- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

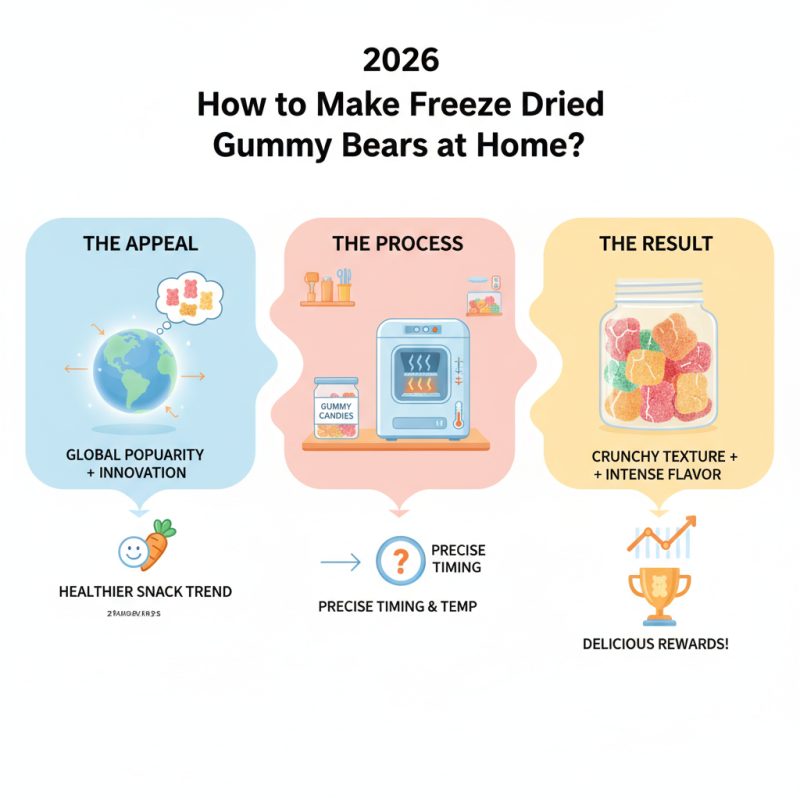

2026 How to Make Freeze Dried Gummy Bears at Home?

In recent years, the popularity of Freeze Dried Gummy Bears has surged. According to market research, the global gummy candy industry is expected to grow significantly, with trends highlighting innovative methods to enjoy these treats. Freeze drying offers a unique texture that retains the original flavor while making them light and crunchy.

Many home cooks are experimenting with freeze drying to create personalized snacks. A report from the National Confectioners Association revealed that over 60% of consumers seek healthier candy options. Freeze Dried Gummy Bears fit this trend perfectly. They provide a fun, nostalgic treat without the guilt of traditional gummy candies.

However, making these at home can be tricky. It's essential to monitor the process closely. Small variations in temperature or timing can affect the final outcome. The challenge lies in achieving that ideal crispy texture while preserving the flavor. For enthusiasts, the journey of making Freeze Dried Gummy Bears can lead to delicious rewards.

How Freeze Drying Works: The Science Behind the Process

Freeze drying, or lyophilization, is a fascinating process. It removes moisture from food while keeping its structure and nutrients intact. This method uses low temperatures and a vacuum to turn water into vapor. The absence of liquid water reduces spoilage and extends shelf life. The science behind freeze drying is both simple and complex. It’s about altering the state of water without going through a liquid phase.

To freeze dry gummy bears, you first freeze them at very low temperatures. This solidifies the sugar and gelatin structure of the gummies. Next, a vacuum is applied, allowing frozen water to sublime. While this sounds simple, achieving the right vacuum pressure can be tricky. If it's too high, gummies can collapse. If it’s too low, they’ll remain soggy. Achieving the perfect balance takes practice and careful monitoring.

After freeze drying, the gummy bears turn airy and crunchy. They maintain their shape but lose their chewy texture. Taste changes too; it's more concentrated. Some may prefer the classic chewy gummy version. Reflecting on this, it’s clear that experimenting is vital. Each batch can teach you something new. Adapt your methods and don't shy away from mistakes. Embrace the learning journey of making these unique treats.

Essential Ingredients for Making Gummy Bears at Home

Making freeze-dried gummy bears at home is a fun project. To start, you will need a few essential ingredients. Gelatin is the main component for the gummy texture. Make sure to choose high-quality gelatin for the best results.

Next, you’ll need flavored liquids. This could be fruit juice, soda, or flavored extracts. Natural colors usually enhance the appearance of your gummy bears. Don’t forget sugar, as it adds sweetness and helps with the consistency.

Tips: If you're experimenting with flavors, start with small amounts. Test different combinations. A common mistake is using too much liquid, which affects the texture. Freeze dryers can be expensive. If you don’t have one, consider air-drying or using an oven on low heat.

While making gummy bears, precision is key. Measure your ingredients carefully. Too much gelatin can make them rubbery. Too little may result in a mushy texture. It's all about finding the right balance. Creating the perfect gummy bear takes patience and practice. Don’t hesitate to tweak your recipe as you go!

Step-by-Step Guide to Freeze Drying Gummy Bears

Freeze drying gummy bears at home can be a fun and delicious project. Start by gathering your ingredients: gummy bears and a freeze dryer. If you don’t have a freeze dryer, consider other methods, but they may not yield the same results. Choose vibrant, colorful gummy bears for a visually appealing outcome.

Place the gummy bears on the freeze dryer trays, ensuring they are spaced apart. Avoid overcrowding to allow proper air circulation. Set the machine according to the manufacturer’s instructions, but it typically takes several hours. Keep an eye on the process; not all gummy bears will dry evenly. Some may require more time while others might become overly crunchy.

After the drying cycle completes, check the consistency. They should be lightweight and have a brittle texture. If they seem chewy, they may need more time. It's a learning experience—you might not get perfect results every time. Experimenting with different flavors and brands can give varying outcomes. Take notes on what works and what doesn't to improve future batches.

Ideal Temperature and Time Settings for Freeze Drying Snacks

When making freeze-dried gummy bears at home, temperature and time settings play a crucial role. Aim for a low temperature, ideally around 110°F. This helps preserve the flavors and textures of the gummy bears. A higher temperature may lead to uneven drying and a loss of taste. Patience is key here; you don't want to rush the process.

The drying time can vary considerably. Typically, it may take anywhere from 6 to 12 hours. It's wise to check them every few hours. If they feel sticky or moist, they need more time. A good batch should be completely dry and crunchy. Don’t be discouraged if your first attempt isn’t perfect; learning comes from doing.

Monitor the humidity levels during the drying process. Too much moisture can ruin your gummy bears. Keep your workspace clean and organized. This will help prevent cross-contamination. Remember, practice makes perfect. Enjoy the journey of creating the perfect freeze-dried snacks!

Freeze Dried Gummy Bears Preparation Time and Temperature

Nutritional Impact of Freeze Dried Gummy Bears vs Fresh Ones

Freeze-dried gummy bears have become popular for their unique texture and convenience. However, their nutritional profile differs significantly from fresh gummy bears. Fresh gummy bears are often high in sugars and contain minimal nutrients. In contrast, freeze-drying retains some of the fruit's vitamins while reducing volume and weight. According to the USDA, fresh fruit retains most vitamins, while freeze-dried variants maintain about 90% of vitamin C.

Yet, freeze-dried gummy bears still may lack fiber content when compared to whole fruit. Fiber is crucial for digestive health. Many make the mistake of thinking freeze-dried means completely healthy. While they have fewer calories per serving, they may still harbor added sugars and preservatives. A study by the Journal of Food Science suggests that some freeze-dried products can contain more concentrated sugars due to the removal of water. This can lead to unexpected calorie counts.

In terms of hydration, fresh gummy bears are higher in moisture content, equating to higher water intake when consumed. Those seeking a balanced diet should consider this aspect. Freeze-dried gummy bears may score high on fun and snackability, but they fall short in many essential nutrients. This highlights the importance of evaluating snack choices, rather than solely focusing on novelty or convenience.

2026 How to Make Freeze Dried Gummy Bears at Home? - Nutritional Impact of Freeze Dried Gummy Bears vs Fresh Ones

| Nutritional Component | Fresh Gummy Bears (per 100g) | Freeze Dried Gummy Bears (per 100g) |

|---|---|---|

| Calories | 320 kcal | 350 kcal |

| Total Carbohydrates | 78 g | 85 g |

| Sugars | 65 g | 75 g |

| Protein | 2 g | 1 g |

| Fat | 0 g | 0 g |

| Fiber | 0 g | 0 g |

| Vitamin C | 0 mg | 1 mg |

| Shelf Life | 1 year | 2+ years |