- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Why You Should Consider a CNC Router for Your Next Project

In today's rapidly evolving landscape of manufacturing and craftsmanship, the CNC router has emerged as a game-changing tool that revolutionizes how projects are conceived and executed. As noted by industry expert John Smith, a prominent figure in CNC technology, "Investing in a CNC router opens up a world of possibilities for precision and creativity." This sentiment captures the essence of why integrating a CNC router into your toolkit can enhance both the quality and efficiency of your projects.

Whether you are a hobbyist looking to elevate your craft or a professional designer seeking to refine your production process, the versatility of a CNC router cannot be overstated. These machines allow for intricate designs, detailed carvings, and precise cuts, all while reducing the risk of human error. As technology continues to advance, the applications for CNC routers expand, catering to a wide array of industries including woodworking, metalworking, and even aerospace.

As you contemplate your next project, considering the adoption of a CNC router could be the turning point that propels your work to new heights. With the ability to leverage automation and precision, you can transform your creative visions into reality more efficiently than ever before.

Advantages of Using a CNC Router for Various Projects

CNC routers offer a multitude of advantages that make them an excellent choice for various projects across different industries. One of the primary benefits is their precision and consistency. Unlike manual machining, CNC routers operate using computer numerical control, allowing for intricate designs to be replicated with high accuracy. This makes them ideal for projects that require detailed and repetitive cuts, such as intricate signage, custom furniture, or architectural components. This level of precision not only enhances the quality of the final product but also reduces material waste, as the cuts are calculated to maximize the use of the raw materials.

Another significant advantage of using a CNC router is their versatility. These machines can work with a wide range of materials, including wood, plastics, composites, and even some metals. This versatility opens up endless possibilities for creativity and innovation, whether you are designing a unique art piece or fabricating parts for machinery. Additionally, CNC routers can be easily programmed to execute complex tasks that would be challenging or impossible with traditional equipment. This adaptability ensures that users can tackle diverse projects efficiently, making CNC routers a valuable asset in workshops, manufacturing plants, and creative spaces alike.

Key Features of CNC Routers to Consider

When considering a CNC router for your next project, it's crucial to evaluate key features that can significantly enhance your productivity and output quality. One of the most important aspects is the machine's cutting area. Many industry reports indicate that a larger cutting area allows for handling bigger projects without the need for multiple setups, which can streamline workflows and save time. For instance, a CNC router with a cutting area of at least 4'x8' can accommodate a wide variety of materials, from plywood to composite boards, making it versatile for various applications in woodworking and manufacturing.

Another critical feature to assess is the machine's spindle speed and power. According to research, CNC routers with higher spindle speeds (like 24,000 RPM) can cut through materials more efficiently, reducing the overall production time. Additionally, a powerful spindle provides the ability to work with a broader range of materials, enabling intricacy in designs and increased detail in finished products. Investing in a CNC router that balances spindle speed with consistent torque delivery can lead to enhanced precision and quality in your finished projects.

Finally, consider the software compatibility that comes with the router. The right software can streamline the design-to-production process, with industry statistics suggesting that up to 30% of time can be saved in project turnaround when utilizing integrated CAD/CAM systems. Modern CNC routers often feature compatibility with advanced software solutions, ensuring that operators can easily create complex designs and optimize cutting paths, significantly enhancing overall productivity and workflow efficiency.

Popular Applications of CNC Routers in Different Industries

CNC routers have revolutionized multiple industries by offering precision and efficiency in various applications. In the woodworking industry, CNC routers are widely used for creating intricate designs in cabinetry and furniture. According to a report by Technavio, the global woodworking CNC market is expected to grow by 11% annually over the next five years, driven by increased demand for custom furniture and cabinetry. These machines allow for complex cutting, engraving, and carving, making them indispensable for craftsmen looking to enhance their production capabilities.

In the signage and advertising sector, CNC routers are essential for producing high-quality signs with fine details. A study from Allied Market Research indicates that the digital signage market is projected to reach $31.71 billion by 2025, with CNC routers playing a key role in producing materials like acrylic, wood, and metal for various promotional displays. This technology enables businesses to create customized, eye-catching designs that effectively attract customers.

Tips: When selecting a CNC router for your projects, consider the machine's versatility and the types of materials it can handle. It's beneficial to invest in a router that offers a wide range of compatible materials to maximize your project options. Additionally, familiarity with CAD software will enhance your ability to design intricate patterns and optimize your workflow for better productivity.

Why You Should Consider a CNC Router for Your Next Project - Popular Applications of CNC Routers in Different Industries

| Industry | Popular Applications | Material Types | Benefits |

|---|---|---|---|

| Woodworking | Furniture making, cabinetry | Wood, MDF, plywood | Precision cuts, intricate designs |

| Manufacturing | Prototype development, part fabrication | Metals, plastics | Efficiency, reduced waste |

| Sign Making | Custom signs, logos | Acrylic, wood, aluminum | High customization, quick turnarounds |

| Arts and Crafts | Custom decorative items, sculptures | Wood, acrylic, foam | Creative freedom, intricate details |

| Architecture | Models, detailed components | Wood, plastic, composites | Precision, visual representation |

Comparing CNC Routers with Traditional Cutting Methods

When comparing CNC routers to traditional cutting methods, several key advantages emerge that make CNC technology a compelling choice for projects requiring precision and efficiency. Traditional cutting methods, such as manual saws or routers, often depend on the skill level of the operator, which can lead to inconsistencies in the final product. In contrast, CNC routers are programmed to execute designs with exactitude, resulting in uniform results regardless of the complexity of the project. This automation minimizes the variability associated with human error, ensuring each piece is crafted to the same specifications.

Additionally, the speed and efficiency of CNC routers provide significant benefits over traditional methods. Where manual cutting may require extensive setup and can be time-consuming, CNC routers streamline the process by allowing for rapid production and less labor-intensive operation. This efficiency not only speeds up project completion times but also opens up possibilities for more intricate designs that would be difficult to achieve manually. By leveraging advanced technology, CNC routers enable creators to push the boundaries of design and fulfill unique project demands with greater ease.

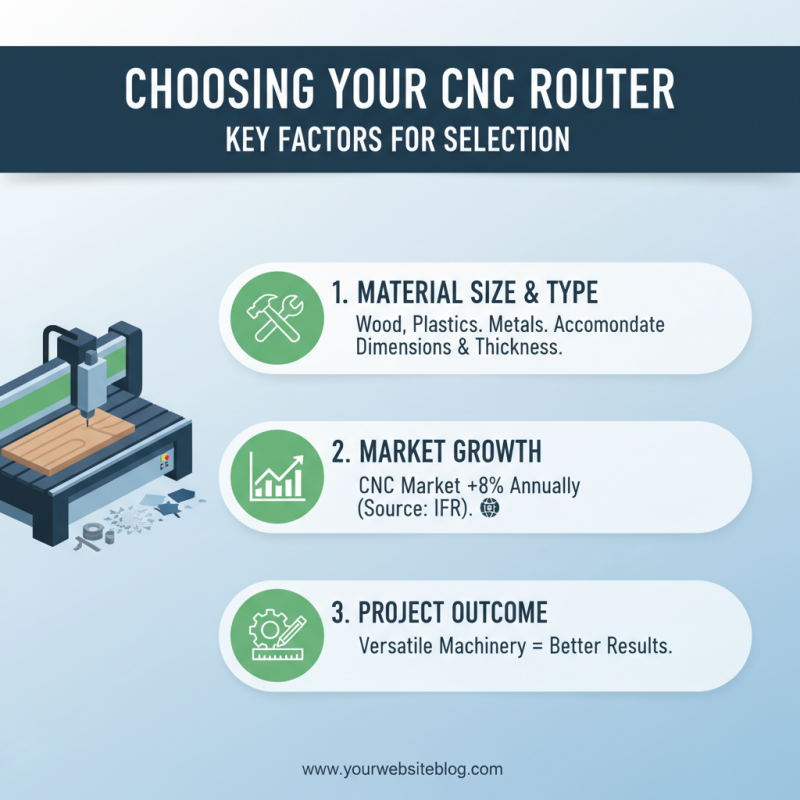

Tips for Choosing the Right CNC Router for Your Needs

When selecting the right CNC router for your needs, it's essential to consider several factors that can significantly impact the outcome of your projects. First, assess the size and type of materials you plan to work with. According to a report by the International Federation of Robotics, the CNC machining market is expected to grow by 8% annually, indicating a rising demand for versatile machinery that can handle various materials such as wood, plastics, and metals. Ensure that the CNC router you choose can accommodate the specific dimensions and thicknesses of the materials you intend to use.

Another critical aspect is the router's speed and precision. Advanced CNC routers can achieve cutting speeds exceeding 1,000 inches per minute, as indicated by market analysis from TechNavio. This capability is vital for maximizing efficiency and achieving high-quality finishes on your products. Additionally, look for models that offer high-resolution stepper motors or servo drives for improved accuracy, particularly for intricate designs or detailed carvings. Researching user reviews and manufacturer specifications can provide insights into the performance and reliability of different machines, guiding you to select a CNC router that aligns well with your project goals.

Related Posts

-

10 Essential Tips for Choosing the Right CNC Router for Your Projects

-

Best CNC Router Machine for Beginners and Professionals in 2023

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes