- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

How to Optimize C and C Machine Operations for Maximum Efficiency?

The optimization of C and C machine operations is crucial in today's competitive landscape. Reports show that efficient machine operations can increase productivity by up to 30%. However, many facilities still experience downtime and inefficiencies. According to industry studies, 60% of C and C machine operators face challenges in achieving optimal performance.

To maximize efficiency, companies must focus on regular maintenance and employee training. For example, implementing a predictive maintenance strategy can reduce unexpected breakdowns. Employees trained in best practices can operate machines more effectively, which enhances output quality. Despite these advantages, many organizations overlook the importance of continuous improvement.

Addressing these inefficiencies is vital. Some companies struggle to integrate new technologies. Others may not fully utilize their C and C machines' capabilities. Each setback represents an opportunity for growth and reflection. By reevaluating their processes, businesses can unlock hidden potential and drive substantial gains in efficiency.

Understanding the Basics of C and C Machine Operations

C and C machines play a critical role in various industries, driving efficiency and productivity. Understanding their basic operations is essential for optimal results. C machines are designed for precise tasks, while C machines focus on versatility. Knowing how each machine operates helps users maximize their capabilities.

Basic operations begin with machine setup. Proper calibration can greatly influence performance. Misalignment can lead to inaccuracies, wasting time and materials. Operators need to routinely check settings to maintain consistency. It's easy to overlook these details, but they are vital for efficiency. Experimenting with different settings may also yield surprising results, though it takes patience.

Monitoring machine performance is just as crucial. Users often get caught up in speed, neglecting other important factors. Noise levels and vibration can indicate underlying issues. Addressing these concerns promptly can prevent costly downtimes. Additionally, ongoing training for operators can foster a deeper understanding of efficient practices. Errors will happen, but they provide valuable learning opportunities. Embracing this mindset can lead to continuous improvement in operations.

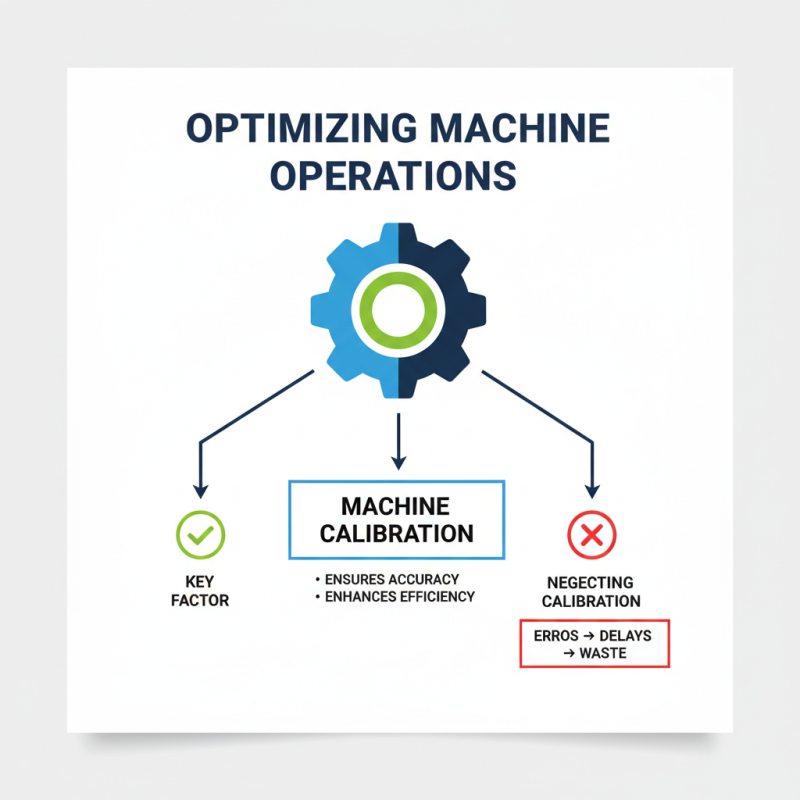

Identifying Key Factors Influencing Machine Efficiency

In optimizing machine operations, identifying key factors is essential. One of the most critical elements is machine calibration. Regular calibration ensures accuracy in operations, which can greatly enhance efficiency. Neglecting this can lead to errors, causing delays and waste.

Another significant factor is operator training. Well-trained operators can maximize machine capabilities. However, not all operators receive consistent training. This inconsistency often results in underutilized machines. It’s vital to invest time in upskilling the workforce. Mistakes made by untrained personnel can also lead to equipment damage, further hampering operations.

Maintenance practices play a crucial role in machine efficiency as well. Preventive maintenance can reduce unexpected breakdowns. Yet, many facilities ignore this until problems arise. This retroactive approach often leads to costly repairs and downtime. Regular inspections and timely repairs can help avoid these issues. Keeping track of maintenance schedules can be challenging but is necessary for smooth operations.

Implementing Best Practices for C and C Machine Maintenance

Maintaining C and C machine operations requires attention to detail. Regular inspections are essential. Operators should check for wear and tear. This includes belts, bearings, and lubricants. Neglecting these components can lead to breakdowns. A single oversight can disrupt the entire production line.

Implementing a daily checklist can promote consistency. This should include checking fluid levels and electrical connections. Operators should also log any unusual sounds or vibrations. These notes help in diagnosing problems early. Sometimes, machines can appear to run well but have underlying issues. Observations can reveal inefficiencies that need addressing.

Training staff on best practices is vital. Many operators may lack experience. Occasionally, they may overlook basic maintenance tasks. Encouraging a culture of responsibility can lead to improvements. Peer reviews can create an environment of shared learning. Machines are complex, and even minor mistakes can escalate into major problems. Fostering communication among teams can enhance machine care and operation.

Utilizing Technology for Enhanced Machine Performance

In today's fast-paced industrial world, optimizing C and C machine operations is crucial. Technology plays a vital role in enhancing machine performance. Many plants are adopting automation and smart machinery. This shift leads to increased productivity and reduced downtime.

Efficient data analysis is key. By monitoring machine performance in real-time, operators can identify issues quickly. Some machines are equipped with sensors that provide valuable feedback. This technology helps prevent unexpected failures, saving both time and money.

**Tips:** Regularly update software systems to ensure compatibility. Utilize predictive maintenance techniques to foresee potential issues. Engage in staff training to keep everyone informed about new technologies. Adopting these practices often reveals gaps in knowledge. Recognizing these can lead to better solutions. Sometimes, the technology can be overwhelming, and not all staff may adapt quickly. Embracing this challenge with a focus on continuous improvement will yield better results.

Measuring and Analyzing Performance Metrics for Optimization

Measuring and analyzing performance metrics is essential for optimizing C and C machine operations. It's crucial to understand how these metrics impact overall efficiency. Start by identifying key performance indicators (KPIs). Look at processing speed, memory usage, and system response times. These numbers reveal where improvements are needed.

Tips: Regularly benchmark your machines. Use tools that can quantify performance metrics. Check for unusual spikes in resource usage. This could indicate inefficiencies or potential issues. Consider tracking performance over time. This helps you see trends and make informed adjustments.

Remember, it’s easy to overlook minor issues. Small delays can accumulate and lead to larger problems. Analyzing these metrics provides insight but also calls for reflection. Are your current measures sufficient? Could the system be running more smoothly? Always question your benchmarks and look for continuous improvement.

Tips: Utilize visualization tools. Graphs and charts can make trends more apparent. They also help to pinpoint exact areas needing attention. Engaging your team in this process fosters collaboration. Sometimes, fresh perspectives can unveil solutions often missed by others. Stay proactive to ensure maximum efficiency in operations.

Performance Metrics for C and C++ Machine Operations

Related Posts

-

10 Essential Tips for Maximizing Efficiency with Your CNC Mill

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

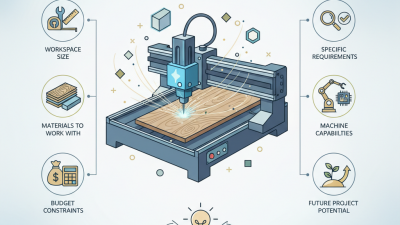

10 Essential Tips for Choosing the Right CNC Router for Your Projects

-

Best CNC Router Machine for Beginners and Professionals in 2023

-

Why You Should Consider a CNC Router for Your Next Project