- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects

In the rapidly evolving landscape of manufacturing, the significance of precision and quality in production cannot be overstated. According to a report by MarketsandMarkets, the global CNC machining market is projected to grow from $63.8 billion in 2020 to $100.1 billion by 2025, underscoring the rising adoption of CNC machining parts across various industries, including automotive, aerospace, and medical devices. This growth highlights a fundamental shift towards automation and efficiency, where the choice of CNC machining parts plays a critical role in ensuring the success of projects.

Selecting the right CNC machining parts is essential for achieving the desired functional performance and longevity of products. Factors such as material selection, dimensional accuracy, and surface finish become paramount when choosing components for precision engineering applications. An insightful analysis from Deloitte indicates that 70% of manufacturers report an increased focus on supply chain resilience, which is directly linked to their choices of CNC machining parts. As such, understanding the intricacies of the CNC machining process and the various options available will empower engineers and project managers to make informed decisions that enhance productivity and innovation in their projects.

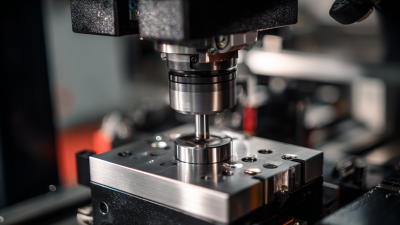

Understanding CNC Machining: Types and Applications of Numerical Control

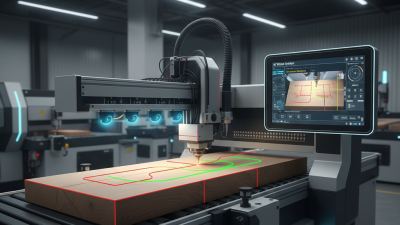

CNC (computer numerical control) machining is a pivotal technology in modern manufacturing, enabling precision and efficiency across various industries. Understanding the types and applications of CNC machining is essential for selecting the best parts for your projects. CNC machines are classified into several types, including milling machines, lathes, and plasma cutters, each suited for different manufacturing needs. For instance, milling machines are ideal for creating complex geometries, while lathes excel in producing cylindrical parts with high accuracy.

CNC (computer numerical control) machining is a pivotal technology in modern manufacturing, enabling precision and efficiency across various industries. Understanding the types and applications of CNC machining is essential for selecting the best parts for your projects. CNC machines are classified into several types, including milling machines, lathes, and plasma cutters, each suited for different manufacturing needs. For instance, milling machines are ideal for creating complex geometries, while lathes excel in producing cylindrical parts with high accuracy.

The applications of CNC machining span numerous sectors, including aerospace, automotive, and healthcare. In aerospace, CNC is used to manufacture intricate parts that meet stringent safety and performance standards. Similarly, the automotive industry relies on CNC machining for efficient production of components like precision shafts and threaded parts. As the market for CNC machines grows, projected to reach USD 170.4 billion by 2033, the technology is becoming increasingly vital in adapting to the demands of digital manufacturing and enhancing production processes across the globe.

Key Factors to Consider When Selecting CNC Machining Parts

When selecting CNC machining parts for your projects, it's essential to consider several key factors to ensure optimal performance and quality. First and foremost, the material used in the CNC parts plays a crucial role. Different materials exhibit varying properties like strength, durability, and machinability, which influence the final product's performance. Reports indicate that the global CNC machine market is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, achieving a compound annual growth rate of 9.9%. This rapid growth highlights the importance of making informed decisions about the components you choose for your machining needs.

When selecting CNC machining parts for your projects, it's essential to consider several key factors to ensure optimal performance and quality. First and foremost, the material used in the CNC parts plays a crucial role. Different materials exhibit varying properties like strength, durability, and machinability, which influence the final product's performance. Reports indicate that the global CNC machine market is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, achieving a compound annual growth rate of 9.9%. This rapid growth highlights the importance of making informed decisions about the components you choose for your machining needs.

Tips: Always analyze the specifications and tolerances required for your project and match them with the capabilities of the CNC machining parts. Investing in high-quality materials may result in higher upfront costs, but it often pays off through enhanced durability and reduced maintenance needs.

Another vital consideration is the reputation and reliability of the supplier. Collaborating with a trusted supplier can provide assurance of quality and consistency, which is crucial in industries where precision is non-negotiable. As the global CNC milling market is projected to grow significantly—from $16.63 billion in 2025 to $26.69 billion by 2033 at a CAGR of 6.1%—selecting the right partners can play a vital role in your project’s success.

Tips: Research potential suppliers thoroughly and look for reviews or case studies that demonstrate their reliability. Establishing long-term relationships with capable suppliers can streamline your production processes and enhance overall project outcomes.

Material Choices: Finding the Right Substance for Your CNC Projects

When embarking on CNC machining projects, selecting the right material is paramount to achieving desired results. According to a report by the CNC Manufacturers Association, over 70% of machining defects can be traced back to inappropriate material selection. Therefore, understanding the properties of various materials, such as aluminum, steel, and plastics, is essential. For instance, while aluminum offers excellent machinability and weight advantages, certain projects may demand the strength and durability of steel, particularly for parts subjected to high stress.

Tip: Always consider the environment the part will operate in. For applications exposed to chemicals, high temperatures, or extreme wear, materials like stainless steel or specialized polymers might be necessary.

Furthermore, advanced materials like carbon fiber composites are becoming increasingly popular due to their lightweight and high-strength characteristics, making them ideal for aerospace and automotive applications. A recent industry report suggests that the market for composite materials in CNC machining is expected to grow by 15% annually, indicating a shift towards more innovative solutions in material choices.

Tip: Consult with your CNC machining service provider to understand recent trends and technological advancements in material options, ensuring your project is both cost-effective and high quality.

Precision and Tolerances: Ensuring Quality in Machined Parts

When selecting CNC machining parts for your projects, precision and tolerances play a pivotal role in ensuring the quality of the final product. According to a recent report by Grand View Research, the global CNC machining market is projected to reach USD 100 billion by 2025, underscoring the growing importance of precision in manufacturing. Components machined to tight tolerances can drastically reduce the likelihood of defects, which are reported to increase manufacturing costs by up to 30%. This highlights the necessity of investing in parts that meet stringent precision standards to enhance both performance and reliability.

Machined parts with tolerances as tight as +/- 0.001 inches are often required in industries such as aerospace and medical device manufacturing, where even minor discrepancies can lead to significant safety issues or equipment failures. A study by Deloitte found that companies that prioritize precision engineering experience a 25% increase in operational efficiency. By carefully evaluating your project requirements and selecting CNC machining partners who leverage advanced technologies, such as multi-axis machining and real-time quality inspections, you can ensure that your parts meet the precise specifications necessary for success in today's competitive landscape.

2025 Guide: CNC Machining Parts Quality Analysis

Cost Analysis: Budgeting for CNC Machining Components

When budgeting for CNC machining components in 2025, understanding the true costs associated with each phase of the production process is crucial. The costs can vary significantly based on project requirements, including the complexity of designs, types of materials used, and the scale of production. From the design phase to the final application, cost control must be prioritized to avoid overruns that can derail project timelines and impact overall profitability.

**Tip:** Conduct a thorough cost analysis early in your project to identify potential financial challenges. Itemize all expenses, including design, tooling, and transportation to get a clear picture of your financial commitments.

Additionally, the precision tooling market is on a growth trajectory, suggesting that investing in high-quality components could lead to more efficient production and long-term savings. With expectations for increased market size and demand for CNC machining, budgeting appropriately for these high-precision components is vital.

**Tip:** Look for opportunities to streamline your processes. By investing in automation and advanced manufacturing techniques, you can reduce labor costs and improve overall efficiency, leading to lower long-term expenditures.

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects - Cost Analysis: Budgeting for CNC Machining Components

| Part Type | Material | Estimated Cost ($) | Lead Time (Days) | Tolerances (mm) |

|---|---|---|---|---|

| CNC Milling Part | Aluminum 6061 | 150 | 7 | ±0.05 |

| CNC Turning Part | Stainless Steel 316 | 200 | 10 | ±0.02 |

| CNC Router Part | Acrylic | 80 | 5 | ±0.1 |

| Laser Cut Part | Mild Steel | 120 | 4 | ±0.3 |

| 3D Printed Part | PLA | 70 | 3 | ±0.5 |

Related Posts

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss