- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

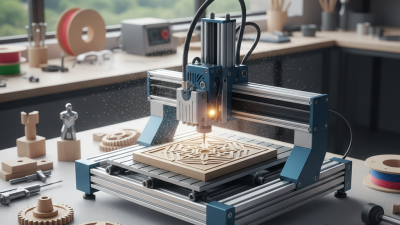

How to Choose the Best CNC Router Kit for Your Woodworking Projects

When embarking on woodworking projects, selecting the right CNC router kit can significantly impact the quality and efficiency of your work. According to John Smith, a well-respected expert in the CNC industry, “The key to successful woodworking lies in choosing the right tools, and a reliable CNC router kit can open up a world of creative possibilities.” This statement highlights the essential role that a CNC router kit plays in transforming intricate designs from ideas into tangible creations.

In the current market, there is a wide variety of CNC router kits available, each with different features and specifications. Understanding which kit best suits your specific needs requires careful consideration of factors such as the size of your projects, the materials you'll be using, and your level of expertise. The right CNC router kit should not only align with your woodworking goals but also enhance your skillset, empowering you to take on more complex tasks and achieve professional-quality results.

As you delve into the process of selecting the ideal CNC router kit, it’s crucial to assess your individual requirements meticulously. By doing so, you can ensure that your investment translates into a worthwhile addition to your woodworking arsenal, allowing for precision, creativity, and satisfaction in every project you undertake.

Understanding Your Woodworking Needs and Goals

When selecting the best CNC router kit for your woodworking projects, it is essential to first understand your specific needs and goals. Different projects require various functionalities, so start by evaluating what types of woodwork you intend to pursue. For instance, if your plans involve intricate designs or detailed carvings, you might prioritize a machine with greater precision and versatility. On the other hand, if you are mainly focusing on simpler cuts or larger pieces, a standard model may suffice. Additionally, consider the scale of your projects; a hobbyist might not require the same capabilities as a professional woodworker handling larger productions.

Next, think about the materials you plan to use and their compatibility with potential CNC router kits. While wood is the primary choice, many projects incorporate composite materials or even plastics. Your router should be able to handle the range of materials you’re interested in. Understanding your woodworking goals extends to recognizing your skill level too; a beginner may prefer a more user-friendly kit with straightforward setup and operation, whereas an experienced woodworker might opt for advanced features that offer greater control and customizability. Balancing these factors will ultimately guide you in choosing the CNC router kit that best fits your woodworking aspirations.

How to Choose the Best CNC Router Kit for Your Woodworking Projects

| Feature | Description | Importance Level |

|---|---|---|

| Cutting Area | The maximum size of material the CNC router can handle. | High |

| Motor Power | The strength of the motor which affects cutting speed and material types. | High |

| Software Compatibility | The types of design software it can work with. | Medium |

| Build Quality | Material and construction quality of the CNC router. | High |

| Ease of Assembly | How straightforward the setup process is. | Medium |

| Support and Resources | Availability of customer support and tutorials. | Medium |

| Price | The cost of the CNC router kit. | High |

Key Features to Consider in CNC Router Kits

When selecting a CNC router kit for woodworking projects, it's essential to consider several key features that can significantly affect performance and usability. One of the crucial aspects is the machine's cutting area. According to a report by Technavio, the growing interest in customized woodworking solutions has increased the demand for CNC routers with larger cutting capabilities, allowing artisans more flexibility in their projects. Look for kits that provide a generous work envelope, ideally at least 24"x24" or larger, to accommodate a diverse range of materials and designs.

Another important feature to evaluate is the machine's spindle power and speed. Spindle power, usually measured in watts or horsepower, directly impacts the type and thickness of materials you can work with. A higher-speed spindle can allow for finer details and faster production times. A recent survey conducted by the Wood Products Manufacturers Association indicated that hobbyists and professionals who prioritize speed and efficiency often prefer routers with spindle speeds of around 24,000 to 60,000 RPM.

**Tips:** When choosing a CNC router kit, always check for software compatibility as it plays a critical role in your overall experience. Additionally, consider the ease of assembly and customer support options, as these can save you time and frustration during setup and operation. Lastly, invest in a model with strong community support or online resources; this can be invaluable for troubleshooting and maximizing the use of your CNC router.

Assessing Size and Workspace Requirements

When selecting the best CNC router kit for your woodworking projects, assessing size and workspace requirements is crucial. The size of the router will dictate not only the scale of the projects you can undertake but also the space you need to accommodate your equipment. Begin by evaluating the dimensions of your workshop or designated workspace. Ensure you measure both the available floor space and the vertical clearance, as some CNC routers may require overhead space for materials and movement.

Once you have a clear understanding of your workspace, consider the types of projects you wish to create. Larger projects, such as furniture or intricate cabinetry, often require a router with a bigger cutting area. Conversely, if you are focused on smaller items, a more compact router may suffice. Additionally, think about the materials you will be using—thicker or denser woods may necessitate a more robust machine with greater power and stability. By aligning the router's size and capabilities with your specific project needs and available space, you ensure a more efficient and enjoyable woodworking experience.

Evaluating Software Compatibility and Ease of Use

When selecting a CNC router kit for woodworking projects, software compatibility and ease of use are crucial factors to consider. The software serves as the heart of the CNC system, allowing you to create, edit, and control designs. It's essential to choose a kit that supports user-friendly software programs, ensuring that even beginners can navigate the design process without overwhelming complexity. Look for software that offers intuitive interfaces and clear instructions, allowing users to focus on creativity rather than grappling with technical difficulties.

Moreover, compatibility with various operating systems and file formats can significantly enhance your experience. Make sure the CNC router kit supports software that can seamlessly integrate with popular design applications, allowing for smooth transitions from digital concept to physical creation. Software that provides comprehensive tutorials and community support can also be a great advantage, as they can help users quickly solve issues and harness the full potential of their CNC router. Ultimately, prioritizing software compatibility and usability will help ensure that your woodworking projects are enjoyable and efficient from the start.

How to Choose the Best CNC Router Kit for Your Woodworking Projects

Budgeting for Your CNC Router Kit Investment

When considering the investment in a CNC router kit for woodworking projects, budgeting is a crucial factor that can significantly influence the choice and long-term satisfaction with the equipment. According to a 2022 report by Grand View Research, the global CNC machine market is expected to reach USD 117.1 billion by 2028, showcasing a robust growth trend driven by increased automation and demand for precision tools. This growth reflects the importance of investing in quality tools that can deliver consistent results, particularly for serious woodworking enthusiasts or small businesses.

Typically, the price range for CNC router kits varies widely based on specifications and features. An entry-level kit may cost anywhere from USD 500 to USD 1,500, while professional-grade models can exceed USD 5,000. The key is to assess your needs and potential return on investment. According to a survey conducted by the Woodworking Network, nearly 40% of woodworking professionals reported that investing in higher-quality machinery directly improved their productivity and project outcomes. Therefore, it’s essential to align budget constraints with the features necessary for your woodworking projects, ensuring that your investment yields both performance and longevity.

Related Posts

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

Top 10 CNC Router Machine Features You Should Know Before Buying

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Why You Should Consider a CNC Router for Your Next Project