- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

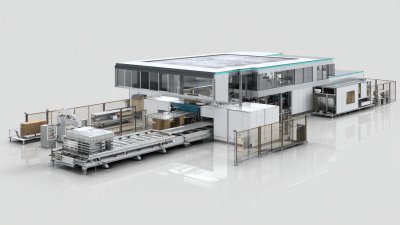

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

The Best CNC Mill Types for Your Machining Needs?

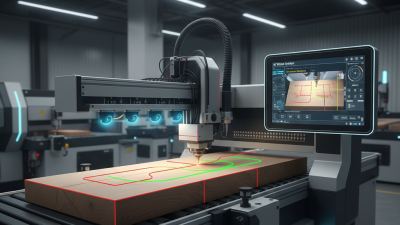

Choosing the right CNC mill can transform your machining process. The diversity of CNC mills available today makes selection challenging. Specific needs, such as material type and part complexity, should guide your choice.

Different CNC mills offer unique advantages. Some are better suited for high-precision tasks, while others excel in speed. This variety can create confusion for beginners. Understanding your project requirements is crucial to making the right decision.

Consider your budget and intended use carefully. Investing in a more advanced CNC mill may pay off in the long run. However, you might find that simpler models suffice for your needs. Reflect on your capabilities and project goals before making a final choice.

Understanding CNC Milling Machines: Types and Applications

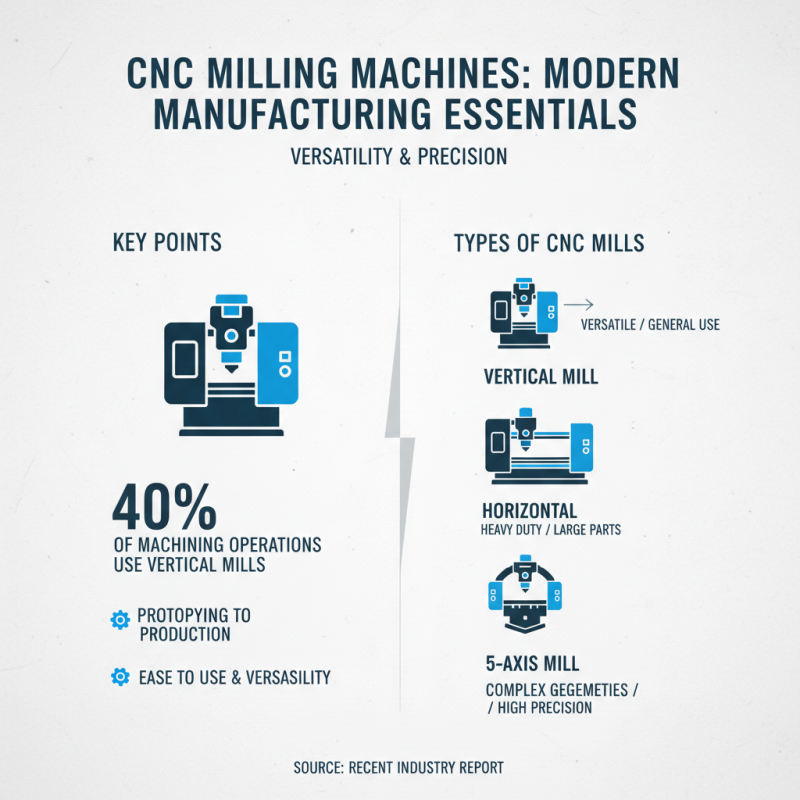

CNC milling machines are essential in modern manufacturing. They come in various types, each suited for specific applications. For example, vertical CNC mills are popular for their versatility and ease of use. According to a recent industry report, over 40% of machining operations utilize vertical mills for tasks ranging from prototyping to large-scale production.

Horizontal CNC mills, while less common, offer unique advantages. They excel in heavy-duty tasks and complex geometries. Data shows that businesses using horizontal mills often experience a 20% increase in operational efficiency. However, these machines require higher initial investment and maintenance costs. The decision to choose a CNC mill type hinges on the complexity of the projects and budget constraints.

**Tips:** Consider implementing usage simulations before purchase. This allows for a better understanding of the capabilities. Always assess the volume and type of materials you’ll be working with. Keep in mind that some machines might not handle every material type seamlessly. Reflect on your specific machining needs to avoid costly mistakes.

Key Factors to Consider When Choosing a CNC Mill

When selecting a CNC mill, several key factors emerge. These factors greatly influence the efficiency and outcomes of machining projects. One vital consideration is the type of materials being processed. Harder materials often require more robust machines. A study from the International Journal of Advanced Manufacturing Technology suggests that around 70% of machining issues stem from material compatibility.

