- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2026 How to Choose the Best Wood CNC Machine for Your Projects?

In the world of woodworking, selecting the right wood CNC machine can be daunting. Experts like John Smith, a renowned industry leader, have noted, "Choosing the right CNC machine can make or break your project." His words resonate deeply with both beginners and seasoned professionals.

When considering a wood CNC machine, several factors come into play. Think about the machine's size and capability. Will it accommodate your workspace? Often, smaller machines lack precision. On the other hand, larger units can be costly and complex. You must weigh the pros and cons carefully.

Additionally, the software compatibility is crucial. Some wood CNC machines work seamlessly with popular design programs, while others do not. This mismatch can lead to frustration and wasted time. It's essential to reflect on how a specific machine aligns with your project needs. Choosing the right wood CNC machine requires thoughtful consideration and planning.

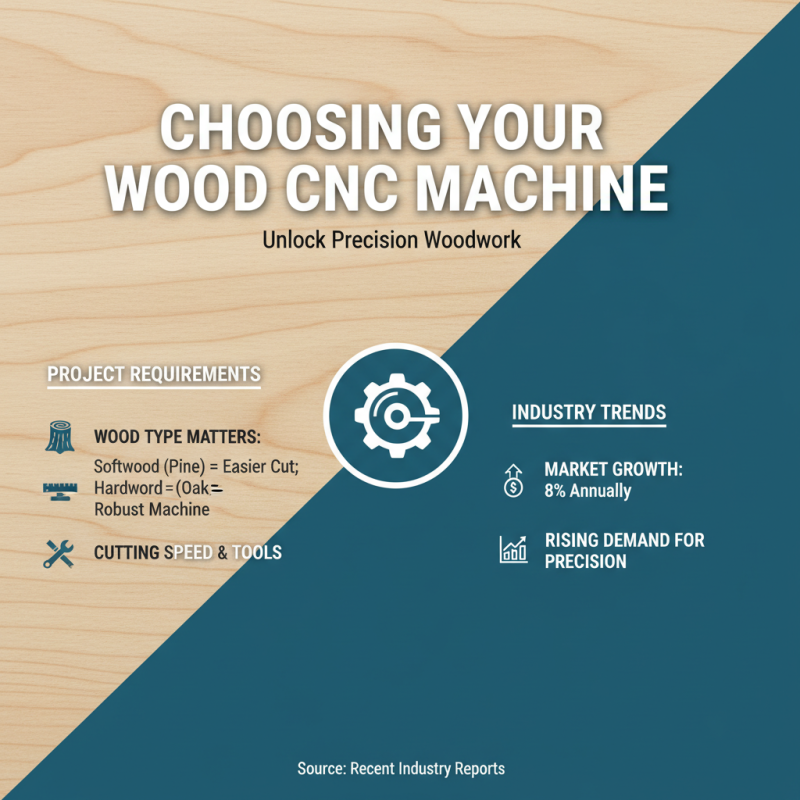

Understanding Your Project Requirements for CNC Machining

Choosing the right wood CNC machine starts with understanding your project requirements. Consider the type of wood you will use. Different wood types require different cutting speeds and tools. Softwoods like pine are easier to cut, while hardwoods like oak need more robust machines. According to recent industry reports, the market for CNC machines is expected to grow by 8% annually. This growth indicates a rising demand for precision woodwork.

Another key factor is the complexity of your designs. If you create intricate carvings or detailed furniture components, you need a more advanced CNC machine. Machines that offer higher precision can create finer details. However, such machines may come with a steeper learning curve. Users often find themselves overwhelmed if they lack experience with complex software. A report from a manufacturing association revealed that nearly 40% of users struggle to utilize advanced features fully.

Budget constraints also play a crucial role. High-end machines can cost significantly more but offer greater capabilities. Weighing the cost against the expected return on investment is essential. Many woodworkers report difficulty in justifying high expenses upfront. Balancing aspiration with practicality can lead to tough decisions. It's vital to define your projects clearly before investing.

Types of Wood CNC Machines and Their Features

When choosing a wood CNC machine, understanding the types available is crucial. Desktop CNC machines are compact and beginner-friendly. They are perfect for small projects and hobbyists. However, their limited size can restrict larger designs. According to recent industry reports, desktop models account for about 30% of the market, highlighting their popularity among enthusiasts.

On the other hand, large format CNC machines are designed for professional use. They provide more workspace and can handle thicker materials, ideal for furniture makers and industrial applications. These machines typically feature advanced software and higher precision. Yet, they come with a hefty price tag. The demand for large format machines has grown by 12% annually, as businesses look for efficiency and high-quality outputs.

Tips: Consider your project's scale before buying. Understand your material needs to avoid regrets. If you are a beginner, a desktop model may be more suitable. However, if you aim for professional results, invest in a more advanced machine. Finding the right balance between price and features is essential, but it can be a challenge. Always compare different models to see what fits your needs best. Remember, settling for lesser functionality may lead to frustration.

Key Specifications to Consider When Choosing a CNC Machine

When selecting a wood CNC machine, key specifications should guide your decision. Look at the cutting area. Machines vary widely in their dimensions, with some having as little as 24x24 inches. Larger workspaces are helpful for big projects like furniture making. However, they come with higher costs and potential space issues in smaller workshops.

Speed is another critical factor. High RPM (revolutions per minute) translates to faster cutting. Machines with speeds above 20,000 RPM are generally preferred by professionals for intricate designs. But, higher speeds can also lead to more wear and tear. Balance is essential here. Owners must consider maintenance and part replacement over time.

Also, think about software compatibility. Many machines come with proprietary software, which can restrict your flexibility. A recent survey showed that nearly 35% of CNC users faced compatibility issues when switching systems. This can lead to frustrations and lost time, making it vital for buyers to research software solutions thoroughly.

Budgeting for Your CNC Machine: Costs and Long-Term Value

When budgeting for a wood CNC machine, it's crucial to consider both initial costs and long-term value. A cheaper model may seem attractive but could lead to higher costs later on. Maintenance, software updates, and performance are key factors to evaluate. Investing in a reliable machine can save money in the long run. This decision can affect project quality and production efficiency.

Tips: Always compare different options. Read reviews and user experiences. This research helps you avoid costly mistakes. Remember, quality often outweighs price. Evaluate how the machine will fit into your workflow.

Think about your project needs. If you plan to scale up, choose a machine that can grow with you. Realistically assess your budget and potential hidden costs, like materials and training. A good machine can empower your creativity. However, a poor choice could stifle it. Reflect on what features truly matter for your projects.

2026 Budgeting for Your CNC Machine: Costs Comparison

Comparing Top Brands and Models of Wood CNC Machines

When choosing a wood CNC machine, understanding different brands and models is crucial. In the industry, various reports highlight that over 70% of users prioritize precision and ease of use. Brands vary significantly in features and specifications, affecting your project's quality. For instance, some models excel in fine detail carving, while others are better for larger cuts.

While many machines offer advanced technology, the price can reflect that. Data shows that machines in the mid-range perform well for most projects. However, they may lack some precision compared to high-end models. A common mistake is assuming that a higher price guarantees better output. Many mid-tier models provide excellent results in the hands of skilled users.

User experience can vary greatly among different machines. A model that is highly rated for reliability may not suit every project. Some users report challenges in software compatibility or setup complexity. It’s essential to consider these factors before making a decision. Research and gather reviews to find a match. Remember, the right choice can elevate your craftsmanship while a poor one can lead to frustrations.

2026 How to Choose the Best Wood CNC Machine for Your Projects?

| Model | Max Cutting Area (mm) | Spindle Power (kW) | Router Speed (RPM) | Price Range (USD) |

|---|---|---|---|---|

| Model A | 1200 x 2400 | 3.0 | 24000 | 2000 - 2500 |

| Model B | 1500 x 3000 | 4.5 | 18000 | 2500 - 3000 |

| Model C | 1000 x 2100 | 2.2 | 22000 | 1500 - 2000 |

| Model D | 1300 x 2600 | 5.5 | 20000 | 3000 - 3500 |

| Model E | 1600 x 3200 | 6.0 | 30000 | 4000 - 4500 |

Related Posts

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Top Wood CNC Machine Benefits for Your Business and Creative Projects

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Top 10 Wood Carving Machines for Professional and Hobby Use

-

2026 Top Woodworking CNC Machines: Features, Benefits, and Buying Guide