- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

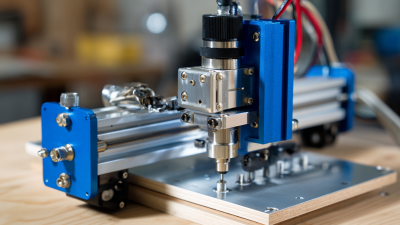

Top 10 CNC Router Machine Features You Should Know Before Buying

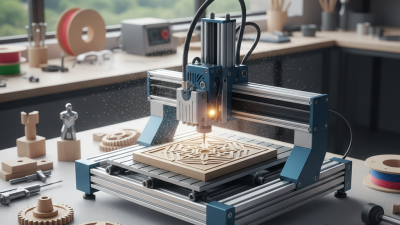

When considering the purchase of a CNC router machine, it is essential to be informed about the various features that can significantly impact your operational efficiency and overall results. As these machines have revolutionized the manufacturing and woodworking industries, understanding their capabilities and specifications will empower you to make an informed decision. In a landscape where precision and versatility are paramount, selecting the right CNC router machine can determine the success of your projects, whether you're a hobbyist or a professional.

In this guide, we will explore the top ten features that you should be aware of before making a purchase. From spindle power to software compatibility, each aspect plays a crucial role in the performance and utility of the CNC router machine. By delving into these features, you'll gain insights that not only enhance your understanding of the machine but also help you identify the best fit for your specific needs and applications.

Key Features of CNC Router Machines: A Comprehensive Overview

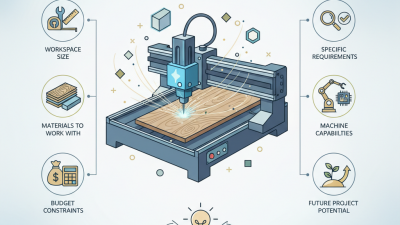

When considering the purchase of a CNC router machine, understanding its key features is crucial for making an informed decision. One of the most important aspects to consider is the machine's cutting area. The size of the work area will determine the maximum dimensions of the materials you can handle, impacting the projects you can undertake. Additionally, the machine's spindle speed and power are vital, as they directly affect the cutting efficiency and the ability to work with various materials, from softwoods to harder composites.

Another critical feature is the control system. A user-friendly interface and compatibility with different CAD/CAM software can significantly enhance the workflow. Moreover, look for machines that offer adjustable feed rates and cutting depths, allowing for greater versatility in your projects. Stability and build quality also play a vital role; a robust construction minimizes vibrations, leading to more precise cuts and a longer lifespan for the machine. Each of these features contributes to the overall performance and usability of the CNC router, making it essential to evaluate them carefully based on your specific needs and applications.

Top 10 CNC Router Machine Features You Should Know Before Buying

| Feature | Description | Importance |

|---|---|---|

| Spindle Power | Refers to the motor's capability to cut through various materials. | High |

| Work Area Size | The maximum dimensions of material that can be processed. | Medium |

| Control System | The software and hardware used to operate the CNC machine. | High |

| Material Compatibility | Ability of the router to handle different materials like wood, acrylic, and metals. | High |

| Precision and Accuracy | Degree to which the machine can perform tasks consistently. | High |

| Speed of Operation | Rate at which the CNC router can complete a task. | Medium |

| Ease of Use | How user-friendly the interface and controls are. | Medium |

| Durability | The longevity of the machine under regular use. | High |

| Cost | Overall price of the machine including features. | Medium |

| Support and Service | Availability of customer support and maintenance service. | High |

Understanding Different Types of CNC Router Machines and Their Applications

When considering a CNC router machine for your needs, it’s essential to understand the different types available and their specific applications. CNC routers come in various configurations, including wood routers, stone carving machines, and metal milling machines. Each type is engineered to handle unique materials and projects. For instance, wood routers are ideal for cabinetry and furniture making, while stone carving CNC machines excel in creating intricate designs for sculptures and countertops. Metal CNC routers are robust, designed for precision in machining metal components, making them invaluable in manufacturing and engineering sectors.

