- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

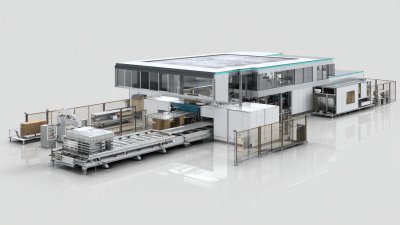

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

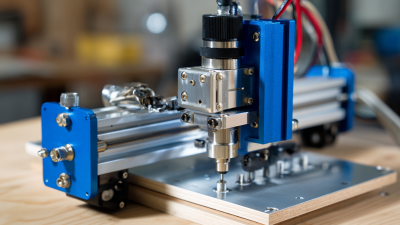

10 Essential Tips for Maximizing Efficiency with Your CNC Mill

In the ever-evolving landscape of manufacturing, maximizing efficiency with your CNC mill is more critical than ever. According to a recent report by Technavio, the global CNC machining market is projected to grow at a compound annual growth rate (CAGR) of over 7% from 2021 to 2025. This growth underscores the increasing reliance on advanced manufacturing techniques, particularly CNC milling, which allows for precision and repeatability that manual machining simply cannot match. As businesses strive to remain competitive, mastering optimization strategies related to CNC mills can significantly impact productivity and profitability.

Efficiency in CNC milling can lead to reduced lead times, lower operational costs, and improved product quality. A study by the National Institute of Standards and Technology (NIST) highlights that companies employing optimized machining processes can achieve productivity gains of up to 30%. This staggering statistic emphasizes the importance of adopting best practices in CNC milling. By focusing on techniques such as tool path optimization, appropriate feed rates, and regular maintenance, manufacturers can harness the full potential of their CNC mills, ensuring sustainable growth and improved outcomes in the fast-paced manufacturing sector.

Mastering Tool Selection for Optimal CNC Milling Performance

When it comes to optimizing CNC milling performance, mastering tool selection is crucial. The right tools not only improve the quality of the finished product but also enhance overall machining efficiency. One of the fundamental aspects of tool selection is understanding the importance of tool balancing. Properly balanced tools minimize vibrations during the machining process, which can lead to increased tool life and improved surface finish. This fundamental element ensures that the cutting edge remains stable, reducing wear and tear while delivering consistent results.

In addition to selecting the right tools, maintaining proper tool balancing directly affects the machining process. Unbalanced tools can cause excessive vibration, resulting in inaccurate cuts and even damage to the CNC mill. By focusing on precise tool balancing, machinists can significantly enhance the performance of their CNC mills, yielding better results, reducing downtime, and ultimately improving productivity. Investing time and resources in mastering tool selection and balancing will pay off in the long run, as it lays the foundation for a more efficient and effective machining operation.

Maximizing Efficiency with CNC Mills

Understanding CNC Programming Techniques to Boost Productivity

As industries embrace new digital manufacturing technologies, understanding CNC programming techniques is crucial for enhancing productivity. The CNC machining service market is witnessing significant growth, with a projected increase from $540.2 billion in 2025 to $1,083 billion by 2035, exhibiting an impressive compound annual growth rate (CAGR) of 8.04%. This growth highlights the demand for precision and efficiency in manufacturing processes, pushing companies to adopt advanced CNC solutions that optimize workflow and reduce manual errors.

Moreover, the CNC tube bending machine market is expected to reach a value of $558.65 million by 2024, growing to $852.88 million by 2032, with a CAGR of 5.43%. Such advancements in CNC technology are pivotal as they provide manufacturers with environmentally friendly operational solutions, transitioning from traditional practices to fully automated systems. The focus on adopting new technologies in CNC machining not only boosts productivity but also aligns with global trends emphasizing sustainable practices in manufacturing. Properly leveraging these techniques can lead to improved product quality, which is essential for maintaining competitiveness in today’s complex market landscape.

Implementing Effective Maintenance Practices for CNC Machinery

When it comes to maximizing efficiency with your CNC mill, implementing effective maintenance practices is crucial. Regular maintenance not only prolongs the life of the machine but also ensures optimal performance. One of the most important tips is to establish a routine inspection schedule. This includes checking coolant levels, inspecting belts and bearings for wear, and ensuring that electronic components are functioning properly. A well-maintained machine can operate at peak efficiency, reducing downtime and minimizing costly repairs.

Another essential tip is to clean your CNC mill regularly to prevent debris buildup, which can lead to inaccuracies and machine failure. Using the appropriate cleaning solutions and methods will help keep the machine free of contaminants that can affect precision. Additionally, consider lubricating moving parts often to reduce friction and wear, which is critical for maintaining smooth operation. Implementing these maintenance practices will significantly enhance your machine's productivity and reliability, leading to more efficient machining processes.

Utilizing Workflow Automation to Enhance CNC Mill Efficiency

In the rapidly evolving landscape of manufacturing, integrating workflow automation with CNC milling operations has proven to boost efficiency significantly. According to a report by the International Data Corporation, manufacturers adopting automation technologies have reported efficiency improvements of up to 30%, enabling them to streamline processes and reduce production downtime. By automating repetitive tasks such as tool changing and part setup, CNC mills can operate continuously, leading to faster turnaround times and increased output.

Moreover, workflow automation facilitates real-time monitoring and data analysis, allowing manufacturers to make informed decisions swiftly. A survey conducted by the Association for Manufacturing Technology (AMT) reveals that companies utilizing predictive analytics in their CNC mills have seen a reduction in unplanned downtime by as much as 20%. This proactive approach not only minimizes disruptions but also enhances the overall reliability of production schedules. As automation continues to advance, embracing these technologies will be crucial for manufacturers looking to stay competitive and maximize the potential of their CNC milling processes.

Analyzing Material Properties for Better Milling Outcomes

Understanding the properties of materials is crucial for achieving optimal results with your CNC mill. Different materials—such as aluminum, steel, and plastics—react uniquely under milling conditions, affecting everything from tool wear to cutting speed. According to a report by the Manufacturing Institute, over 30% of machining errors can be linked to improper material analysis. By conducting a thorough examination of material properties, including hardness, tensile strength, and thermal conductivity, machinists can tailor their milling processes to enhance productivity and precision.

To maximize efficiency, it is essential to select the right tools and parameters based on material characteristics. For example, when milling aluminum, a higher spindle speed and feed rate can be effective due to its softer nature. Conversely, harder materials like stainless steel require slower speeds and more robust tooling to prevent chipping and tool wear. Remember, using the appropriate cutting fluid can also improve outcomes by reducing thermal buildup and aiding chip removal.

Investing time in understanding material properties not only streamlines the milling process but also promotes better output quality. By aligning tool selection and milling strategies with material characteristics, users can decrease downtime and improve the longevity of their equipment. Analyzing these factors beforehand allows for a more calculated, efficient milling environment.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects