- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

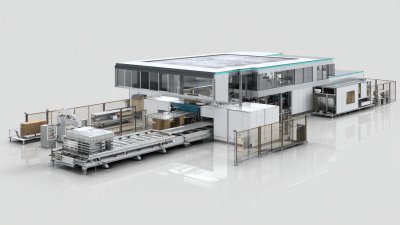

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

The evolution of manufacturing in the 21st century has been significantly influenced by advancements in technology, particularly the rise of CNC machining parts. These precision-engineered components have not only enhanced the efficiency of production processes but have also transformed the way industries approach design and fabrication.

The evolution of manufacturing in the 21st century has been significantly influenced by advancements in technology, particularly the rise of CNC machining parts. These precision-engineered components have not only enhanced the efficiency of production processes but have also transformed the way industries approach design and fabrication.

With the ability to create intricate shapes and details with remarkable accuracy, CNC machining parts streamline workflows and reduce lead times, allowing manufacturers to meet increasing demands for customization and rapid delivery.

This "how-to" guide will explore the pivotal role of CNC machining in revolutionizing production, offering insights into the processes, tools, and techniques that help businesses optimize their manufacturing capabilities and stay competitive in an ever-evolving market.

As we delve deeper, we will uncover the myriad benefits and applications of CNC machining parts, illuminating the path toward a more efficient and innovative future in manufacturing.

The Evolution of Manufacturing Technology in the 21st Century

The 21st century has witnessed a remarkable evolution in manufacturing technology, with CNC machining leading the charge in revolutionizing production processes. This evolution is characterized by enhanced precision, efficiency, and flexibility in manufacturing. As automated systems become integral to operations, the ability to produce complex designs with minimal human intervention allows industries to meet demand with unprecedented speed. CNC machines have transformed traditional production lines into sophisticated setups that can adapt quickly to market needs, fostering innovation in product design and overall manufacturing capabilities.

Tips: When considering CNC machining for your production processes, it is crucial to prioritize software capabilities. Invest in advanced CAD/CAM systems that enhance design accuracy and streamline the workflow from concept to final product. Furthermore, ensure you have a skilled workforce capable of operating these machines effectively, as their expertise can significantly impact the quality of the output.

As manufacturing technology continues to advance, the integration of CNC machining with emerging technologies such as IoT and AI is opening new horizons for efficiency and customization. This synergy is not only optimizing operational processes but also enabling manufacturers to implement smart factories that maximize resource utilization and minimize waste. Embracing these advancements can lead to significant competitive advantages in an increasingly dynamic marketplace.

Tips: Stay updated with industry trends by attending workshops or online courses on CNC technology. Regular training for your team can foster a culture of continuous improvement and innovation within your organization.

Understanding CNC Machining: Principles and Techniques

CNC machining, or Computer Numerical Control machining, has transformed traditional manufacturing processes by enabling precise and automated production of parts. At its core, CNC machining utilizes computer software to control machine tools, ensuring accuracy that is unattainable with manual methods. By inputting design specifications into a computer, manufacturers can create complex geometries and intricate designs, turning raw materials into finished components with minimal human intervention. This shift not only enhances precision but also significantly reduces the time needed for product development.

The principles of CNC machining involve a variety of techniques, including milling, turning, and grinding. Each method uses a specific type of machine tool controlled by a computer program, allowing for various shapes and sizes of parts to be manufactured efficiently. For example, milling involves the use of rotating tools to remove material from a workpiece, while turning involves rotating the workpiece itself against a stationary cutting tool. As industries continue to seek greater efficiency and quality in production, understanding these fundamental techniques of CNC machining becomes essential for harnessing their full potential in revolutionizing the manufacturing landscape.

Advantages of CNC Machining in Modern Production Lines

CNC machining has emerged as a cornerstone of modern manufacturing, offering numerous advantages that enhance production efficiency and precision. One of the key benefits is the ability to produce highly complex parts with minimal human intervention. Automated CNC machines operate based on precise digital inputs, ensuring that every component is crafted to exact specifications. This automation significantly reduces the risk of human error, leading to improved quality control and consistent output.

Another noteworthy advantage of CNC machining is its flexibility in production runs. Whether manufacturing a single prototype or large volumes of parts, CNC machines can be quickly reprogrammed to accommodate different designs. This adaptability allows manufacturers to respond swiftly to market demands, enabling them to introduce new products without the need for extensive downtime or costly retooling.

Furthermore, the capability to use a wide variety of materials—from metals to plastics—strengthens its position as a versatile solution in diverse industries. Overall, the implementation of CNC machining in production lines signifies a transformative shift that optimizes efficiency and drives innovation in manufacturing processes.

Applications of CNC Machining Across Various Industries

The adoption of CNC machining technology has brought transformative impacts across various industries, enhancing efficiency and precision in production processes. With the precision turned product manufacturing market projected to reach USD 196.11 billion by 2034, CNC machining is becoming increasingly vital for producing components such as precision shafts, pins, and threaded elements. These components are essential in automotive, aerospace, and consumer electronics sectors, where accuracy and reliability are paramount.

Furthermore, the global plate rolling machine market is anticipated to grow to USD 638.37 million by 2034, reflecting a 5.1% CAGR. This increase signals the growing demand for custom and advanced manufacturing solutions, where CNC machining plays a crucial role by allowing for the seamless production of complex shapes and sizes. Additionally, the end milling machine market is set to expand significantly from 2025 to 2035, highlighting the continuous innovations in automated machining processes that enhance productivity and adaptability in manufacturing operations across various applications.

The Future of Manufacturing: How CNC Machining Parts Revolutionize Production Processes

| Industry | CNC Machining Applications | Benefits | Trends |

|---|---|---|---|

| Aerospace | Precision components, prototypes | High accuracy, lightweight parts | Increased use of composites |

| Automotive | Engine components, customization | Faster prototyping, cost efficiency | Electric vehicle parts production |

| Medical | Surgical instruments, implants | Biocompatibility, precision manufacturing | Personalized medical devices |

| Electronics | Enclosures, circuit boards | Complex designs, rapid production | Miniaturization of components |

| Construction | Structural parts, fixtures | Durability, precise fit | Prefabrication trends |

Future Trends: Innovations in CNC Machining Technologies

The landscape of CNC machining is rapidly evolving, shaped by cutting-edge technologies that redefine production processes. Innovations such as artificial intelligence and robotics are increasingly being integrated into CNC systems, allowing for enhanced precision, reduced lead times, and the ability to handle complex tasks with minimal human intervention. This technological synergy not only improves efficiency but also significantly lowers operational costs, making manufacturing more competitive across various industries.

Moreover, the rise of digital manufacturing tools, including advanced simulation software and real-time data analytics, is set to revolutionize how manufacturers approach product design and fabrication. These technologies facilitate a more agile production environment, enabling manufacturers to quickly adapt to market demands and optimize their workflows. As we look towards 2025 and beyond, the aforementioned innovations will undoubtedly play a crucial role in shaping the future of machining, driving growth and sustainability within the manufacturing sector.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency