- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

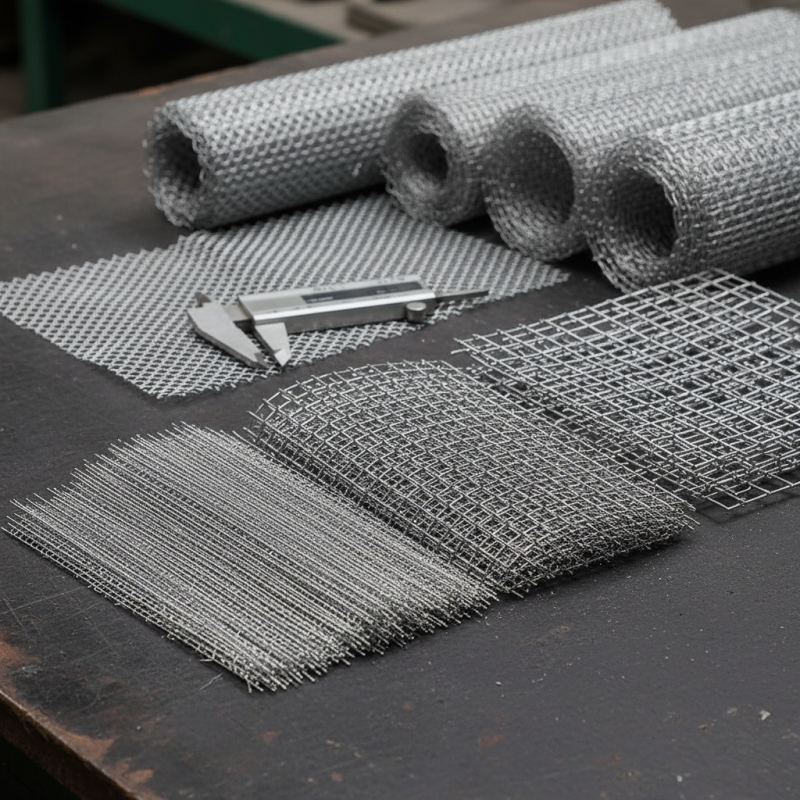

Ultimate Tips for Choosing Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be challenging. With various options available, it’s crucial to understand what suits your needs best. Stainless steel woven wire mesh offers durability and versatility for numerous applications.

Consider the type of stainless steel used. Different grades can impact longevity and strength. Think about the mesh size as well. A finer mesh provides better filtration, while a coarser one enhances airflow.

It’s important to reflect on how these choices align with your specific projects. Will the mesh withstand environmental factors? Can it accommodate the intended load? These questions are essential for making a sound decision. Understanding the details ensures your investment is worthwhile, minimizing regrets later on.

Understanding the Composition of Stainless Steel for Wire Mesh

When selecting stainless steel woven wire mesh, understanding its composition is crucial. Stainless steel typically consists of iron, chromium, nickel, and other elements. Chromium, usually around 10.5% or more, provides the corrosion resistance that stainless steel is known for. Reports suggest that over 70% of stainless steel is made from recycled materials, enhancing environmental sustainability.

The nickel content, often between 8% and 12%, improves the metal's ductility and strength. However, high nickel prices can impact overall costs. Data from industry analyses indicate that the global demand for stainless steel is projected to grow by over 3% annually. This demand emphasizes the importance of choosing the right type based on specific needs.

Not all stainless steel is the same. Variations exist, depending on alloying agents and processing. Some compositions may not perform well in all environments, leading to potential failures. Understanding the balance between cost and quality is vital. The selection process requires careful consideration and evaluation of performance in real-world applications.

Ultimate Tips for Choosing Stainless Steel Woven Wire Mesh

This bar chart provides a comparison of the corrosion resistance levels of various types of stainless steel used in woven wire mesh. Understanding these properties can help you make an informed choice for your specific application needs.

Types of Stainless Steel Woven Wire Mesh and Their Applications

Stainless steel woven wire mesh comes in various types, each serving unique purposes. The most common type is plain weave, which consists of horizontal and vertical wires tightly woven together. This type offers excellent strength and is often used in industrial settings. Another variant is the twill weave, known for its flexibility and durability. It provides a tighter mesh that is ideal for filtration applications.

Expanded metal mesh is another option that stands out. It is formed by cutting and stretching a flat sheet of stainless steel. The result is a lightweight mesh that provides excellent airflow. This is often used in architectural applications. On the other hand, decorative mesh panels can add an aesthetic touch to various designs. These panels are perfect for use in facades or screens.

It’s crucial to consider the application when choosing a mesh type. Each type has its strengths and limitations. For instance, not all meshes hold up well in extreme temperatures or corrosive environments. Testing different options may be necessary to find the right fit for your needs. Ensuring proper selection can prevent costly mistakes down the line. Reactive surfaces can be an issue if you overlook specific material interactions.

Ultimate Tips for Choosing Stainless Steel Woven Wire Mesh

| Type | Description | Common Applications | Wire Diameter (mm) | Mesh Opening Size (mm) |

|---|---|---|---|---|

| Plain Weave | The most common weave with equal spacing of warp and weft wires. | Filtration, screen dividers, and architectural applications. | 0.5 - 3.0 | 0.5 - 10.0 |

| Twilled Weave | Stronger weave where the wires cross over two weft wires alternatively. | Mining, petrochemical, and food processing. | 1.0 - 4.0 | 1.0 - 15.0 |

| Dutch Weave | Tight weave providing excellent filtration with a smaller opening on one side. | Liquid filtration, pharmaceutical, and chemical industries. | 0.3 - 2.0 | 0.1 - 5.0 |

| Reverse Dutch Weave | A variation of Dutch weave with thicker warp wires than weft wires. | Gas filtration, sugar and syrup filtration. | 0.4 - 2.5 | 0.2 - 4.0 |

Key Factors to Consider When Sizing Wire Mesh

When sizing stainless steel woven wire mesh, several factors play a crucial role. The mesh's aperture size is vital. Smaller apertures retain finer particles but may restrict fluid flow. A report by the International Wire Mesh Manufacturers Association indicates that optimizing aperture size can enhance filtration efficiency by up to 30%. Finding the right balance between filtration and flow is essential for many applications.

Wire diameter significantly influences mesh strength and durability. Thicker wires provide more mechanical strength, while thinner wires offer better flow characteristics. According to industry standards, a wire diameter of 0.2 mm can support lighter applications, whereas a diameter of 1.2 mm suits heavy-duty uses. Overlooking these specifications might result in structural failures or inefficiencies.

Consider the overall mesh dimensions too. The length and width should fit your project requirements without excess material. Excess mesh can waste resources and complicate installation. It's a common mistake to order standard sizes without evaluating specific needs. A tailored approach can often prevent costly adjustments later in the process. The failure to assess all these dimensions can lead to performance issues or increased operational costs.

Assessing Wire Diameter and Mesh Opening for Optimal Performance

When selecting stainless steel woven wire mesh, the wire diameter and mesh opening are crucial factors. A thicker wire often provides better strength and durability. However, it can also reduce flexibility. If you choose a wire that is too thick, it may not conform to your application’s needs. Finding a balance between strength and adaptability is key.

Mesh opening plays a significant role in filtration and strength. Larger openings allow more flow but may reduce structural integrity. Smaller openings provide better filtration but can restrict flow. This decision can greatly impact the performance of your project. A mesh with a too-small opening may clog quickly, requiring constant maintenance.

Always consider the specific application. Evaluate how the mesh will be used and what materials will pass through it. A common mistake is underestimating the impact of these choices. Take time to assess your needs and the environment. The right diameter and opening can dramatically affect your results, for better or worse.

Comparing Costs: Quality vs. Affordability in Wire Mesh Selection

When choosing stainless steel woven wire mesh, cost often plays a major role. A recent industry report indicates that high-quality wire mesh can range from $1.50 to $5.00 per square foot, depending on specifications. On the other hand, more affordable options can start as low as $0.50 per square foot. However, lower cost does not always equate to better value.

While it is tempting to prioritize affordability, consider the long-term implications. Lower-priced wire mesh products may have reduced strength or corrosion resistance. For example, mesh with lower-grade stainless steel may corrode faster, potentially leading to higher replacement costs. A study found that investing in quality mesh can ultimately save businesses up to 25% over five years in maintenance and replacements.

Choosing the right balance between cost and quality is crucial. It requires careful evaluation. Understand your specific needs before making a decision. This can prevent future regrets. Ultimately, the decision should reflect both immediate budgetary concerns and long-term performance expectations.