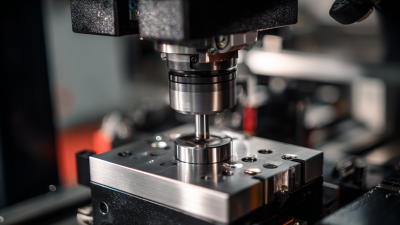

Another important factor is precision. CNC mills vary in accuracy and repeatability. For high-end projects, a precision of ±0.005 inches is often expected. It's crucial to analyze the specifications of the mill, ensuring they align with project needs.

**Tips:**

Always assess your workflow. If you’re frequently changing materials or designs, flexibility in your CNC mill is necessary.

Regular maintenance is essential for longevity and performance. Faulty machines can lead to increased costs and waste.

Understand your team's capability. A complex CNC mill may require specialized training, impacting productivity.

Take time to evaluate the long-term benefits of each mill type. Investing in advanced features could save you money in the future. Balancing budget constraints with expected outcomes can be challenging, yet it's necessary for sustainable growth.

The Best CNC Mill Types for Your Machining Needs

| CNC Mill Type | Best For | Axis Configuration | Preferred Industries | Price Range ($) |

|---|---|---|---|---|

| Vertical CNC Mill | General Purpose Machining | 3-Axis | Aerospace, Automotive | 15,000 - 50,000 |

| Horizontal CNC Mill | High Volume Production | 3-Axis | Heavy Industry, Manufacturing | 30,000 - 100,000 |

| 5-Axis CNC Mill | Complex Geometries | 5-Axis | Medical, Aerospace | 50,000 - 150,000 |

| CNC Router | Sign Making, Woodworking | 3-Axis | Furniture, Decorative Items | 5,000 - 30,000 |

| Desktop CNC Mill | Hobby Projects, Prototyping | 3-Axis | Crafting, Small Parts | 1,000 - 5,000 |

Comparative Analysis of Vertical vs. Horizontal CNC Mills

When choosing between vertical and horizontal CNC mills, it's essential to analyze their unique features and production capabilities.

Vertical CNC mills are often more accessible, especially for smaller projects. They are ideal for tasks that require precise and intricate cuts.

According to industry reports, about 70% of small businesses prefer vertical mills due to their lower initial investment and ease of use.

In contrast, horizontal CNC mills excel in high-volume production.

They can accommodate larger workpieces and allow for multiple setups without frequent retooling.

Reports show that horizontal mills can be 30% more efficient for certain tasks when compared to their vertical counterparts.

However, their complexity may deter some users, particularly those new to CNC machining.

A reflection on the choice between these two types reveals that both have strengths and weaknesses.

Users often overlook maintenance costs and training needs. Vertical mills may require less training, yet their capabilities can fall short for complex tasks.

Horizontal mills offer versatility but include a steep learning curve. Ultimately, the decision hinges on individual production needs and skill levels.

Specialty CNC Mills: Benefits and Use Cases

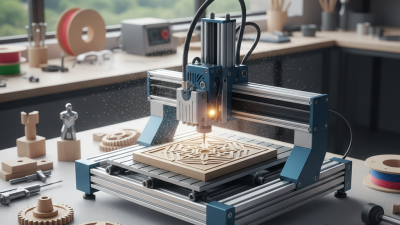

Specialty CNC mills offer unique features that meet diverse machining needs. These mills excel in tasks like engraving, 3D milling, or large-scale production. Their design often includes additional customization options. This flexibility can lead to improved efficiency. However, choosing the right one may be challenging.

For instance, a dedicated engraving mill focuses on intricate designs. It’s ideal for jewelry and signage. Conversely, a high-speed CNC mill is perfect for complex shapes. It may improve turnaround time but requires skilled operators. Each type has its pros and cons.

Unexpected issues can arise. Maintenance may be complex due to specialized parts. Training staff for specific operations can be a hassle. Consider these factors when selecting a specialty CNC mill. Making the right choice is crucial for successful machining.

The Best CNC Mill Types for Your Machining Needs

Cost Considerations and Maintenance for CNC Mills

When considering CNC mills, cost plays a significant role. Initial purchase prices can vary greatly. The range typically lies between $5,000 to $100,000, depending on the machine's capabilities. A study from the Association for Manufacturing Technology indicates that approximately 30% of manufacturers cite high upfront costs as a barrier to adopting advanced CNC technology.

Beyond initial costs, maintenance is crucial for operational efficiency. Regular maintenance can prevent expensive downtime. A well-maintained CNC mill can last over 10 years, but neglect can shorten this lifespan drastically. According to a report by IndustryWeek, manufacturers who prioritize maintenance see a 20% increase in equipment lifespan. This statistic highlights the importance of investing time and resources in regular checks and balances for your CNC machinery.

Budgeting for unexpected repairs is also vital. It is suggested to allocate at least 5% of the total equipment cost annually. This amount helps when unexpected issues arise. Many businesses overlook this, ultimately leading to financial strain. Reflecting on the balance between upfront costs and long-term savings can help businesses make sustainable choices.

Related Posts

-

2026 How to Choose the Right CNC Mill for Your Workshop Needs?

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency