- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

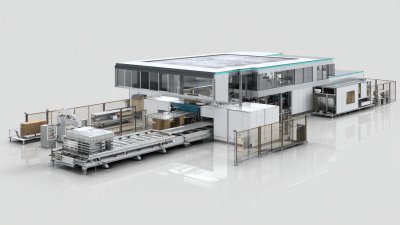

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

The manufacturing landscape is undergoing a significant transformation, driven by the advent of advanced technologies, particularly CNC machines. According to a report by MarketWatch, the global CNC machine market is projected to reach $100 billion by 2027, growing at a CAGR of 6.5%. This surge in demand reflects a broader industry trend towards automation and precision in production techniques.

CNC machines stand at the forefront of this revolution, enabling manufacturers to enhance efficiency, reduce production times, and achieve unparalleled accuracy in their processes. By automating complex tasks, these machines not only lower operational costs but also facilitate the customization of products, catering to the growing demand for bespoke manufacturing solutions. As industries strive to remain competitive, embracing CNC technology will be crucial for innovative production strategies and sustained growth in the manufacturing sector.

CNC machines stand at the forefront of this revolution, enabling manufacturers to enhance efficiency, reduce production times, and achieve unparalleled accuracy in their processes. By automating complex tasks, these machines not only lower operational costs but also facilitate the customization of products, catering to the growing demand for bespoke manufacturing solutions. As industries strive to remain competitive, embracing CNC technology will be crucial for innovative production strategies and sustained growth in the manufacturing sector.

Understanding CNC Technology: Principles and Benefits for Modern Manufacturing

CNC (Computer Numerical Control) technology represents a significant leap forward in modern manufacturing, providing unparalleled precision, efficiency, and flexibility. Unlike traditional manufacturing techniques, CNC machines utilize computer software to control machinery, which allows for accurate and repeatable production of complex parts. This automation minimizes human error and enhances the ability to produce intricate designs, enabling manufacturers to meet the growing demand for high-quality components across various industries.

The benefits of CNC technology extend beyond just precision. These machines can operate continuously, leading to increased production rates and lowered labor costs. Additionally, the programmability of CNC equipment allows for quick adjustments and modifications, empowering manufacturers to respond swiftly to market changes or custom orders. With the capability to work with a wide range of materials, including metals, plastics, and composites, CNC machines facilitate innovation, allowing companies to explore new product designs and applications that were previously challenging to achieve. Such advancements highlight the transformative role of CNC technology in shaping the future of manufacturing.

Integrating CNC Machines into Production Lines: Best Practices and Strategies

Integrating CNC machines into production lines requires a strategic approach to maximize efficiency and output. First, manufacturers should carefully assess their current workflows to identify areas where CNC technology can be seamlessly incorporated. This begins with selecting the right CNC machines that align with specific production needs, whether it’s for cutting, milling, or engraving.

Prioritize machines equipped with advanced features like automation and software compatibility to ensure they integrate well with existing systems.

Enhancing Precision and Efficiency: How CNC Machining Transforms Product Quality

CNC machining has emerged as a transformative force in the manufacturing sector, significantly enhancing precision and efficiency across various production processes. Unlike traditional methods, CNC (Computer Numerical Control) machines utilize computerized control to carry out manufacturing tasks with remarkable accuracy. This technology allows for intricate designs and tolerances that were once deemed impossible, minimizing the margin of error and ensuring that each product adheres to strict specifications. As a result, manufacturers can produce components that meet high-quality standards consistently, reducing waste and increasing the overall reliability of the final products.

Moreover, the automation provided by CNC machines streamlines production workflows, enabling manufacturers to respond swiftly to changing market demands. The ability to quickly switch between different tasks without the need for extensive retooling means that production can be more adaptable and efficient. With CNC technology, industries experience shorter lead times, and the reduction of manual labor translates into lower operational costs. This combination of enhanced precision and improved efficiency positions CNC machining as a pivotal element in the future of manufacturing, setting new benchmarks for product quality and operational excellence.

Exploring Advanced Software Solutions for CNC Machine Programming

Advanced software solutions for CNC machine programming are pivotal in the evolving landscape of manufacturing. These technologies empower operators to create precise and efficient designs, transforming traditional production methods. For instance, the integration of intuitive Computer-Aided Design (CAD) software streamlines the design process, allowing for detailed 3D modeling that enhances accuracy. As industries increasingly adopt automation, the role of comprehensive CAD/CAM systems becomes more critical, providing the necessary training for workers to adapt to these advanced tools.

Moreover, the push for innovation is evident in various sectors, such as medical machinery, where advanced software has enabled manufacturers to meet rising market demands with greater efficiency. For example, CNC programming solutions are now capable of significantly boosting production speeds while maintaining high precision levels. This transformative effect exemplifies how software not only supports CNC machines but also drives manufacturing forward, ensuring that companies remain competitive in a rapidly changing economic landscape. The rise of such technologies reflects a broader trend towards digital innovation, highlighting the importance of integrating cutting-edge software with manufacturing processes.

Exploring the Future of Manufacturing: CNC Machines and Production Techniques

The Future of CNC Manufacturing: Trends and Innovations to Watch Out For

The landscape of CNC manufacturing is evolving rapidly, driven by advancements in technology and shifting industry demands. As stated in recent market reports, the global CNC machine market is projected to expand significantly, influenced by the surge in demand for high-precision and efficient production processes across various sectors, including woodworking and furniture manufacturing. This shift towards automation and digital solutions presents opportunities for both small and medium enterprises (SMEs) and large corporations to enhance their operational efficiency.

Furthermore, the integration of smart technologies in CNC machinery is set to redefine production techniques. Innovations such as eco-friendly machines that reduce operational costs while meeting stringent environmental standards are becoming increasingly essential. The rise of intelligent manufacturing, highlighted by recent technological advancements in industrial automation, is a key trend that manufacturers should watch. As companies adopt automated solutions, the focus on lowering production costs and improving energy efficiency will shape the future of CNC manufacturing, making it imperative for industry players to stay ahead of these trends.

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

| Trend/Innovation | Description | Impact on Manufacturing | Expected Adoption Year |

|---|---|---|---|

| Artificial Intelligence Integration | Using AI algorithms for optimized CNC machining processes. | Increased efficiency and reduced production costs. | 2025 |

| Additive Manufacturing Techniques | Combining CNC with 3D printing methods. | Improved design flexibility and material efficiency. | 2024 |

| IoT Connectivity | Integration of IoT devices for remote monitoring of CNC machines. | Enhanced machine performance tracking and predictive maintenance. | 2026 |

| Sustainable Manufacturing Practices | Using CNC machines to produce sustainable products. | Reduced environmental impact and compliance with regulations. | 2023 |

| Advanced Materials | Incorporating new composite materials in CNC machining. | Improved product performance and durability. | 2025 |