- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

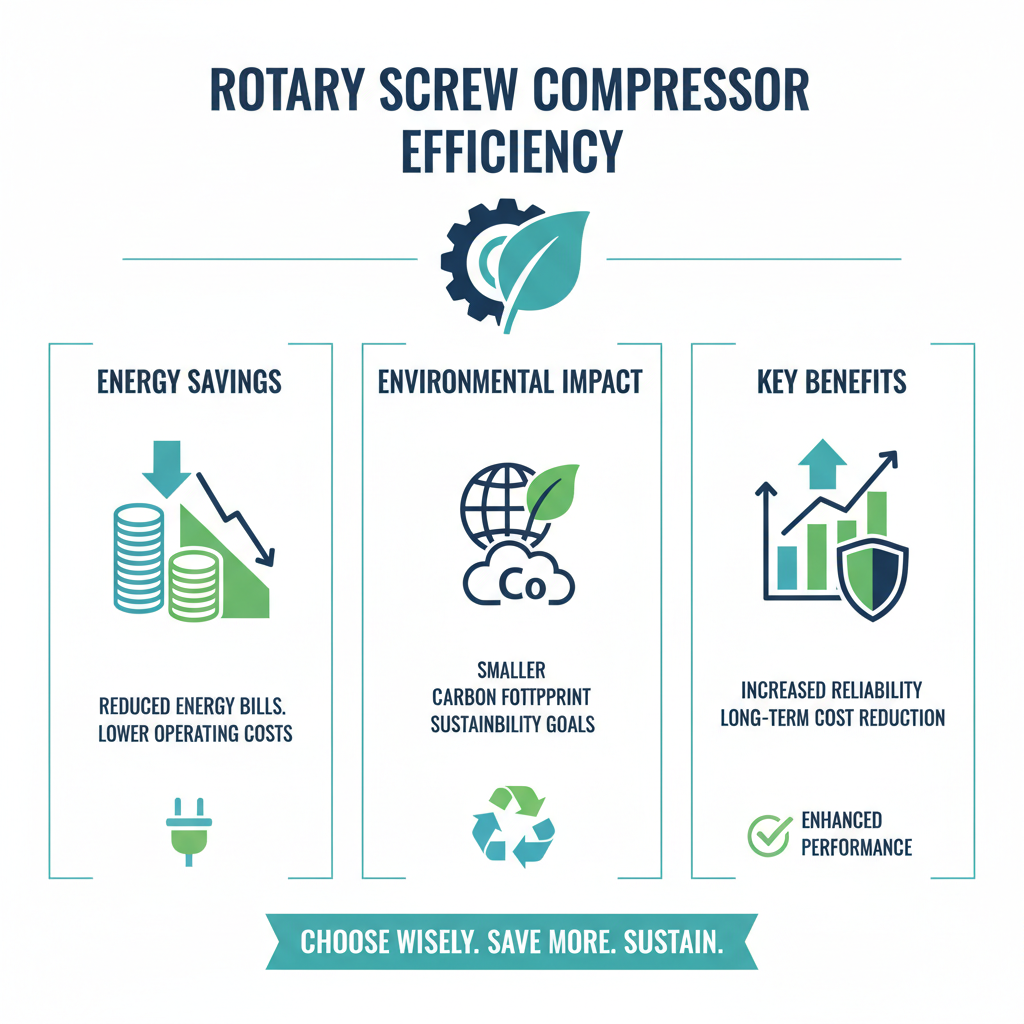

Essential Tips for Choosing the Right Rotary Screw Compressor for Your Needs

When it comes to industrial application, selecting the right rotary screw compressor is crucial for ensuring efficient and cost-effective operations. According to a report by MarketsandMarkets, the global market for rotary screw compressors is projected to reach $9.5 billion by 2025, driven by an increasing demand for energy-efficient solutions across various sectors, including manufacturing, construction, and automotive. The efficiency of these compressors not only influences operational costs but also plays a significant role in environmental sustainability, as industries strive to reduce their carbon footprint.

Moreover, a comprehensive study by Research and Markets highlights that rotary screw compressors offer distinct advantages over reciprocating compressors, such as lower noise levels, continuous airflow, and reduced maintenance requirements. With the right selection, businesses can enhance productivity and reliability while minimizing energy consumption.

Therefore, understanding the critical factors, from capacity and power requirements to technological features and maintenance needs, is vital for making an informed decision when investing in a rotary screw compressor. In this article, we will discuss essential tips that will guide you in choosing the right rotary screw compressor tailored to your specific needs.

Key Factors to Consider When Selecting a Rotary Screw Compressor

When selecting a rotary screw compressor, it is essential to evaluate several key factors to ensure optimal performance and efficiency. First and foremost, understanding the required air demand is crucial. According to a report from the CAGI, underestimating air requirements can lead to unnecessary operational costs, as compressors may run continuously or struggle to meet demands. It's advisable to calculate the peak and average consumption accurately to select a compressor with adequate capacity.

Another significant aspect is the energy efficiency of the compressor. Research indicates that energy costs can account for as much as 70% of the total lifecycle cost of a rotary screw compressor. Choosing a model with a high-efficiency rating can yield substantial savings over time. Users should look for units equipped with advanced control systems that can optimize power usage based on real-time air demand.

Tips: Always consider maintenance requirements and warranties offered by manufacturers. A unit that is easier to maintain will prevent downtime, while robust warranty support can protect your investment. Additionally, evaluate your installation space and the compressor's noise levels to ensure it meets your facility's operational environment without causing disruptions.

Understanding the Different Types of Rotary Screw Compressors Available

When selecting a rotary screw compressor, it is crucial to understand the different types available on the market to ensure you choose the right one for your specific needs. The two primary types are oil-injected and oil-free rotary screw compressors. Oil-injected compressors are more commonly used in industrial applications due to their efficiency and ability to handle high-duty cycles. They mix oil with compressed air, which helps in lubrication and cooling of the compressor, resulting in a longer lifespan and lower maintenance costs.

On the other hand, oil-free rotary screw compressors are ideal for applications where air purity is critical, such as in the food and pharmaceutical industries. These compressors use advanced technology to avoid oil contamination, providing clean air without compromising efficiency. Additionally, variations exist within each type, including variable-speed drive compressors that can adjust their speed based on demand, leading to energy savings and optimal performance. Understanding these differences will empower you to make an informed decision tailored to your operational requirements.

Essential Tips for Choosing the Right Rotary Screw Compressor for Your Needs

| Type | Description | Typical Applications | Horsepower Range | Efficiency |

|---|---|---|---|---|

| Oil-Flooded | Uses oil to enhance lubrication and cooling. | Manufacturing, pneumatic tools. | 5 - 500 HP | High Efficiency |

| Oil-Free | Provides clean air without oil contamination. | Food and beverage, pharmaceuticals. | 10 - 300 HP | Very High Efficiency |

| Stationary | Fixed installation; ideal for consistent demand. | Industrial settings. | 15 - 600 HP | High Efficiency |

| Portable | Mobile units suitable for various locations. | Construction, outdoor applications. | 3 - 25 HP | Moderate Efficiency |

Evaluating Compressor Size and Capacity for Your Application Needs

When selecting a rotary screw compressor, evaluating the size and capacity for your specific application is crucial. The compressor's capacity, measured in cubic feet per minute (CFM), determines the volume of air it can deliver. To ensure optimal performance, assess your peak air demand during operation. If your requirements fluctuate, choose a compressor that can handle the maximum demand while providing some headroom to avoid overloading.

When it comes to selecting the right size compressor, consider the following tips: first, calculate your average and peak CFM needs accurately. Use tools like flow meters to get precise measurements of your existing systems. Second, account for any future growth in your operations. Opting for a compressor with extra capacity can save you from potential costs of unnecessary replacements down the line. Lastly, always check the duty cycle of the compressor. For continuous operations, a model with a higher duty cycle rating will ensure reliability without overheating or excessive wear.

Each component of your system plays a role in efficiency, so don't underestimate the importance of compatibility between the compressor and your application. This ensures not just performance, but longevity of your equipment as well. By carefully evaluating these aspects, you’ll choose a rotary screw compressor that meets your current and future needs.

Importance of Efficiency Ratings: Energy Costs and Operational Impact

When selecting a rotary screw compressor, the efficiency ratings are paramount, particularly in the context of energy costs and operational impact. As organizations increasingly focus on sustainability and cost reduction, understanding the energy utilization of compressors becomes essential. Higher efficiency ratings not only reduce energy bills but also minimize the carbon footprint of the operations, aligning with global trends towards more environmentally responsible practices.

One effective tip is to assess the compressor's power consumption relative to its output. Look for models with variable speed drives, as these can adjust operations based on demand, ultimately leading to improved efficiency. Additionally, consider the Total Cost of Ownership (TCO), which includes initial purchasing costs, maintenance, and energy consumption over time. Selecting a compressor that strikes the right balance between performance and energy efficiency can lead to significant savings in the long run.

Furthermore, it is wise to evaluate the compressor’s operational parameters such as duty cycle and load management. Understanding these aspects helps in predicting energy consumption and optimizing the compressor's performance for specific applications. With the fast-evolving landscape of energy management, investing in a rotary screw compressor with strong efficiency ratings is more crucial than ever.

Maintenance Requirements and Longevity of Rotary Screw Compressors

When choosing a rotary screw compressor, understanding its maintenance requirements is crucial to ensure its longevity. Regular maintenance tasks such as changing the oil, cleaning or replacing air filters, and monitoring the system's performance can significantly extend the lifespan of the compressor. Routine checks help in identifying potential issues before they escalate, allowing for timely interventions that prevent costly breakdowns. Moreover, adhering to the manufacturer's guidelines for maintenance schedules is essential for optimal operation and longevity.

In addition to routine maintenance, the environment in which the compressor operates can affect its durability. Factors such as ambient temperature, humidity, and dust levels must be managed to create an ideal operating condition. Installing the compressor in a clean, well-ventilated area, away from extreme temperatures and excessive humidity, can further enhance its lifespan. Investing in high-quality parts and regular professional servicing not only keeps the compressor running smoothly but also ensures that it meets the operational demands efficiently over time.

Related Posts

-

Why Choose a Rotary Screw Air Compressor for Your Industrial Needs?

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping