- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2026 Best CNC Wood Carving Machine for Precision and Creativity?

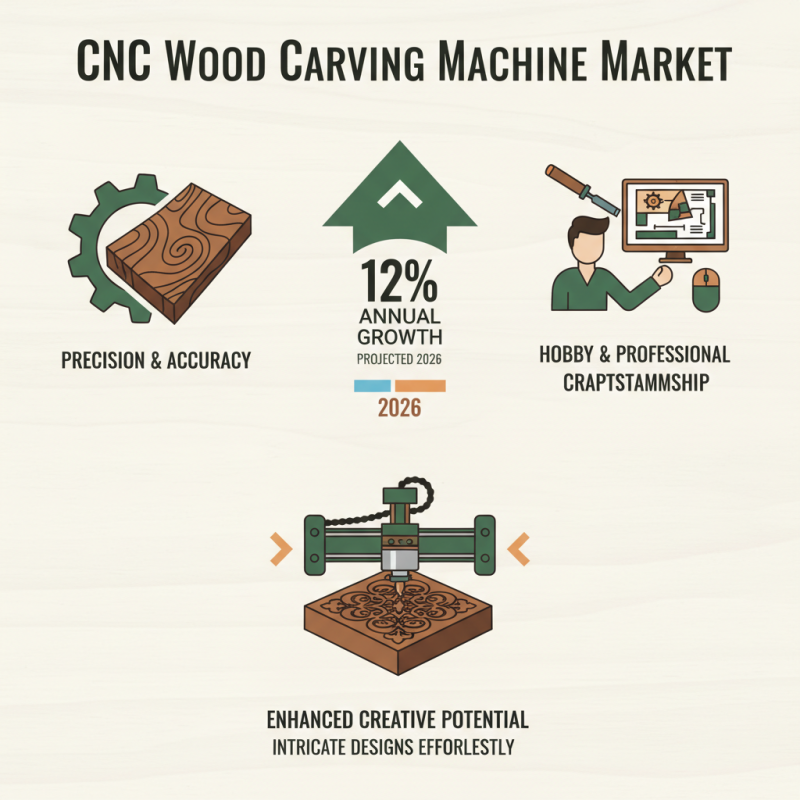

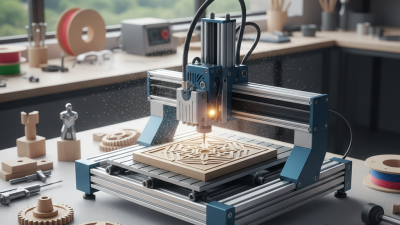

In recent years, the demand for CNC wood carving machines has surged. According to a market research report by Grand View Research, the CNC machine market is expected to reach $117 billion by 2025. This growth highlights a trend towards precision and creativity in woodworking. As artisans seek to enhance their craftsmanship, they turn to advanced technology to achieve intricate designs.

CNC wood carving machines offer unmatched precision. They enable users to carve complex patterns with ease and accuracy. For example, a machine can replicate detailed designs that would take hours by hand. However, the initial investment can be a barrier for many small businesses. These machines require a learning curve, which can be frustrating. Not every carving turns out perfect, necessitating practice and patience.

The embrace of technology in woodworking reflects broader industry shifts. Creative professionals are not just using CNC machines for efficiency; they seek artistic expression. While the benefits are clear, challenges remain. Users must balance creativity with the technical aspects of CNC operation. This blend creates room for innovation and exploration in the craft.

Understanding CNC Wood Carving Machines: An Overview of Technology

CNC wood carving machines have revolutionized the woodworking industry. They offer precision that traditional methods struggle to achieve. According to a recent industry report, the CNC machine market is projected to reach $7 billion by 2026. This rapid growth shows how essential these machines have become.

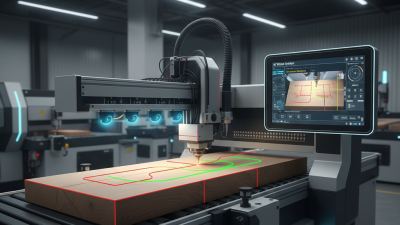

These machines use computer-controlled designs to carve intricate patterns. A high-quality CNC wood carving machine can achieve tolerances as tight as 0.01 mm. This level of detail is important for artisans and manufacturers alike. However, the technology is not without its challenges. Programming the machine can be complex. Mistakes in the design phase can lead to wasted materials and time.

Moreover, the initial investment can be significant. Many small businesses may hesitate to adopt CNC technology. They fear it might not pay off. Yet, companies that embrace this innovation often report increased efficiency. Research indicates a 30% reduction in production time when using CNC machining. While the benefits are evident, the path to mastering CNC technology may require ongoing training and adaptation.

2026 Best CNC Wood Carving Machine for Precision and Creativity

| Model | Max Cutting Area (mm) | Spindle Power (W) | Precision (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| CNC Carver Pro X1 | 600 x 400 | 1500 | 0.01 | 35 | 1200 |

| WoodMaster 5000 | 800 x 600 | 2000 | 0.02 | 50 | 1650 |

| ProCarve Elite 3000 | 1000 x 800 | 2500 | 0.005 | 65 | 2200 |

| CNC Wood Pro X2 | 1200 x 900 | 3000 | 0.015 | 75 | 3500 |

| CarveXpert 2000 | 750 x 500 | 1800 | 0.03 | 40 | 1400 |

Key Features to Consider When Selecting a CNC Wood Carving Machine

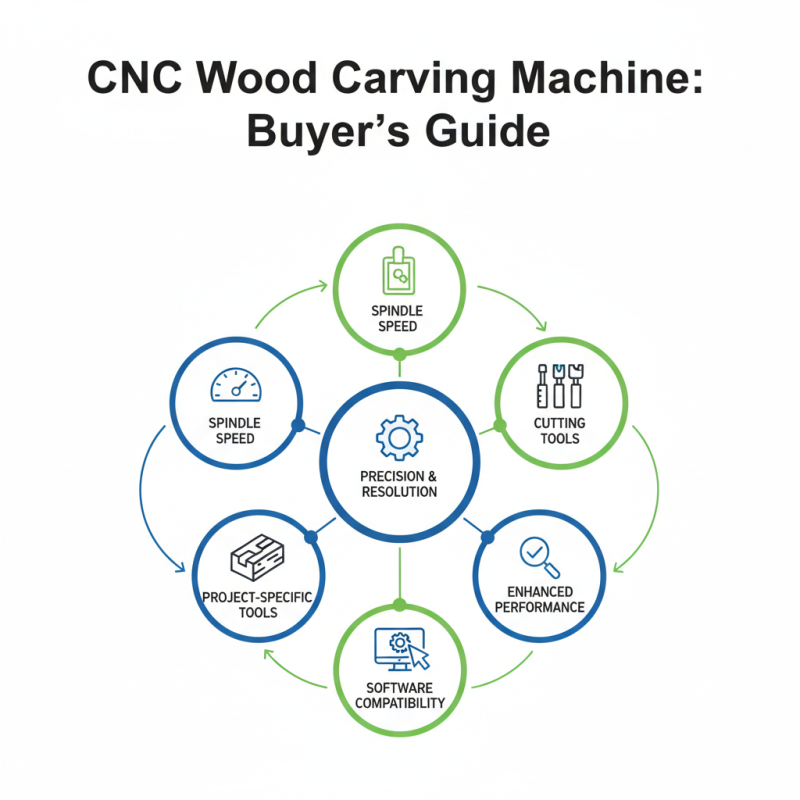

When selecting a CNC wood carving machine, precision is crucial. Look for machines that offer high-resolution capabilities. A good spindle speed can enhance performance. Many machines come with various cutting tools. Choose tools that fit your specific projects. It's essential to consider the machine's compatibility with different software.

