- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

In the rapidly evolving world of woodworking machinery, innovation is the key to staying ahead. As we look towards 2025, industry experts are anticipating groundbreaking advancements that will redefine efficiency and precision in woodworking processes. Renowned woodworking machinery expert, John Anderson, remarked, “Embracing new technologies in woodworking machinery not only enhances production but also elevates the craftsmanship to new heights.”

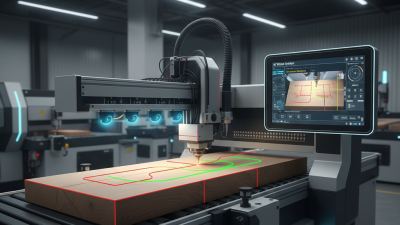

This year, we will explore the top ten innovations that every woodworking professional should keep an eye on. From automated cutting systems to advanced CNC technology, these breakthroughs promise to revolutionize how woodworkers design, create, and manufacture their products. As we venture into this exciting landscape, it is essential to understand the impact of these innovations on the industry and how they can help artisans and manufacturers alike to achieve unparalleled results in their projects.

Join us as we delve deeper into the top five transformative woodworking machinery innovations of 2025 and discover the future of woodworking that awaits us. The right tools coupled with the latest technologies will empower craftsmen and businesses, ultimately leading to a more efficient and creative woodworking environment.

Emerging Trends in Woodworking Machinery for 2025

As we look forward to the woodworking machinery landscape in 2025, several emerging trends signal a significant transformation in the industry. The integration of smart technology is at the forefront, with many manufacturers developing machines equipped with IoT connectivity. This allows for real-time monitoring and analysis of equipment performance, enabling woodworkers to optimize their processes and reduce downtime. Additionally, the rise of automation is set to revolutionize production lines, providing bespoke solutions that cater to individual project needs while ensuring higher efficiency and precision.

Sustainability remains a critical focus, as the demand for environmentally friendly materials and practices continues to grow. In response, manufacturers are innovating machinery that uses less energy and produces minimal waste. Advanced woodworking tools are increasingly being crafted from recycled materials, and processes are designed to conserve resources. Moreover, the introduction of software solutions that simulate woodworking projects can help craftspeople design and plan more efficiently, minimizing material use and maximizing creativity. As these trends evolve, they will undoubtedly shape the woodworking industry's future, making it more adaptable and sustainable.

Revolutionary Technologies Shaping the Future of Woodworking Equipment

As the woodworking industry continues to evolve, revolutionary technologies are fundamentally shaping the future of woodworking equipment. The global woodworking machinery market is projected to reach approximately $11 billion by 2025, driven by advancements such as automation, smart technologies, and sustainable practices. According to a recent report from Research and Markets, the shift towards Industry 4.0 is already influencing machinery design, with an increasing emphasis on integration with the Internet of Things (IoT) for enhanced operational efficiency and real-time monitoring.

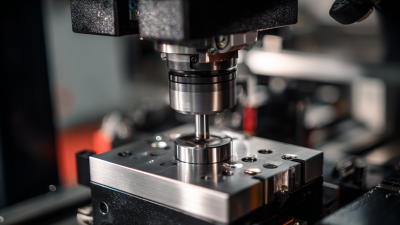

One of the most significant innovations is the integration of artificial intelligence (AI) in woodworking machinery. Systems equipped with AI can analyze performance data, predict maintenance needs, and optimize processes to reduce waste and improve product quality. Furthermore, advancements in CNC (Computer Numerical Control) technology allow for greater precision and versatility in woodworking operations, catering to the growing demand for customization in products. As we look to 2025, these technologies not only enhance productivity but also align with the industry's push toward more environmentally friendly practices, enabling manufacturers to meet stringent sustainability standards while maximizing efficiency.

Sustainable Innovations in Woodworking Machinery

The woodworking machinery industry is witnessing a significant transformation towards sustainability. With the global woodworking electric tools market projected to reach approximately $888.57 million by 2024 and the woodworking machinery market expected to expand to $40.07 billion by 2025, the drive for eco-friendly innovations becomes paramount. This growth trend reflects a broader industry commitment to environmental stewardship and promotes the development of machinery that minimizes waste and utilizes renewable materials.

Events like the upcoming China International Furniture Production Equipment and Ingredients Exhibition in Guangzhou exemplify this shift. Scheduled for March 2024, the exhibition will showcase cutting-edge technologies that focus on sustainable practices and innovations in woodworking machinery. Additionally, the visibility of environmentally responsible materials, such as high-performance minerals used in construction, marks a pivotal step towards a greener future in the industry. Embracing these innovations not only enhances efficiency but also aligns with a growing consumer demand for products that are both high-quality and environmentally friendly.

Smart Features to Enhance Efficiency in Woodworking Tools

As the woodworking machinery market is projected to reach a staggering $400.07 billion by 2025, with a CAGR of 6.74% until 2033, the focus on innovative technologies is more crucial than ever. One of the standout innovations in this sector is the introduction of smart edge banding machines. These machines are designed with advanced features, including a 10-inch smart touch panel that allows for seamless switching between different edge thicknesses. This not only enhances operational efficiency but also significantly reduces costs, marking a substantial leap forward for the furniture industry.

In addition to edge banding machines, the global market for electric woodworking tools is also on a growth trajectory, with estimates predicting a size of $888.57 million by 2024 and a steady increase of 5.5% till 2033. The integration of smart features into these tools is expected to streamline processes and optimize performance, reflecting the industry's commitment to technology-driven solutions. This blend of innovation and efficiency is paving the way for a more advanced and productive woodworking landscape, ensuring that businesses can meet the demands of a competitive market while maximizing output.

2025 Top 10 Woodworking Machinery Innovations You Can't Miss

| Innovation | Feature | Efficiency Improvement (%) | Sustainability Benefits |

|---|---|---|---|

| Automatic Feed Control | Adjusts feed rate based on material type | 30% | Reduces waste |

| Smart Dust Extraction | Real-time particle monitoring | 25% | Improves air quality |

| Robotic Arm Automation | Precision cutting and assembly | 40% | Minimizes human error |

| Integrated Software Solutions | Design and production sync | 35% | Enhanced material use |

| Wireless Machine Monitoring | Remote status updates | 20% | Efficient energy use |

| Advanced CNC Routers | Multi-material capability | 50% | Reduces energy consumption |

| Laser Cutting Systems | High precision and speed | 45% | Minimal waste generation |

| Augmented Reality Design Tools | Virtual prototypes for planning | 33% | Promotes recycling materials |

| Precision Measuring Tools | Digital gauges for accuracy | 28% | Less material wastage |

| Adaptive Saw Technology | Automatically adjusts blade angle | 38% | Increases tool life |

The Role of Automation in Modern Woodworking Processes

Automation is reshaping the woodworking industry, allowing manufacturers to increase efficiency, reduce waste, and enhance product quality. According to a report by the Association of Woodworking & Furnishings Suppliers (AWFS), companies that incorporate automation into their operations can see productivity gains of up to 30%. This shift towards automated solutions not only streamlines processes but also enables better tracking of material usage and machine performance, leading to more informed decision-making in production.

The integration of advanced technologies, such as CNC machines and robotic arms, is revolutionizing woodworking. For instance, a study by the Furniture Manufacturing Research Institute indicates that the implementation of CNC technology has resulted in a 50% reduction in labor costs and a significant decrease in production time. Moreover, these innovations facilitate greater customization options for consumers, which is essential in a market increasingly driven by specific consumer demands for personalized products. The ability to quickly adapt to market trends is essential for businesses, making automation a critical component of modern woodworking strategies.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts