- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

10 Essential Tips for Choosing the Right CNC Router for Your Projects

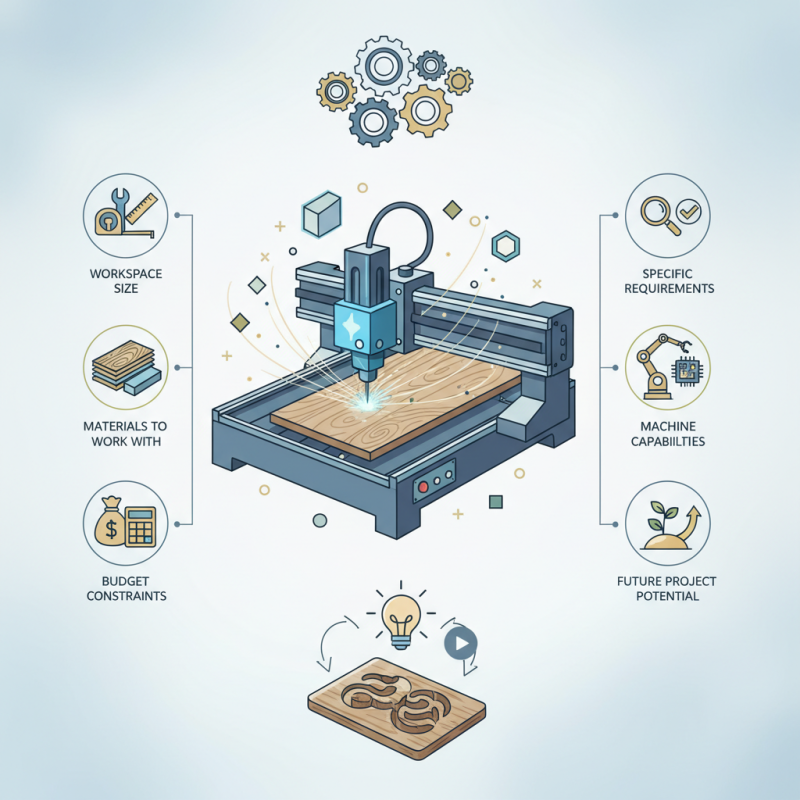

Choosing the right CNC router for your projects can seem daunting, especially with the multitude of options available in the market today. Industry expert John Smith, a renowned CNC technology consultant, affirms, "The perfect CNC router for your needs hinges on understanding your specific requirements and the capabilities of the machine." This insight is particularly valuable as it emphasizes the importance of aligning your project's demands with the features of the CNC router you intend to select.

Whether you're a hobbyist embarking on your first woodworking project or a seasoned professional aiming to enhance your production efficiency, understanding key factors such as the size of the workspace, the materials you will be working with, and budget constraints is crucial. As the CNC router technology evolves, it's essential to consider not only the current capabilities but also the potential for future projects. By taking a thoughtful approach to this selection process, you can ensure that your investment in a CNC router pays off, allowing you to create high-quality, precise work with relative ease.

Understanding CNC Router Types and Their Applications

When selecting the right CNC router for your projects, it's crucial to understand the various types of CNC routers available and their specific applications. CNC routers can be broadly categorized into wood routers, metal routers, and composite routers.

Wood routers are ideal for crafting intricate designs in hardwood, softwood, and plywood. These machines typically feature high-speed spindle motors that enable them to cut, carve, and engrave complex shapes with precision. They are commonly used in woodworking shops for furniture making, cabinetry, and decorative trimming.

Metal routers, on the other hand, are designed to cut through tougher materials like aluminum and steel. These routers often have sturdier frames and higher torque capabilities to withstand the demands of metalworking. They are essential for industries like manufacturing and prototyping, where precision and durability are vital.

Composite routers are specialized for materials such as fiberglass and carbon fiber, often used in aerospace and automotive applications. By understanding these types of CNC routers and their applications, you can make a more informed decision tailored to your specific project needs.

Key Factors to Consider When Assessing CNC Router Specifications

When selecting the right CNC router for your projects, understanding the specifications is crucial. Key factors to consider include cutting area, spindle speed, and precision capabilities. According to the Association for Manufacturing Technology (AMT), CNC routers with a minimum cutting area of 24" x 48" are widely preferred for hobbyist and small industrial applications, allowing for versatile project options without compromising on material size.

Another critical specification is spindle speed, which significantly affects cutting efficiency and material compatibility. A router with variable spindle speeds ranging from 12,000 to 24,000 RPM offers enhanced flexibility, enabling both rapid and detailed cutting finishes. Industry reports indicate that improved spindle speed leads to a reduction in machining time by up to 30%, ultimately increasing productivity.