Creativity is another critical aspect. Some machines provide advanced features like 3D carving functions. They can create intricate designs that add depth and character. Explore models that offer a range of size options. This flexibility lets you work on small detailed pieces or larger projects. Ensure that the machine can handle various materials too, from softwoods to hardwoods.

Lastly, consider user support and community. A machine with a supportive user base can be invaluable. You might face challenges during your creative process. Tutorials and forums can help you overcome hurdles. Don't overlook the importance of maintenance, either. Regular upkeep is necessary for longevity and performance. Remember, a well-cared-for machine can be both a reliable tool and a creative partner.

Comparative Analysis of Top CNC Wood Carving Machines for 2026

In 2026, the CNC wood carving machine market is projected to grow by 12% annually. This growth reflects the rising interest in woodworking as both a hobby and professional craftsmanship. Precision is key in this field. Machines that deliver high accuracy can significantly enhance creative potential. Users seek tools that can handle intricate designs effortlessly.

Data from industry reports show that today's machines offer a variety of advanced features. Some models include automatic tool changers and enhanced software compatibility. However, not all devices meet the desired precision levels. This can lead to underwhelming results in complex projects. Users often report frustration with machines that falter on delicate engravings.

It's important to consider the learning curve associated with new technology. A machine might have great specifications, but if it’s difficult to use, it may not deliver the expected creativity boost. Many users find themselves contemplating if the investment aligns with their skill level and project demands. Understanding these intricacies is vital in making informed decisions. Balancing precision with creativity continues to be a pressing challenge for woodworkers.

Application of CNC Wood Carving in Creative Projects and Industries

CNC wood carving technology has transformed creative projects across various industries. This innovation allows artisans to achieve intricate designs with unparalleled precision. According to recent industry reports, the global CNC wood carving market is projected to grow by 10% annually. The increasing demand for bespoke wood products fuels this expansion.

In creative sectors, CNC machines enhance productivity. They can produce complex patterns that would be nearly impossible to achieve by hand. For instance, in furniture design, these machines can carve detailed motifs on tabletops. However, it's worth noting that reliance on CNC technology can reduce the artisanal touch. Some craftsmen worry about losing traditional skills.

Moreover, the application of CNC wood carving in industries like architecture and signage provides exceptional detail and reliability. Studies show that businesses using CNC machines often report a 30% increase in efficiency. Yet, as industries evolve, there’s a growing debate about the balance between technology and creativity. Can machines truly capture the essence of artistic expression? This remains a critical question for many in the field.

2026 Best CNC Wood Carving Machine for Precision and Creativity

This chart displays key performance metrics for CNC wood carving machines as of 2026, including accuracy, speed, versatility in project types, and ease of use ratings. These attributes are crucial for precision and creativity in wood carving applications.

Maintaining Precision: Tips for Using CNC Wood Carving Machines Effectively

CNC wood carving machines are powerful tools for creatives. However, achieving precision requires more than just owning one. Reports indicate that up to 30% of woodworkers face challenges due to improper machine calibration. Regular calibration is crucial for maintaining accuracy. Regular checks can prevent costly errors during projects.

Understanding your material is also essential. Different woods behave uniquely. For instance, hardwoods can cause more wear on bits compared to softwoods. This wears down tools faster and affects carvings. Many users overlook tool maintenance. Dull bits can lead to rough edges and inaccuracies. It's advisable to change bits regularly, based on usage.

Lastly, proper feed rates affect precision. A study suggests that feed rates that are too high can lead to missed cuts. Slow and steady often leads to cleaner results. Take the time to adjust parameters for each project. Patience is a virtue when it comes to CNC machining. These small adjustments can drastically improve creative outcomes. Ignoring this can lead to frustration and wasted materials.

Related Posts

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

How to Choose the Best CNC Router Kit for Your Woodworking Projects

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

Top 10 CNC Router Machine Features You Should Know Before Buying