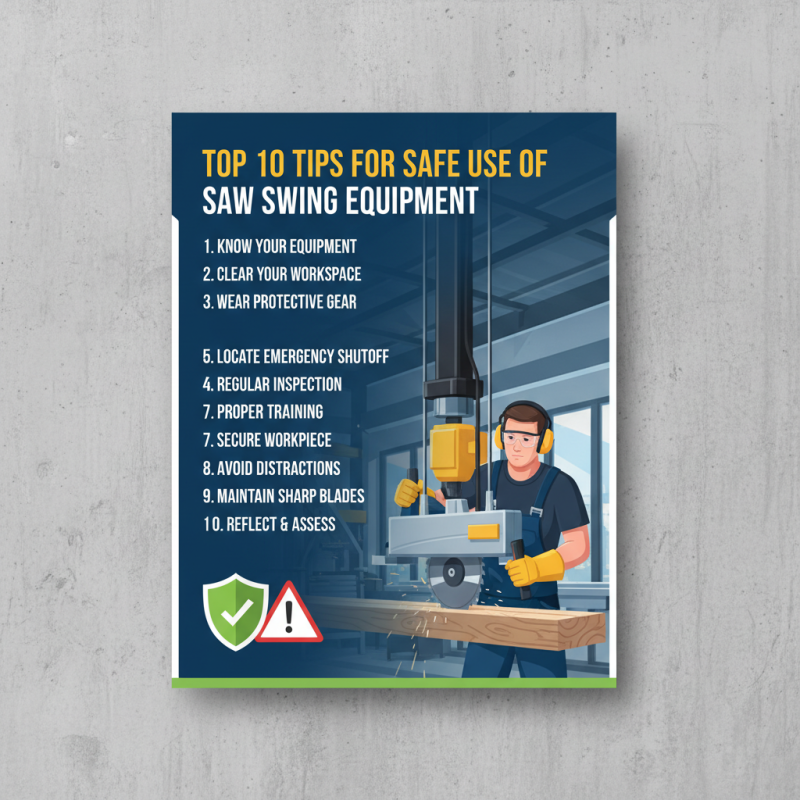

Top 10 Tips for Safe Use of Saw Swing Equipment?

When working with saw-swing equipment, safety must be a priority. This powerful machinery can be a double-edged sword. Proper usage ensures efficiency, but mistakes can lead to serious accidents. Understanding how to handle saw-swing tools effectively is crucial.

It’s essential to know the equipment's features and potential risks. Know your workspace. Clutter can lead to accidents and limit movement. Wearing protective gear is necessary. Eye protection and gloves can prevent injuries during operation. Familiarize yourself with the emergency shutoff. Misjudgments can happen, and quick responses are vital.

Engaging with saw-swing equipment can be rewarding, but it demands respect and responsibility. Reflect on past experiences. Have you overlooked any safety measures? Continuous self-assessment improves safety practices. Let’s delve into ten tips that promote safe and effective use of saw-swing machinery.

Understanding Saw Swing Equipment and Its Uses

Saw swing equipment plays a crucial role in various industries. It is essential for cutting, shaping, and finishing materials. This equipment often includes swing saws, which can be found in factories and construction sites. According to industry reports, improper use accounts for a significant number of accidents, highlighting the need for safety awareness.

To ensure safe use, it’s vital to understand the equipment. Users should regularly inspect the saw for any wear or damage. A faulty saw can lead to serious injuries. Proper training on equipment usage is equally important. Many reports suggest that about 30% of accidents stem from untrained users.

Implementing safety tips can mitigate risks. Always wear appropriate protective gear. This includes gloves, goggles, and ear protection. Stay focused while operating the saw. Distractions can be dangerous. Finally, maintain a clean workspace. A cluttered area increases the chances of accidents. Observing these practices can significantly improve safety when using saw swing equipment.

Essential Personal Protective Equipment for Safe Operation

When operating saw swing equipment, using personal protective equipment (PPE) is vital. The U.S. Bureau of Labor Statistics reports that injuries related to saw equipment account for nearly 20% of workplace accidents. This statistic underscores the importance of wearing protective gear to minimize risks.

Essential PPE includes safety goggles to protect the eyes from debris. Hearing protection is crucial too; saws can exceed 100 decibels, which can cause hearing loss. Thick gloves should be worn to protect hands from sharp edges, reducing the likelihood of cuts or lacerations. Steel-toed boots are another necessity. They shield feet from falling objects.

One aspect often overlooked is the comfort of PPE. Uncomfortable gear can hinder proper movement, leading to accidental injuries. Additionally, workers sometimes forget to wear helmets, exposing themselves to serious head injuries. Regular training on the importance of PPE can help bridge this gap. While PPE greatly improves safety, it is only effective if used correctly and consistently.

Top 10 Tips for Safe Use of Saw Swing Equipment

| Tip Number | Safety Tip | Essential PPE |

|---|---|---|

| 1 | Always wear safety goggles to protect eyes. | Safety Goggles |

| 2 | Use ear protection to reduce noise exposure. | Earplugs / Earmuffs |

| 3 | Wear a dust mask to avoid inhaling sawdust. | Dust Mask |

| 4 | Ensure you are wearing cut-resistant gloves. | Cut-Resistant Gloves |

| 5 | Maintain a clean and clutter-free workspace. | N/A |

| 6 | Check equipment for damage before use. | N/A |

| 7 | Use push sticks for controlling materials. | Push Stick |

| 8 | Do not wear loose clothing while operating. | N/A |

| 9 | Follow all manufacturer instructions carefully. | N/A |

| 10 | Be aware of your surroundings and potential hazards. | N/A |

Pre-Operational Checks and Maintenance Procedures

Pre-operational checks are essential for safe use of saw swing equipment. Examine the equipment for any visible wear and tear. Look for cracks, loose parts, or rust. The electrical components should also be inspected for frayed wires or exposed connections. Test the emergency stop function to ensure it works correctly. A checklist can help you remember these important steps.

Maintenance procedures play a vital role in equipment safety. Regularly lubricate moving parts to prevent friction and overheating. Keep blades sharp and clean to ensure efficient cutting. Dust and debris can accumulate, leading to accidents. Create a routine maintenance schedule to keep everything in check. It's important to document every inspection and maintenance task performed. This ensures accountability and helps identify recurring issues. Sometimes, we overlook minor details, thinking they are unimportant, but they can lead to larger problems later on.

Safe Operating Procedures and Techniques

Operating saw swing equipment safely is critical for preventing accidents and injuries. According to the Occupational Safety and Health Administration (OSHA), improper use of equipment accounts for nearly 40% of workplace injuries in the construction industry. It is vital to follow established operating procedures and techniques to minimize risks.

Before starting any operation, ensure that you perform a thorough inspection of the saw. Check the blade, guards, and safety features. Keep your workspace clean and clutter-free to avoid distractions. Always wear appropriate personal protective equipment (PPE), such as goggles and gloves. A study by the National Institute for Occupational Safety and Health (NIOSH) highlighted that 70% of accidents could have been avoided through proper safety protocols.

During operation, maintain a firm and stable stance. Avoid reaching over moving parts. Communication with team members is essential. Consider using clear signals or flags to indicate when the saw is in operation. This practice minimizes the chance of unexpected interruptions. Reflecting on past incidents can help identify areas where safety practices may lapse. Continuous training and adherence to safety standards are crucial for a sustainable work environment.

Top 10 Tips for Safe Use of Saw Swing Equipment

This chart illustrates the importance of various safety tips when using saw swing equipment. Each tip highlights a critical aspect of operating saws safely to minimize the risk of injuries.

Emergency Response and First Aid Measures for Accidents

Saw swing equipment can be dangerous. Accidents happen. Understanding emergency response and first aid is crucial for safety. According to the U.S. Bureau of Labor Statistics, there were over 5,000 incidents related to cutting equipment last year. In these situations, swift action can save lives.

First, assess the injury. Is there heavy bleeding? Control bleeding with a clean cloth. Apply pressure. If the wound is severe, keep the affected area elevated. Call for help immediately. Knowledge of CPR is essential. In cases of unconsciousness, check for breathing. If absent, start CPR right away. Basic training can make a difference.

Keep a well-stocked first aid kit nearby. It should include antiseptic wipes, bandages, and gloves. Regularly check that supplies are not expired. A study by the National Safety Council shows that many accidents could have been mitigated with proper first aid response. We often overlook ongoing training and awareness. Remember, preparation can make all the difference in an emergency.