Tips for selecting the right CNC router include assessing your specific project requirements before making a purchase. Determine the materials you will work with and ensure that the machine’s specifications align with those needs. Additionally, pay attention to the router's precision ratings; many advanced models offer tolerances as tight as ±0.001 inches, crucial for detailed designs. Finally, consider the machine's expandability; a router that accommodates additional accessories can adapt to your growing project demands over time.

Evaluating Size and Workspace Requirements for Your Projects

When embarking on the journey of selecting a CNC router, examining your size and workspace requirements is crucial. The dimensions of your workspace will significantly impact your choice, as it determines which CNC router can comfortably fit and operate efficiently. For smaller projects, a compact router might suffice, but larger ventures may necessitate a machine with an extended work area. It’s essential to measure your available space and consider not just the router itself, but also the necessary clearance for operation and maintenance.

One tip for evaluating size requirements is to consider the maximum dimensions of the materials you'll be working with. Always select a CNC router that can handle larger stock than the size of your finished projects. This will give you the flexibility needed for various designs and adjustments. Additionally, think about future projects; if you plan to expand your capabilities, opting for a larger machine may serve you better in the long run.

Another important aspect is the workspace environment. Ensure you have adequate ventilation and a clean area to prevent dust accumulation and enhance the lifespan of your router. For effective operation, it’s also wise to assess the flooring; a sturdy, level surface is necessary to support the weight and vibrations of a CNC router. By considering these factors, you can select a CNC router that fits seamlessly into your workspace and meets all your project demands.

10 Essential Tips for Choosing the Right CNC Router for Your Projects

This chart illustrates different size requirements for CNC routers suited for various project types, helping you evaluate which dimensions align with your workspace and project needs.

Selecting the Right Cutting Tools and Accessories for CNC Routers

When selecting the right cutting tools and accessories for CNC routers, it's crucial to consider the material you will be working with. Different materials, such as wood, plastic, and metal, require specific types of bits and tools to achieve optimal results. For example, spiral upcut bits are ideal for cutting softer woods, while downcut bits are better for plywood and composite materials, as they help prevent splintering. Additionally, solid carbide bits offer longevity and precision for harder materials, making them invaluable in a professional setting.

Accessories also play a critical role in maximizing the efficiency of your CNC router. A high-quality dust collection system is essential to maintain a clean workspace and prolong the life of your tools. Moreover, clamping systems and jigs ensure that materials are held securely in place during the cutting process, reducing the risk of errors. Lastly, investing in a reliable software package allows you to optimize cutting paths and speeds, further enhancing the accuracy of your CNC projects. By thoughtfully selecting tools and accessories, you can significantly improve the quality of your work and streamline your workflow.

10 Essential Tips for Choosing the Right CNC Router for Your Projects

| Tip Number | Tip Description | Important Factors | Recommended Features |

|---|---|---|---|

| 1 | Determine Your Project Requirements | Material type, size, complexity | Cutting area, spindle speed |

| 2 | Consider the Type of CNC Router | Router type (desktop, industrial) | Rigidity, precision |

| 3 | Assess Software Compatibility | Support for CAD/CAM software | User-friendly interface |

| 4 | Review Build Quality and Durability | Frame material, components | Steel or aluminum construction |

| 5 | Evaluate Customer Support and Warranty | Response time, availability | Comprehensive warranty options |

| 6 | Check for Additional Features | Automatic tool changers, dust collectors | Integrated controls, user settings |

| 7 | Identify Cutting Tools and Accessories | Router bits, collets | Various sizes and types |

| 8 | Assess the Price Range | Budget limitations | Value for features provided |

| 9 | Seek Feedback and Reviews | User experiences | Ratings and testimonials |

| 10 | Plan for Future Upgrades | Scalability | Compatibility with future tools |

Budgeting and Cost Considerations for CNC Router Purchase Options

When considering the purchase of a CNC router, budgeting plays a crucial role in making the right choice for your projects. The initial cost of the machine is often the most significant factor, but it’s essential to account for additional expenses that may arise. This includes purchasing software, tools, and any necessary accessories to optimize your machine's performance. Taking time to create a comprehensive budget will ensure that you prepare for both the direct costs and the potential hidden costs associated with your CNC router.

It’s also vital to evaluate the long-term expenses related to maintenance and operation. Different CNC routers have varying levels of energy efficiency and require different maintenance schedules, impacting ongoing costs. Additionally, consider the availability and price of replacement parts and consumables, as these can significantly affect your overall budget. By understanding both the initial investment and the expected long-term costs, you can make a more informed decision that aligns with your financial capabilities and project needs.

Related Posts

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

10 Essential Tips for Maximizing Efficiency with Your CNC Mill

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry