- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

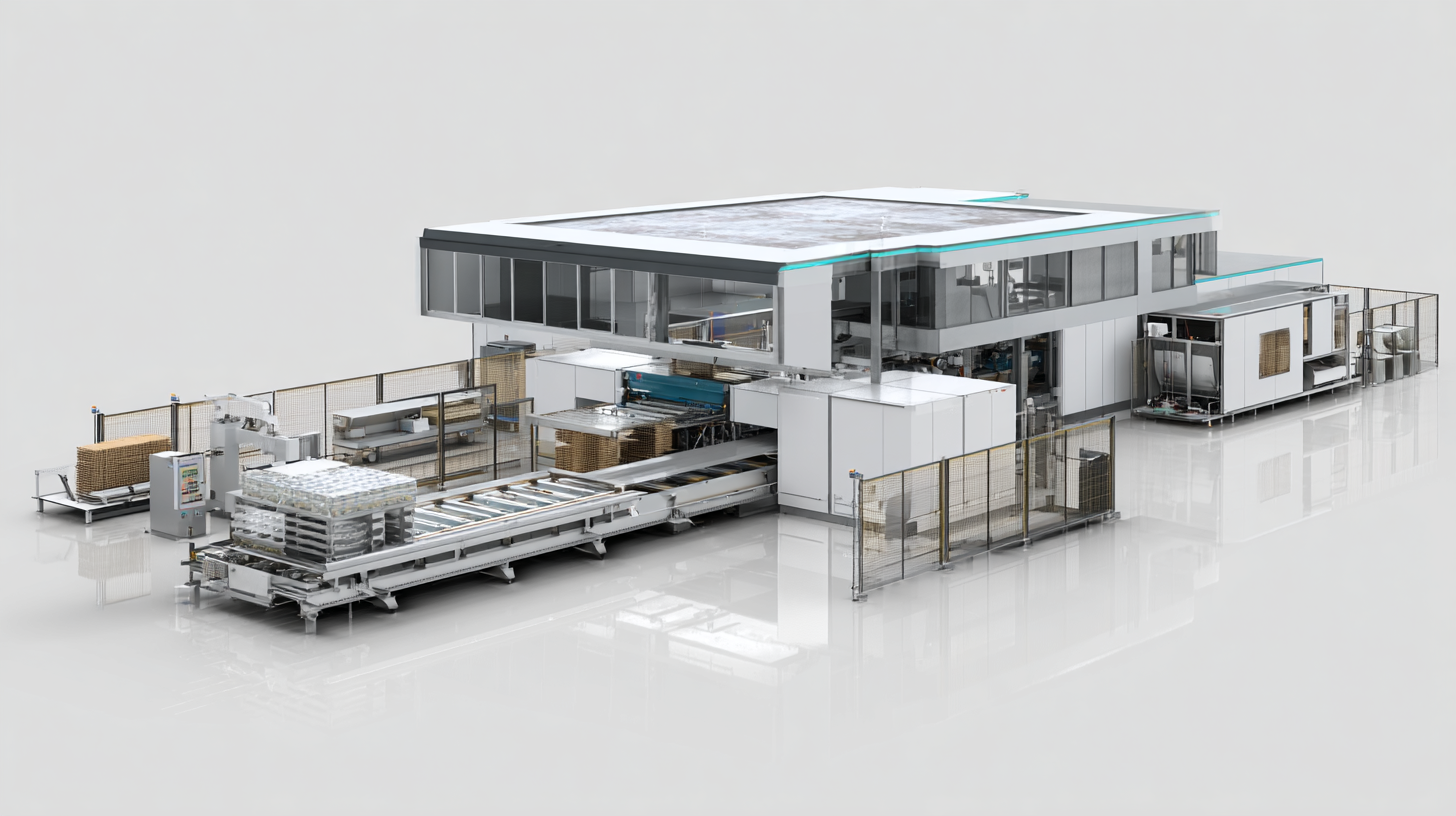

In the rapidly evolving landscape of furniture manufacturing, the incorporation of advanced technologies has become paramount to enhancing production efficiency and product quality. One standout innovation in this realm is the edge banding machine, which plays a crucial role in ensuring that furniture pieces not only look professional but also exhibit durability. As manufacturers face increasing pressure to meet consumer demands for high-quality, aesthetically pleasing furniture, edge banding machines have emerged as essential tools.

These machines streamline the process of applying edge banding material, significantly reducing labor time while increasing accuracy. In this article, we will explore the transformative impact of edge banding machines on the manufacturing process, providing valuable tips and insights for industry professionals looking to optimize their operations and stay competitive in a dynamic market.

