- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

The 10 Best Woodworking Machinery Tools You Need for Your Workshop

In the realm of woodworking, having the right machinery is essential for both beginners and seasoned professionals. As woodworking machinery expert David Marks once said, "The right tools can turn an ordinary piece of wood into a work of art." This underscores the importance of selecting the best tools for your workshop, not only to enhance creativity but also to improve efficiency and precision in woodworking projects.

The landscape of woodworking machinery offers a plethora of options, each serving a specific purpose. From saws that slice through lumber with ease to planers that create smooth surfaces, the choice of tools can significantly impact the quality and outcome of your creations. As you set up your workshop, understanding which machinery is essential can lead to a transformative experience, allowing both amateurs and experts alike to push the boundaries of their craft.

In this guide, we will explore the ten best woodworking machinery tools that every workshop should consider. These tools not only streamline processes but also elevate the craftsmanship that goes into every wooden piece. Join us as we delve into a selection that promises to equip your workshop with the tools needed to bring your woodworking visions to life.

Essential Woodworking Machinery for Every Workshop

In any woodworking workshop, certain machinery tools stand out as essential for achieving precision and efficiency. According to a report by the Woodworking Machinery Manufacturers of America (WMMA), the use of advanced woodworking machinery can enhance productivity by up to 30%, significantly reducing labor time while improving the quality of the finished products. The most crucial tools include table saws, band saws, and jointers, which provide the foundational capabilities for cutting, shaping, and joining wood effectively.

Furthermore, investing in modern woodworking machinery not only boosts efficiency but also promotes safety in the workshop. Statistics show that shops equipped with proper machinery and safety features have reported a decrease in workplace injuries by nearly 40%. Tools such as dust collectors and router tables help mitigate health risks associated with wood dust and improve the overall working environment. As woodworking continues to evolve, equipping workshops with these essential machines is paramount for both hobbyists and professionals looking to create high-quality pieces with greater ease and safety.

The 10 Best Woodworking Machinery Tools You Need for Your Workshop

Key Features to Look for in Woodworking Tools

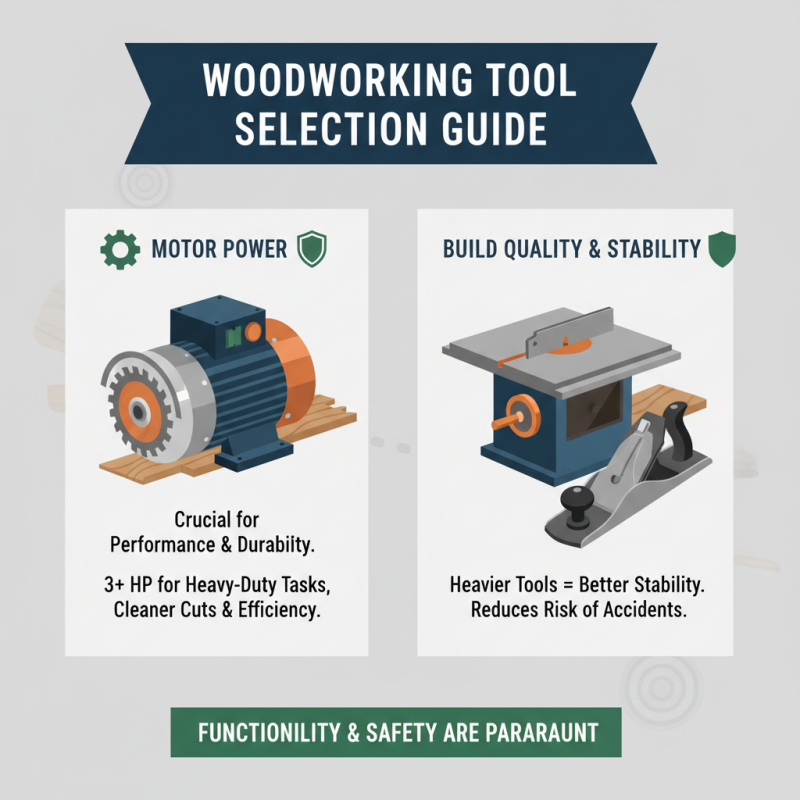

When selecting woodworking tools for your workshop, understanding the key features that enhance functionality and safety is paramount. One of the most critical aspects is the motor power. A robust motor not only dictates the tool's performance but also its durability over time. Industry research indicates that tools with motors exceeding 3 horsepower are optimal for heavy-duty tasks, allowing for cleaner cuts and improved efficiency. Additionally, consider the weight and build of the tools; heavier models tend to provide better stability during operations, reducing the risk of accidents.

Another essential feature to look for is the safety mechanisms incorporated into woodworking tools. According to a report by the National Institute for Occupational Safety and Health, more than 50% of woodworking-related injuries are preventable with the use of proper safety features such as blade guards, emergency shut-off switches, and kickback protection. Ergonomics also plays a significant role in tool design; tools equipped with comfortable grips and adjustable settings can significantly reduce user fatigue and enhance precision, ultimately leading to higher quality craftsmanship. Investing in tools that prioritize these features not only boosts productivity but also ensures a safer woodworking environment.

Top 10 Must-Have Woodworking Machines Explained

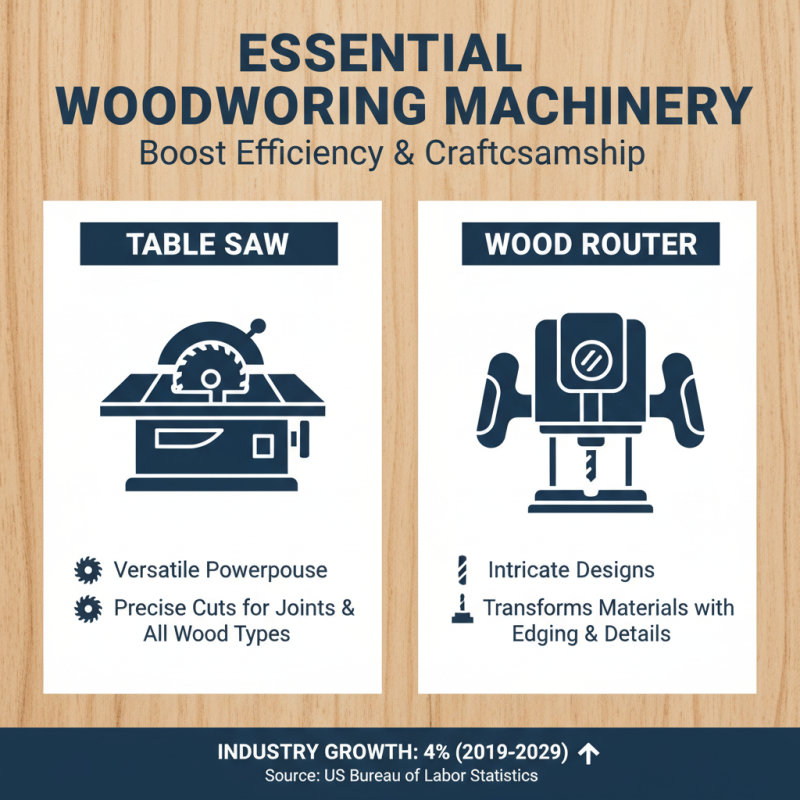

When setting up a woodworking workshop, the choice of machinery is critical to both efficiency and craftsmanship. According to the U.S. Bureau of Labor Statistics, the woodworking industry is projected to grow by 4% from 2019 to 2029, highlighting the increasing demand for skilled craftspeople equipped with the right tools. Among the essential machines, the table saw stands out as a versatile powerhouse, enabling precise cuts for all types of wood and ensuring seamless joint creation. Furthermore, a router can add intricate designs and edging, transforming basic materials into masterpiece creations.

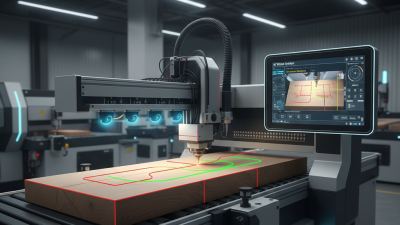

In addition, a thickness planer is indispensable for achieving uniform board thickness, which significantly improves the quality of the final product. The Woodworking Machinery Manufacturers of America reports that as more hobbyists and professionals alike embrace CNC technology, a CNC router has become an essential tool for intricate design and rapid prototyping. These machines not only streamline production but also allow artisans to explore their creativity without the limitations of manual techniques. Investing in these top woodworking machines ultimately leads to enhanced productivity and quality, ensuring that any workshop can thrive in an increasingly competitive environment.

Safety Considerations When Using Woodworking Machinery

When working with woodworking machinery, safety should always be the top priority. The use of proper personal protective equipment (PPE) is essential to prevent injuries. Wearing safety goggles can protect your eyes from sawdust and flying debris, while ear protection is crucial to shield your hearing from loud machinery noises. Additionally, durable gloves can help prevent cuts and abrasions when handling wood and tools, although care should be taken to avoid loose-fitting gloves that could get caught in moving parts.

Furthermore, maintaining a clean and organized workspace significantly reduces the risk of accidents. Keeping the floor free of sawdust and debris can prevent slips and falls. It’s important to familiarize yourself with the machinery’s operating manual before use, ensuring that you understand all safety features and emergency shut-off methods. Regular maintenance checks on tools to ensure they are in safe operating condition is also vital. Being aware of surroundings and avoiding distractions while using machinery helps maintain focus and enhances safety.

The 10 Best Woodworking Machinery Tools You Need for Your Workshop - Safety Considerations When Using Woodworking Machinery

| Tool Name | Primary Use | Safety Considerations | Recommended Safety Gear |

|---|---|---|---|

| Table Saw | Cutting large pieces of wood | Risk of kickback and serious cuts | Safety goggles, hearing protection, push stick |

| Band Saw | Curved cuts and resawing | Avoid loose clothing near blades | Safety glasses, dust mask |

| Jointer | Flattening wood surfaces | Hands near blades can cause injury | Face shield, ear protection |

| Planer | Thicknessing wood | Risk of entanglement | Safety goggles, gloves |

| Router | Cutting decorative edges | Flying debris and cuts | Safety glasses, ear protection |

| Scroll Saw | Intricate cuts and designs | Hands near blades | Safety glasses, dust mask |

| Miter Saw | Crosscuts and angled cuts | Risk of misalignment and kickback | Safety eyewear, gloves |

| Drill Press | Drilling precise holes | Risk of binding and spinning | Safety goggles, dust mask |

| CNC Router | Automated cutting and shaping | Electrical hazards and tool engagement | Safety glasses, hearing protection |

Maintenance Tips for Longevity of Your Workshop Tools

Maintaining woodworking tools is crucial for longevity and performance in any workshop. According to a report by the American National Standards Institute, poorly maintained machinery can lead to a 30% decrease in efficiency and productivity. This emphasizes the importance of regular maintenance to ensure that your tools not only perform optimally but also last longer, reducing the need for costly replacements. Simple tasks such as cleaning, lubricating moving parts, and inspecting for wear can significantly extend the lifespan of your tools.

In addition, a study by the National Wood Flooring Association highlights that well-maintained equipment operates safer, reducing the risk of accidents by up to 50%. Implementing a regular maintenance schedule is key; for instance, scheduling cleaning after every major project and conducting a thorough inspection monthly can help catch potential issues early. Furthermore, storing tools properly and protecting them from moisture can prevent rust and damage, according to the Wood Products Council. By focusing on proactive care for your woodworking tools, you're not only enhancing their efficiency but also ensuring a safer working environment.

Related Posts

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Why Choose a Rotary Screw Air Compressor for Your Industrial Needs?