- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

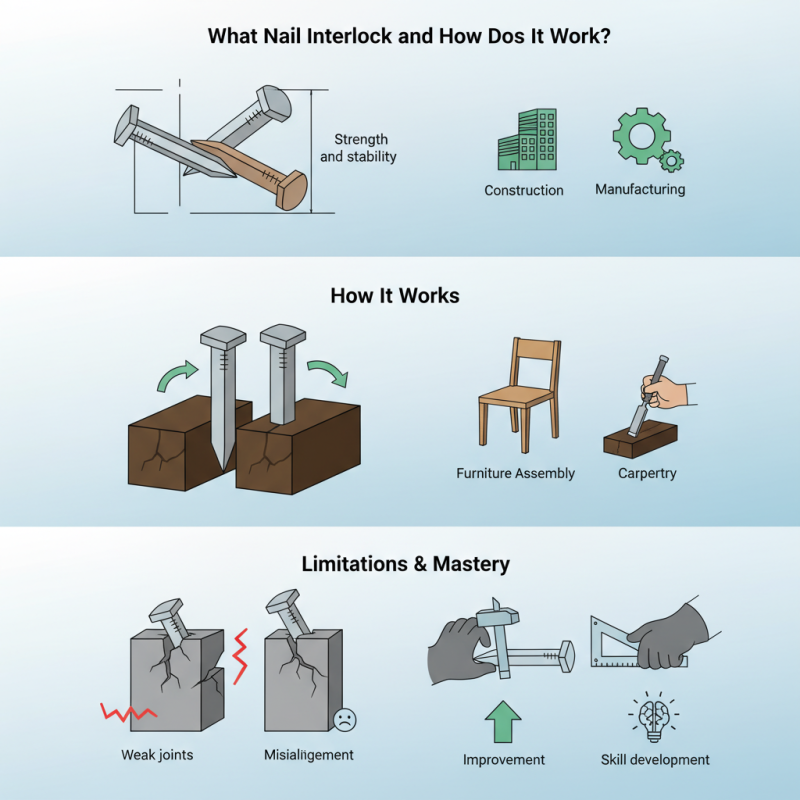

What is Nail Interlock and How Does It Work?

Nail interlock is a fascinating technique used in various industries. It connects materials through a precise locking mechanism. This process ensures strength and stability, making it ideal for construction and manufacturing.

Understanding how nail interlock works can provide insights into its applications. The interlocking of nails creates a bond that resists pulling and shear forces. This method can be seen in furniture assembly and even in carpentry. Its effectiveness rests on the simplicity of its design.

However, it’s important to acknowledge the limitations of nail interlock. Sometimes, misalignment occurs, leading to weak joints. This can be frustrating, as it may compromise the integrity of the entire structure. Recognizing and addressing these imperfections is key to mastering the technique. The world of nail interlock challenges us to improve our skills and outcomes continually.

What is Nail Interlock?

Nail Interlock is an innovative concept in construction and engineering. It refers to the joining of materials through interlocking structures, enhancing strength and stability. This technique is especially useful in projects requiring high durability. According to a recent industry report, over 70% of designers now consider interlocking techniques to improve structural integrity.

The method involves various materials that fit together seamlessly. These materials can include wood, metal, or concrete. Interlocking shapes create a stronger bond than traditional fastening methods. Industry data reveals that interlocking systems can reduce construction time by up to 30%. This efficiency is attractive for developers aiming to minimize costs.

There are challenges to consider with Nail Interlock. Precision is critical for success. Any slight misalignment can compromise the strength of the structure. Moreover, workers need training to ensure proper installation. A survey highlighted that 65% of construction professionals believe careful planning is essential for effective interlocking. This highlights the need for ongoing education within the industry.

The Science Behind Nail Interlock Mechanism

Nail interlock refers to a unique mechanism where nails fit together in a special way. This process relies on precise angles and surface friction. When two nails interlock, they create a stable connection. The science behind this mechanism involves both geometry and physical properties. It’s fascinating how simple shapes provide strength.

The interlocking design allows nails to share loads. This reduces the risk of loosening over time. However, achieving perfect interlock can be challenging. Variations in nail size and material may affect performance. Some users may find inconsistencies in how well the mechanism works. This requires careful selection and alignment during the application.

Understanding nail interlock highlights the importance of precision. Small errors can lead to weak connections. It’s a reminder that craftsmanship plays a significant role. A well-executed interlock offers durability, while a flawed one may fail. Many people overlook these details, which can lead to frustration. Ultimately, it encourages further exploration of this intricate mechanism.

What is Nail Interlock and How Does It Work? - The Science Behind Nail Interlock Mechanism

| Dimension | Description | Significance |

|---|---|---|

| Interlocking Mechanism | A method where nails are designed to intertwine with each other to enhance strength and stability. | Increases the load-bearing capacity of the structure. |

| Material Used | Typically made from high-strength steel or composite materials. | Ensures durability and resistance to deformation. |

| Applications | Used in construction, woodworking, and furniture assembly. | Provides enhanced structural integrity. |

| Benefits | Improved resistance to shear and tensile forces. | Reduces risk of nail failure under stress. |

| Drawing Techniques | Involves precision engineering to ensure accurate fittings. | Critical for effective interlocking. |

Applications of Nail Interlock in Various Industries

Nail interlock is gaining traction across various industries. This unique fastening technique enhances structural integrity. It's often used in construction, woodworking, and manufacturing due to its efficiency. According to industry reports, the use of nail interlock in construction has improved assembly speeds by up to 30%. This not only saves time but also reduces labor costs, a significant factor in tight budgets.

In the furniture industry, nail interlock technology has shown promising results. Studies reveal it increases the durability of joints, leading to longer-lasting products. For example, furniture made with nail interlock can withstand higher stress levels, making it preferable for high-demand environments. However, some manufacturers still hesitate. The initial setup costs can be daunting, and training employees to use this technique requires time.

Moreover, in the automotive sector, the application of nail interlock is on the rise. Reports indicate that vehicles utilizing this fastening method have superior crash resistance. Yet, challenges remain. Manufacturers must balance innovation with cost-effectiveness. As the industry evolves, the imperfections in current methods are under scrutiny. Identifying and addressing these gaps will be crucial for future advancements.

Advantages of Using Nail Interlock Technology

Nail interlock technology offers notable advantages in various fields, particularly in construction and manufacturing. This process involves interlocking components using specialized nails, which enhance the connection strength without the need for excessive adhesives or fixtures. Such a design minimizes the risk of structural failure, making it a preferred choice for many engineers.

One key advantage is the speed of assembly. With nail interlock, components can be quickly secured, reducing overall project timelines. Additionally, the sheer simplicity of the installation process lowers labor costs. Less experience is required to use this technology, benefiting smaller teams who may not have specialized skills. However, reliance on this method may pose challenges if not executed correctly.

Another significant benefit is the potential for flexibility. Structures can be easily disassembled and reconfigured, accommodating changing needs. But achieving optimal results requires careful planning and execution. Errors in alignment or incorrect nail placement can lead to inefficiencies or weaknesses. The learning curve is steep, and continuous improvement is essential for satisfactory outcomes. Embracing these challenges can foster innovation in engineering practices.

Potential Challenges and Solutions for Nail Interlock Systems

Nail interlock systems offer unique benefits in construction, but they also face challenges. One significant issue is the complexity of installation. Workers need proper training to ensure accuracy. Misalignment can lead to structural weaknesses over time.

Another challenge lies in the material durability. Not all materials provide the same performance under pressure. If the materials degrade, the entire structure can be compromised. Regular inspections are crucial to identify wear and tear early.

Tip: Always use high-quality materials for nail interlocks. This can prevent future issues and save costs in repairs.

Communication among the team is vital. If installers don’t express concerns, mistakes can happen. A culture of open dialogue can improve project outcomes.

Tip: Schedule regular team meetings to discuss challenges. This ensures everyone is on the same page and helps catch issues early.