The Evolution of Edge Banding Technology in Furniture Manufacturing

The evolution of edge banding technology in furniture manufacturing has been pivotal in enhancing production efficiency. As the furniture and woodworking industry in India sees remarkable growth, the introduction of advanced edge banding machines is transforming the way manufacturers approach production. With the thermoplastic edge band market poised to expand, driven by increasing construction and decorative needs, manufacturers are adopting innovative solutions to meet the rising demand. Reports suggest that the market for thermoplastic edges is expected to witness steady growth, reflecting broader trends in furniture production as companies pivot towards automation and efficiency.

Tips: When considering edge banding technology, manufacturers should focus on machine versatility and speed. Investing in machines that can handle various materials and thicknesses enables quicker adaptations to market demands. Another essential tip is to train staff adequately on the new machinery to maximize operational benefits.

As edge banding technology continues to evolve, its implementation facilitates not only higher quality finishes but also improves turnaround times. This aligns with market forecasts that predict significant growth in related sectors, with decor paper projected to increase from USD 5.39 billion in 2025 to USD 7.84 billion by 2035, showing the interconnectedness of trends in the furniture industry and the technological advancements applied therein.

Key Benefits of Automating Edge Banding Processes

Automating edge banding processes in furniture manufacturing offers significant benefits that enhance production efficiency and product quality. One of the primary advantages is the reduction of labor costs. By integrating edge banding machines, companies can minimize the time and manpower needed for manual edge finishing. This allows skilled workers to focus on more complex tasks, ultimately streamlining the overall manufacturing process.

Moreover, automated edge banding machines ensure consistent quality across all products. Unlike manual methods, which can vary in precision and speed depending on the worker, these machines maintain uniform application of the edge banding material. This leads to fewer defects and reduces waste, contributing to more sustainable production practices. Additionally, with faster processing times, manufacturers can increase their output, meet customer demands more efficiently, and gain a competitive edge in the market.

Industry Statistics: Impact of Edge Banding on Production Rates

In modern furniture manufacturing, edge banding machines play a crucial role in enhancing production efficiency. By employing advanced edge banding technologies, manufacturers can significantly reduce the time and labor required for finishing products. This efficiency is reflected in the rising adoption of automated edge banding solutions, which allow companies to meet high volume production demands while maintaining consistent quality. The precision of these machines minimizes material waste, ensuring that resources are optimized throughout the manufacturing process.

Industry statistics further emphasize the impact of edge banding on production rates. As manufacturers increasingly invest in these technologies, they are not only boosting output but also improving profit margins. Studies indicate that the integration of edge banding machines can lead to production rate increases of up to 30%, allowing companies to respond more effectively to market demands. As the furniture market continues to evolve, the strategic implementation of edge banding is set to become a key differentiator for manufacturers striving to enhance their operational efficiency and competitiveness.

Impact of Edge Banding Machines on Production Efficiency

Comparative Analysis of Traditional vs. Modern Edge Banding Machines

In the evolving landscape of furniture manufacturing, edge banding machines play a crucial role in streamlining production processes. Traditional edge banding methods, often labor-intensive and time-consuming, have been overshadowed by modern machines that leverage advanced technology. According to a recent report from the International Woodworking Machinery Association, businesses that integrated modern edge banding machines experienced a 30% increase in production efficiency and a significant reduction in labor costs.

Modern edge banding machines are equipped with automation features that minimize human error and optimize material usage. A study conducted by the Woodworking Industry Association indicated that manufacturers utilizing these upgraded machines reported a 50% decrease in edge banding defects. This not only enhances the aesthetic quality of the final product but also leads to substantial cost savings in rework and material waste.

Tips: When considering an upgrade to edge banding technology, evaluate the design complexity of your furniture pieces. Advanced machines often come with capabilities to handle intricate designs more efficiently. Additionally, partnering with reputable suppliers can ensure that you receive comprehensive training and support on the new systems, maximizing your return on investment.

Future Trends in Edge Banding Technology and their Implications for Furniture Production

The future of edge banding technology promises to significantly transform the landscape of furniture production. One important trend is the integration of automation and robotics. Advanced edge banding machines equipped with AI-driven systems can optimize the various stages of production, from material handling to machine calibration. This not only enhances precision but also reduces human error, leading to high-quality finishes and smoother workflows.

Another emerging trend is the adoption of sustainable materials and environmentally friendly practices within the edge banding process. As consumer demand for eco-friendly furniture increases, manufacturers are beginning to utilize bio-based adhesives and recycled materials. This shift not only aligns with global sustainability goals but also caters to an increasingly eco-conscious market, giving manufacturers a competitive edge. The combination of automation and sustainability in edge banding technology is set to redefine efficiency and creativity in furniture manufacturing.