Tips: Assess your primary applications to determine the most suitable type of CNC router. For woodworking projects, focus on machines that can handle varying wood thicknesses and intricate designs. If you’re working with tougher materials like composites or metals, prioritize machines with a strong spindle and robust construction.

In addition to material compatibility, consider the machine's automation features, which can significantly improve efficiency. Advanced CNC routers offer programmable settings that allow for repeatable precision and speed, ideal for production runs. Investing in a machine with user-friendly software can enhance your productivity, especially if you're new to CNC machining.

Tips: Always test a machine's software interface before purchasing, as ease of use can greatly affect your workflow. Additionally, look for options that may offer online support and resources for troubleshooting, as this can be a valuable asset in maintaining your machine in the long run.

Essential Specifications: Speed, Power, and Precision in CNC Routers

When considering the purchase of a CNC router, understanding the essential specifications—speed, power, and precision—is crucial for achieving optimal results in your projects. Speed, typically measured in inches per minute (IPM), determines how quickly a router can move across materials. A higher speed can lead to increased productivity, allowing for more projects to be completed in a shorter amount of time. However, it's important to balance speed with the desired quality of the finished product, as excessive speed may compromise detail and accuracy.

Power is another critical specification in a CNC router, directly influencing the machine's capability to cut through different materials. Measured in horsepower or watts, a more powerful router can handle tougher materials and reduce the risk of motor strain. It's essential to assess the materials you'll be working with to ensure that the router's power aligns with your needs, particularly if you plan to use hardwoods or composites that require more robust equipment.

Lastly, precision is paramount in CNC machining. A precise router ensures that every cut is accurate, which is essential for maintaining tight tolerances and achieving high-quality finishes. Precision is often determined by the machine's components, including the drive system, bearings, and spindle. When evaluating a CNC router, consider the minimum tolerances it can achieve, as well as the overall build quality that contributes to consistent performance over time. Understanding these specifications will help you make an informed decision tailored to your specific applications.

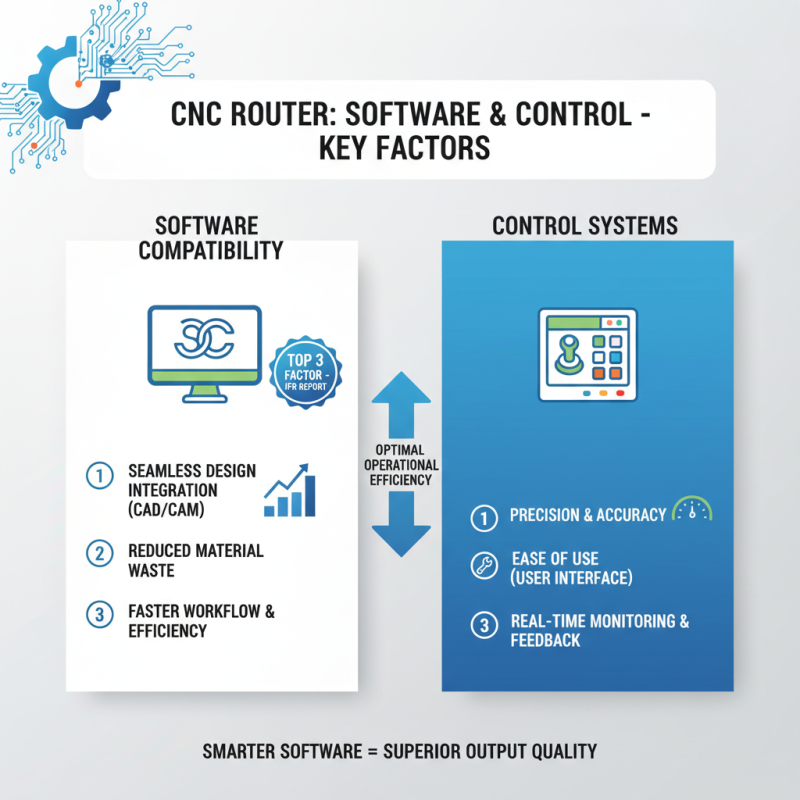

Evaluating Software Compatibility and Control Systems for CNC Routing

When considering a CNC router machine, software compatibility and control systems are crucial factors that can significantly impact operational efficiency and output quality. According to a recent industry report by the International Federation of Robotics, software compatibility is one of the top three aspects that professionals evaluate when selecting CNC machinery. A well-integrated software system allows for seamless design manipulation and precise execution of intricate patterns, ultimately saving time and reducing material waste.

Control systems play a vital role in enhancing the functionality of CNC routers. Advanced control systems enable users to execute complex tasks with high precision and consistency. Research from the Association for Manufacturing Technology indicates that machines equipped with intuitive control interfaces show a 25% increase in productivity compared to those with outdated systems. Moreover, understanding the compatibility of the software with various control mechanisms, such as G-code or proprietary systems, ensures that users can adapt their machines to different project needs, facilitating greater flexibility in production without compromising quality. As the CNC routing technology continues to evolve, prioritizing these elements can lead to significant advancements in workflow and operational outcomes.

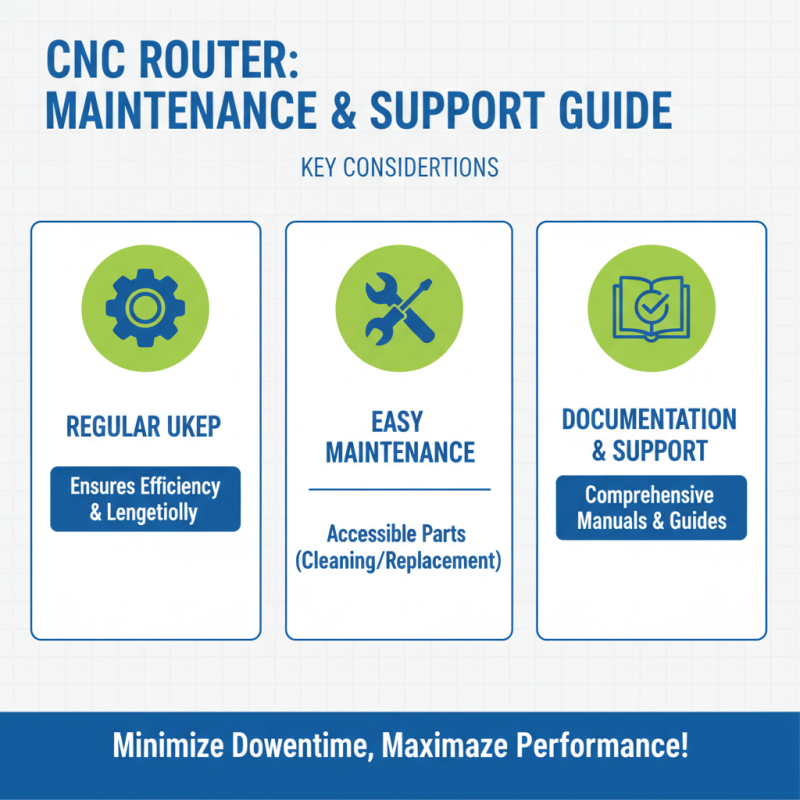

Maintenance and Support Considerations When Choosing a CNC Router

When selecting a CNC router, maintenance and support considerations are crucial aspects that should not be overlooked. Regular upkeep is essential to ensure your machine operates efficiently and lasts for years. Look for features that facilitate easy maintenance, such as accessible parts for cleaning and replacement. Machines with robust user manuals and maintenance guidelines can greatly assist users in performing routine checks and addressing minor issues before they escalate.

Additionally, the availability of customer support is paramount when making your purchase. Opt for manufacturers that offer comprehensive support, including troubleshooting services and technical assistance. Online resources such as tutorials, forums, and customer service hotlines can significantly enhance your experience and effectiveness in using the CNC router. A strong support network not only helps resolve immediate concerns but also contributes to the learning curve associated with operating such sophisticated machinery. Prioritizing maintenance and support in your decision-making process will lead to more satisfactory results and an enjoyable CNC routing experience.

Related Posts

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

10 Essential Tips for Choosing the Right CNC Router for Your Projects

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping